What does Delta Servo Drives encoder initial magnetic field error mean?

- PPatricia ColeSep 2, 2025

Encoder initial magnetic field error in Delta Servo Drives indicates that the magnetic field of the encoder U, V, W signal is in error.

Loading...

Loading...

What does Delta Servo Drives encoder initial magnetic field error mean?

Encoder initial magnetic field error in Delta Servo Drives indicates that the magnetic field of the encoder U, V, W signal is in error.

What does Delta ASDA-B2-F Servo Drives early warning for overload mean?

Early warning for overload in Delta Servo Drives signifies an early warning for overload condition.

What does Delta ASDA-B2-F Servo Drives serial communication timeout mean?

A serial communication timeout in Delta Servo Drives means that RS-232 communication has timed out.

What does Delta ASDA-B2-F Servo Drives serial communication error mean?

A serial communication error in Delta Servo Drives means that RS-232 communication is in error.

What does Delta Servo Drives abnormal signal output mean?

An abnormal signal output in Delta Servo Drives means that the encoder output exceeds the rated output frequency.

What does Delta ASDA-B2-F reverse limit error mean?

A reverse limit error in Delta Servo Drives means that the reverse limit switch is activated.

What does Delta ASDA-B2-F forward limit error mean?

A forward limit error in Delta Servo Drives means that the forward limit switch is activated.

