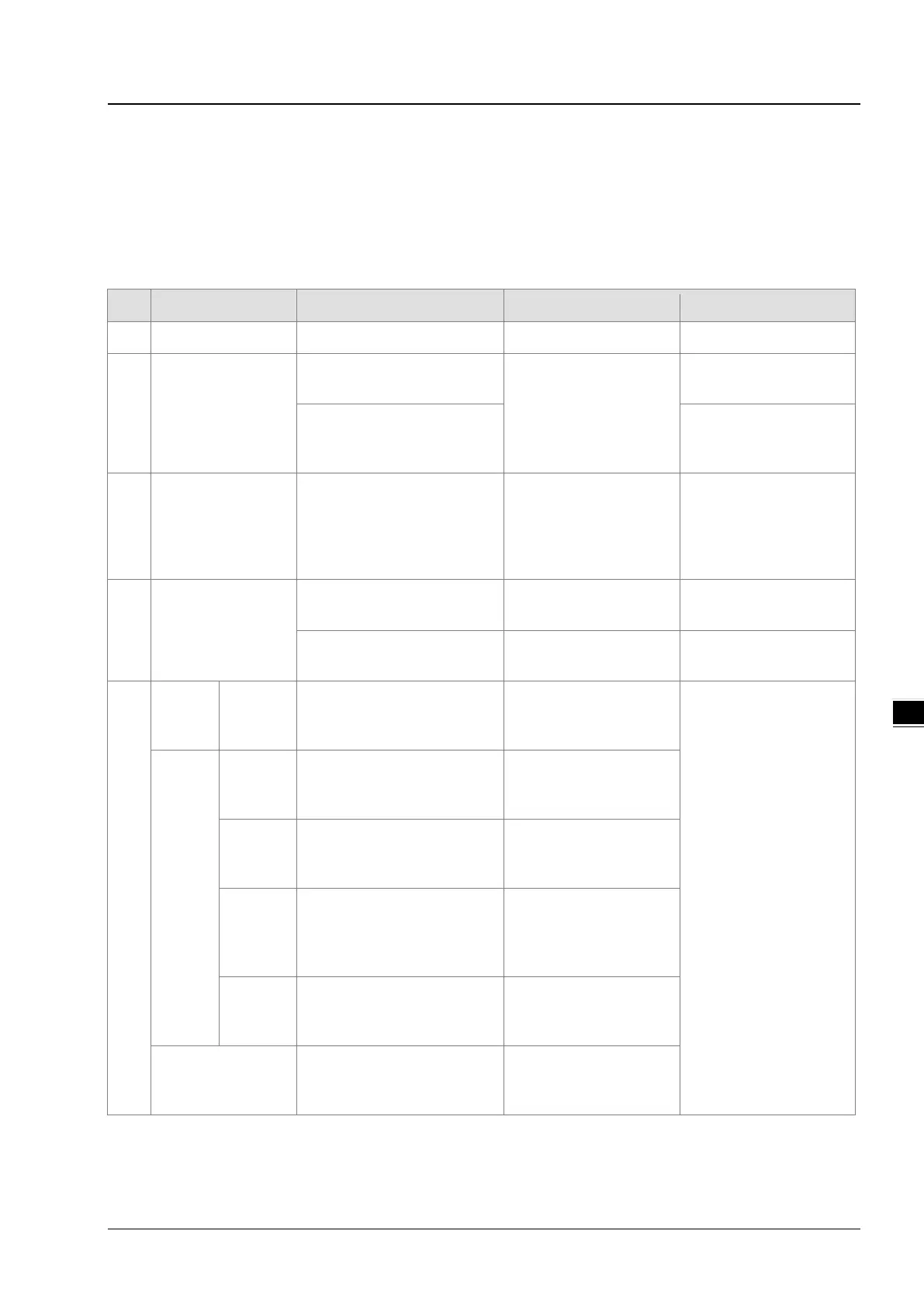

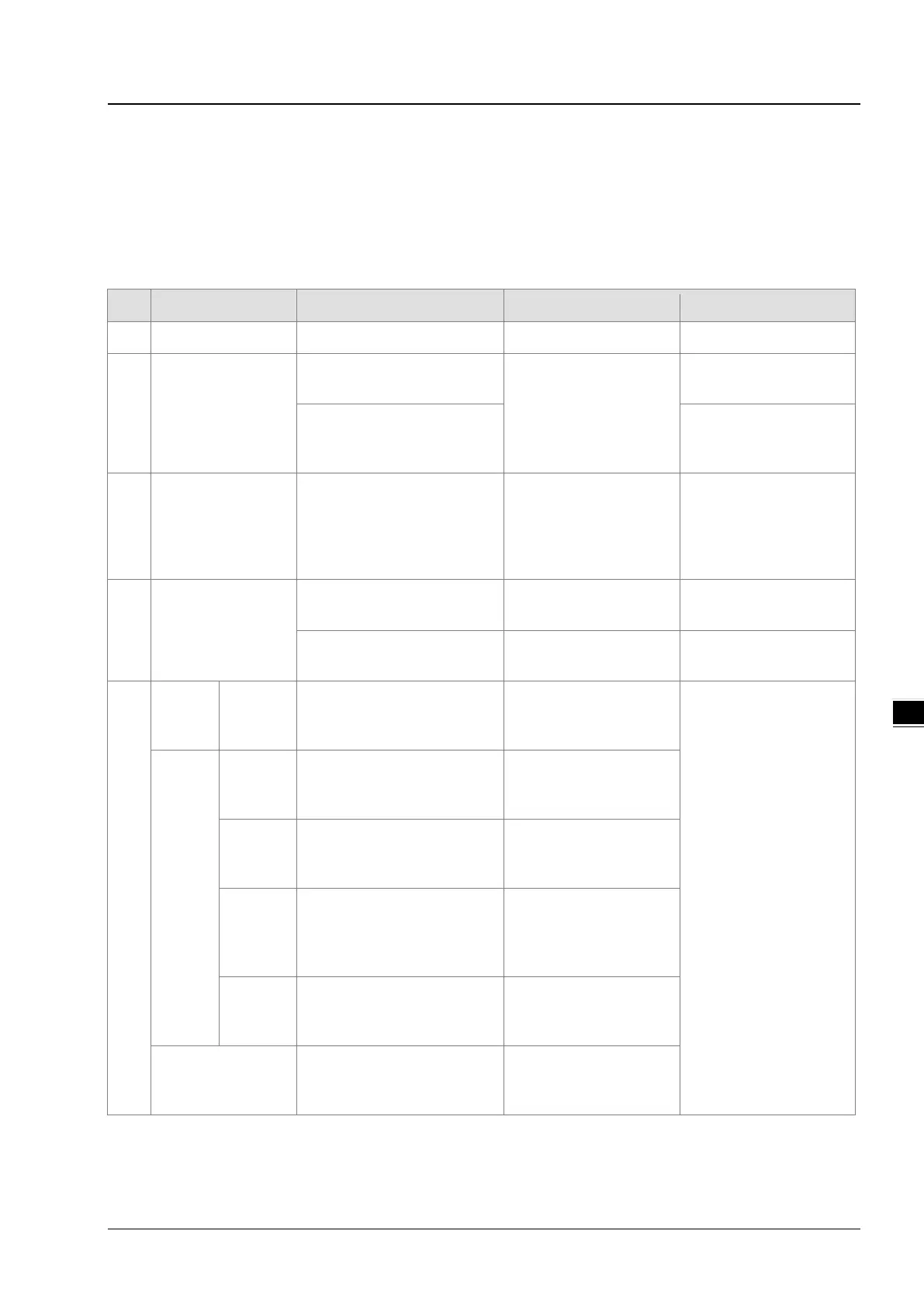

Chapter 5 Maintenance and Inspection

5-3

5.2.1 Tools Required for Inspection

A screwdriver

Industrial alcohol

A clean cotton cloth

5.2.2 Daily Inspection

Dirt must not be present.

2

Installation of a

backplane

Check whether the set screws

are loose.

The backplane must be

installed firmly.

Further tighten the screws.

Check whether the backplane is

installed on the DIN rail

Install the backplane on

the DIN rail properly.

3

Installation of a

module

Check whether the module is

loose, the projection is inserted

into the hole on the backplane,

and the screw is tightened.

The hook under the

module must be inserted

into the hole in the

backplane, and the screw

must be tightened.

Install the module firmly.

4 Connection

Check whether the removable

The removable terminal

Install the terminal block

Check whether the connector is

The connector should be

Further tighten the screws

5

Power

supply

module

POWER

LED

indicator

Check whether the POWER

LED indicator is ON.

The POWER LED

indicator must be ON.

Please refer to AH

Motion – Operation

Manual for more

information regarding

troubleshooting and error

logs.

CPU

module

RUN LED

indicator

When the CPU module is

running, check whether the

The RUN LED indicator

must be ON.

ERROR

LED

Check whether the ERROR

LED indicator is OFF.

must be OFF.

BUS

FAULT

LED

Check whether the BUS FAULT

LED indicator is OFF.

The BUS FAULT LED

indicator must be OFF.

SYSTEM

LED

Check whether the SYSTEM

LED indicator is OFF.

The SYSTEM LED

indicator must be OFF.

LED indicators on an

extension module

Check whether the LED

indicators on the extension

module are ON.

If the LED indicators are

ON, the module operates

normally.

* Please refer to AH500 Module Manual for more information related to the LED indicators on the extension modules.

Loading...

Loading...