Chapter 2 Engineering Design of Servo Mechanism

12

Chapter 2 Engineering Design of Servo Mechanism

2.1 Designing the Servo Mechanism

2.1.1 Example of the Mechanism

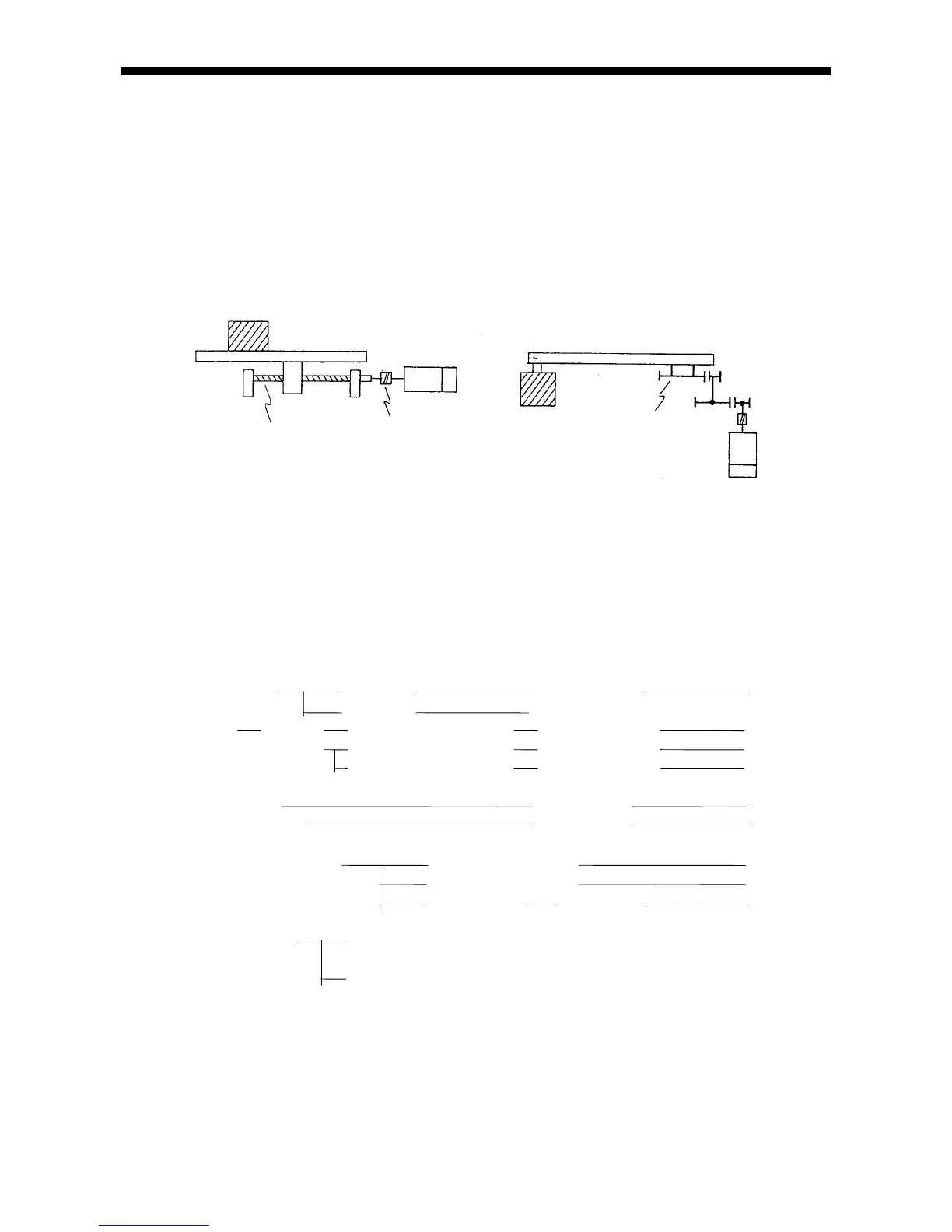

The mechanism is classified into a linear movement section and a revolving arm section as shown

in Fig. 2-1.