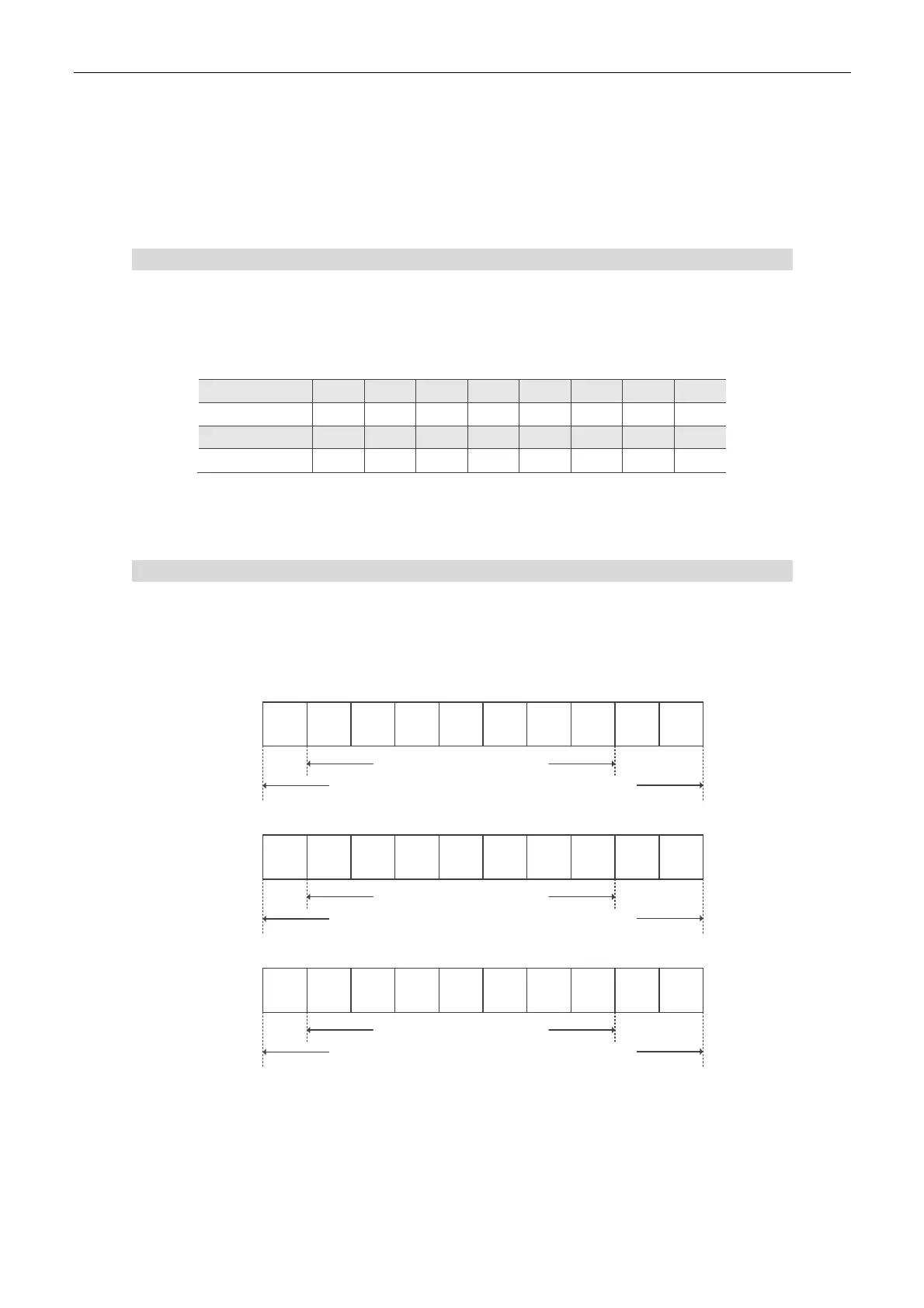

| Model | ASDA-B2-F Series |

|---|---|

| Power Range | 0.1kW to 3kW |

| Control Modes | Position, Speed, Torque |

| Protection Class | IP20 |

| Type | Servo Drives |

| Communication Interface | RS-485, CANopen |

| Feedback Resolution | 17-bit |

| Protection Features | Overvoltage, Undervoltage, Overcurrent |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -20°C to 65°C |

| Certifications | CE, UL |

| Input Voltage | 200VAC ~ 230VAC, Single/Three Phase; 100VAC ~ 120VAC, Single Phase (Specific models) |

| Humidity | 90% RH or less (non-condensing) |

Procedure to check the servo drive and motor for damage and correctness before operation.

Details on understanding the nameplate information for servo drives and motors.

Table matching servo drive models with their corresponding servo motors for proper system configuration.

Identification and description of the various parts and terminals of the servo drive unit.

Key points and precautions to observe during installation for proper operation and to prevent damage.

Specifies the recommended environmental conditions for installing the servo drive.

Guidelines on mounting orientation and required clearance for optimal cooling and ventilation.

Guidance on selecting appropriate EMI filters based on servo drive models and power.

Information on selecting built-in and external regenerative resistors based on servo drive specifications.

Diagrams and instructions for connecting external devices like power, contactors, and controllers.

Detailed explanation of the terminal signals and connectors on the servo drive unit.

