Chapter 4 Configuring the Joint Parameters

48

4.3.1 Setting the Speed Reduction Rate in Manual Operation

The speed reduction rate in manual operation can be limited to 10% or below of that

in automatic operation.

This section provides the reduction rate calculation procedure using the maximum

composite tool-end speed and the target speed in manual operation.

NOTE: For details, refer to the ISO 10218-1:2006, Safety Requirements.

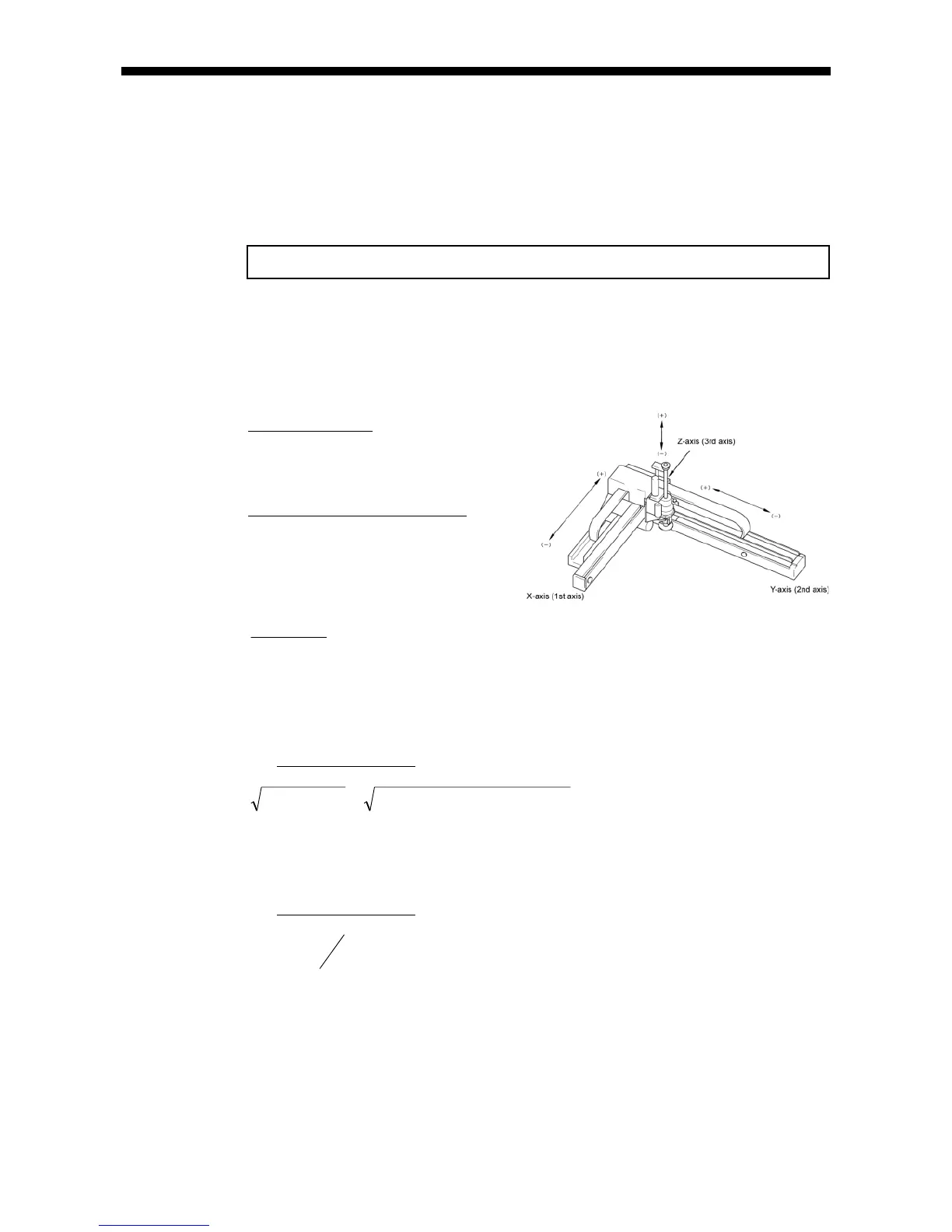

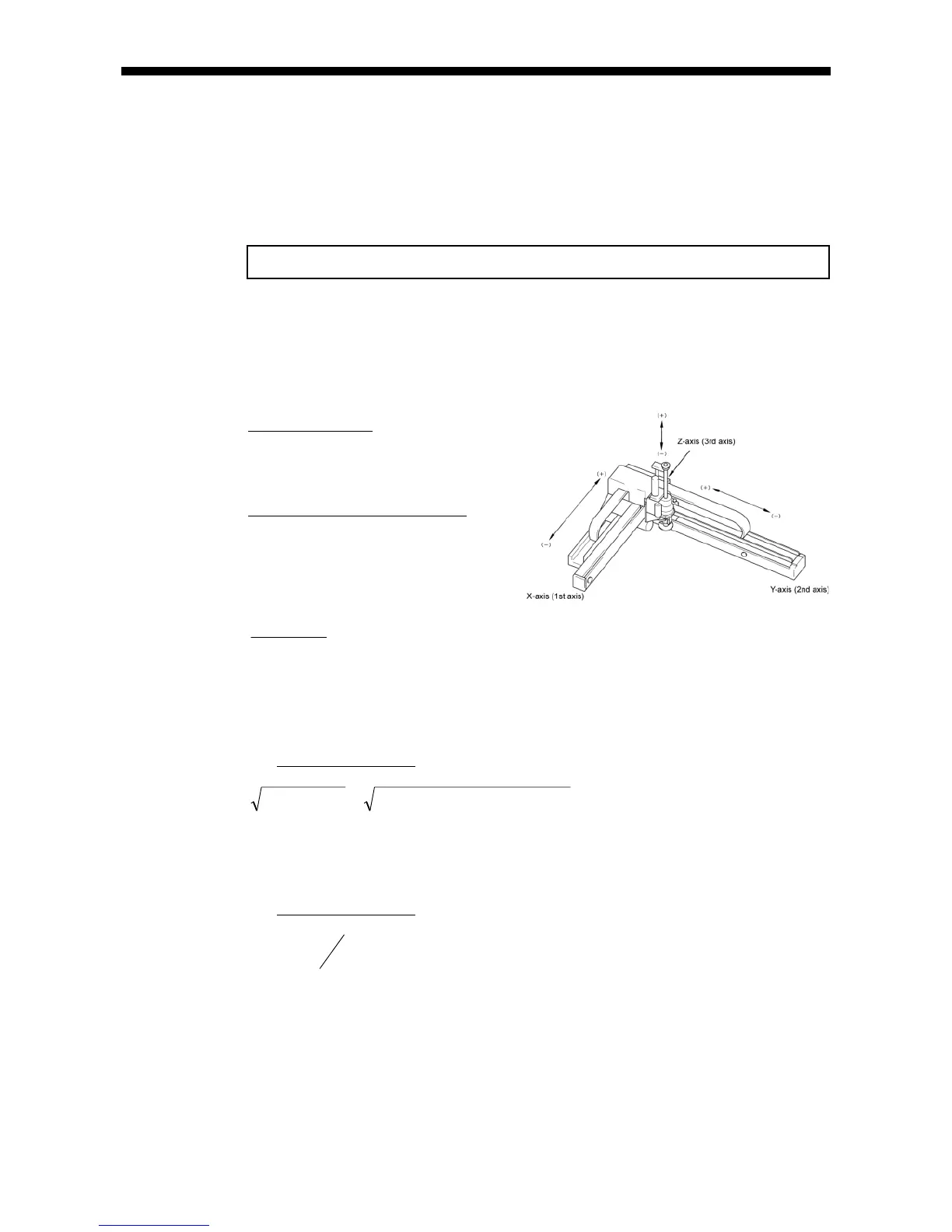

The example below uses a 3-joint mechanism configured with Cartesian coordinates

and limits the tool-end speed in manual operation to 250 mm/s or below.

(1) Check the specifications of the 3-joint mechanism and calculate the maximum

speed of each joint.

3-joint mechanism

X-joint: Max. speed 2000 mm/s

Y-joint: Max. speed 2000 mm/s

Z-joint: Max. speed 1000 mm/s

Calculating the maximum speed

Assuming:

Lead/rev.: 40 mm

Maximum motor rotation: 3000 rpm,

Then:

]/[2000

]/[40

60

][3000

smm

revmm

rpm

(2) Calculate the maximum composite tool-end speed.

Calculation example

]/[3000)1000()2000()2000(

222222

smmzyx

(3) Calculate the speed reduction rate in manual operation to limit the tool-end

speed to 250 mm/s or below.

Calculation example

8100

]/[3000

]/[250

smm

smm

(%) (Truncate the decimal places.)

(4) Enter the calculation result into the "Speed reducing rate in manual operation"

field in the ArmSet window shown on the previous page.

Loading...

Loading...