(a) Linear movement section (b) Revolving arm

Fig. 2-1 Example of the mechanism

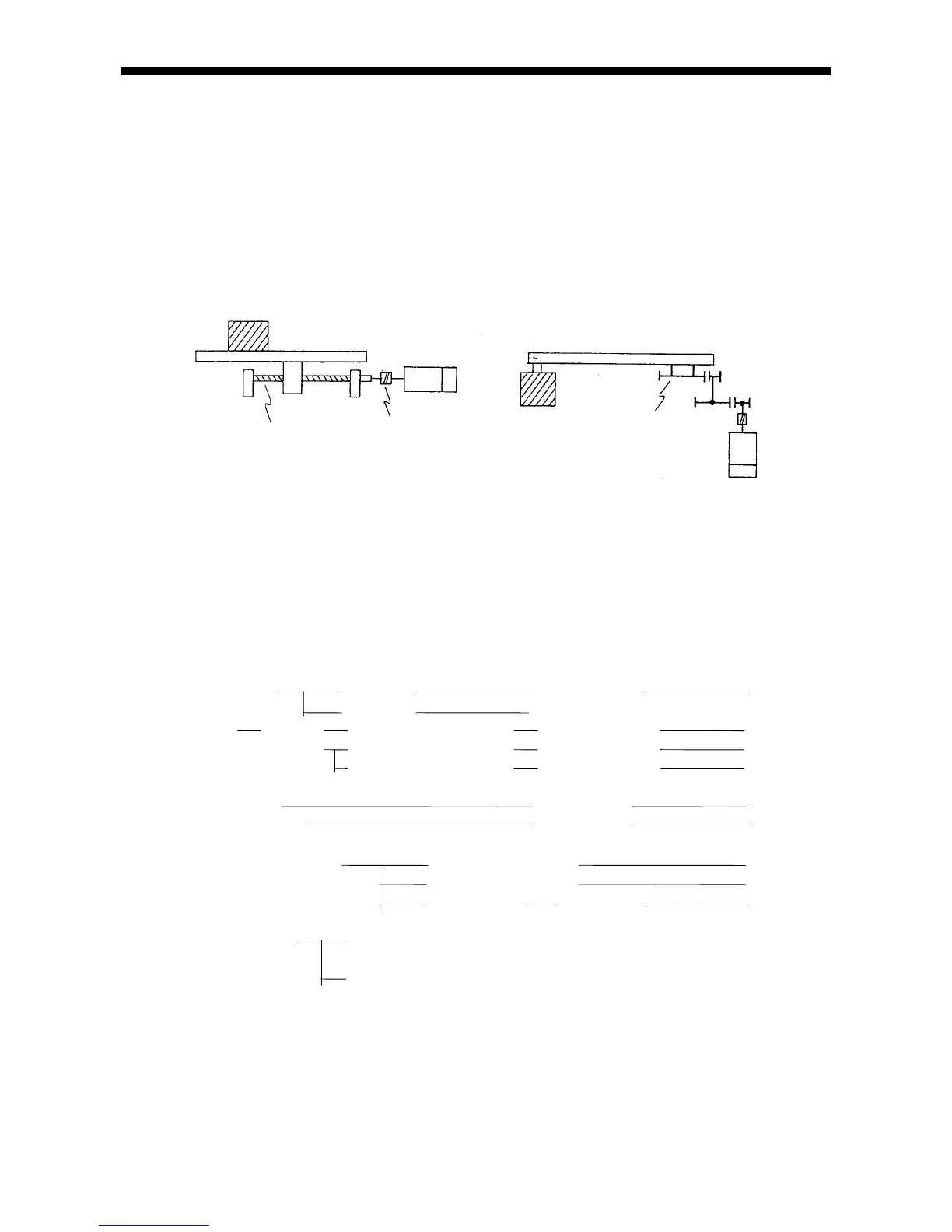

2.1.2 Selection of the Drive System

An appropriate control cannot be performed if a rapid torque fluctuation occurs due to stick slip

or the like.

Typical appropriate and inappropriate examples of the drive system are as shown below:

Ball screw Grinding Backlash small

Rolling Backlash large (Control instable)

Gear Grinding Accuracy grade 1 or higher Backlash small

Cutting Accuracy grade 3 or higher Backlash medium

Accuracy grade 4 or lower Backlash large

Screw shaft Friction large

Harmonic drive Friction large

(Care for selection)

Slide section bearing linear motion bearing

LM guide

Slide bearing

Seal, packing Friction: 20% or less of the rated torque in conversion

into the motor shaft's

Friction: More than 20% of the rated torque in conversion

into the motor shaft's

denotes "Appropriate"

denotes "Conditionally appropriate"

denotes "Inappropriate"

Ball screw, etc.

Load

Moto

Loading...

Loading...