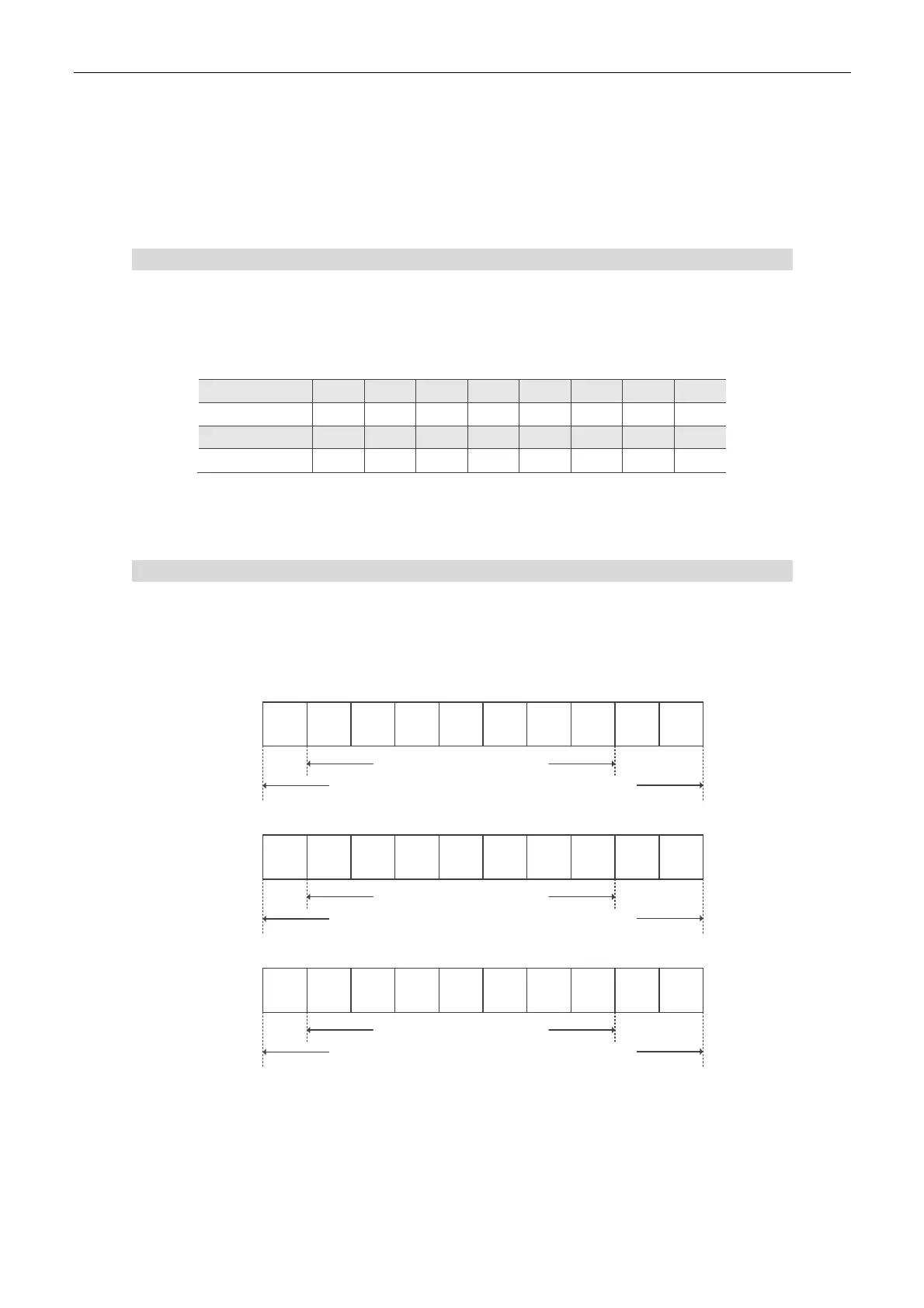

Illustrates basic wiring diagrams for different servo drive models and power configurations.

Details on the I/O signal connector, including terminal layout and signal explanations.

Information on the DMCNET communication connector, its pin assignments, and function.

Overview of the servo drive's front panel, including displays and key functions.

Step-by-step guide on how to navigate and change parameters using the control panel.

Explanation of various status displays, including save status, decimal points, and alarm messages.

Procedure for operating the servo motor in JOG mode for testing and setup.

Procedures for inspecting the servo motor and drive without load to ensure safety and proper function.

Instructions for applying power to the servo drive and checking initial status displays and warnings.

Procedure for performing a basic test run of the motor using JOG mode without any load.

Detailed steps for estimating inertia ratio and performing auto or semi-auto tuning.

Step-by-step flowchart illustrating the process of auto tuning the servo system.

Methods to suppress mechanical resonance using Notch filters and manual adjustments.

Overview of the three basic operation modes: Position, Speed, and Torque, and how to select them.

Details on using the servo drive in position mode, including control structure and command processing.

Explanation of speed control mode, including command selection, structure, and filters.

Methods and parameters for suppressing resonance in the servo system.

Description of torque control mode, including command selection and control structure.

Guidance on the operation and timing of the motor brake controlled by the servo drive.

Explanation of parameter groups, naming conventions, and special symbol descriptions.

A detailed list of all parameters, their functions, default values, and control mode compatibility.

Description of monitor parameters used for observing servo drive status and variables.

Details on fundamental parameters for configuring servo drive operation and limits.

Configuration parameters for advanced functions like loop gains, filters, and suppression.

Parameters for setting up serial communication protocols, speed, and addresses.

Parameters related to diagnosing servo drive status, faults, and digital I/O.

Parameters for configuring motion control aspects like acceleration, deceleration, and software limits.

Details on the hardware interface and wiring for RS-232 serial communication.

Configuration of essential RS-232 communication parameters like address, speed, and protocol.

Explanation of MODBUS communication modes (ASCII, RTU), character structure, and data frames.

Information on setting and accessing parameters via communication for various groups.

List and description of servo drive alarms, their corresponding DO signals, and servo status.

Details on alarms related to DMCNET communication errors and status.

List of alarms specific to motion control functions and their corrective actions.

Troubleshooting guide listing common causes for alarms and recommended corrective actions.

Specifications, precautions, and dimensions related to battery boxes and wiring for absolute encoders.

Instructions for installing the battery box and connecting it to the servo drive and motor.

List of parameters that are relevant to the absolute servo system configuration and operation.

Procedures for system initialization, accessing absolute position, and handling coordinate systems.

Detailed electrical and mechanical specifications for the ASDA-B2-F servo drive series.

Comprehensive specifications for ECMA series servo motors, including performance and dimensions.

Torque-speed (T-N) curves illustrating the performance characteristics of ECMA series servo motors.

Information on overload protection mechanisms and graphs showing load vs. operating time.

Dimensional drawings and specifications for various ASDA-B2-F servo drive models.

Dimensional drawings and specifications for ECMA series servo motors of different frame sizes.

Details and part numbers for various power connectors used with the servo system.

Specifications and part numbers for different power cables, including lengths and connector types.

Details on encoder connectors, including part numbers and pin configurations.

Part numbers and specifications for connection cables designed for absolute encoders.

Dimensional diagrams and part numbers for Battery Box Cable AW.

Dimensions and part numbers for single and dual battery boxes used with absolute encoders.

Details on the PC connection cable used for software communication and setup.

List of optional accessories available for ASDA-B2-F series servo drives and motors.

Routine checks for the servo drive and motor, including tightening screws and cleaning.

Guidelines for proper product storage, cleaning ventilation ports, and general maintenance practices.

Information on the expected lifetime of key components like DC bus capacitors, relays, and cooling fans.