Chapter 2 Engineering Design of Servo Mechanism

14

[Selection of screw shaft dia., lead and nut]

1) Selection of lead (l)

From the max. speed of DC motor

l

V

N

max

max

1000 60

20 (mm)

3000

Select from among accuracy large lead products of 20 mm or longer lead.

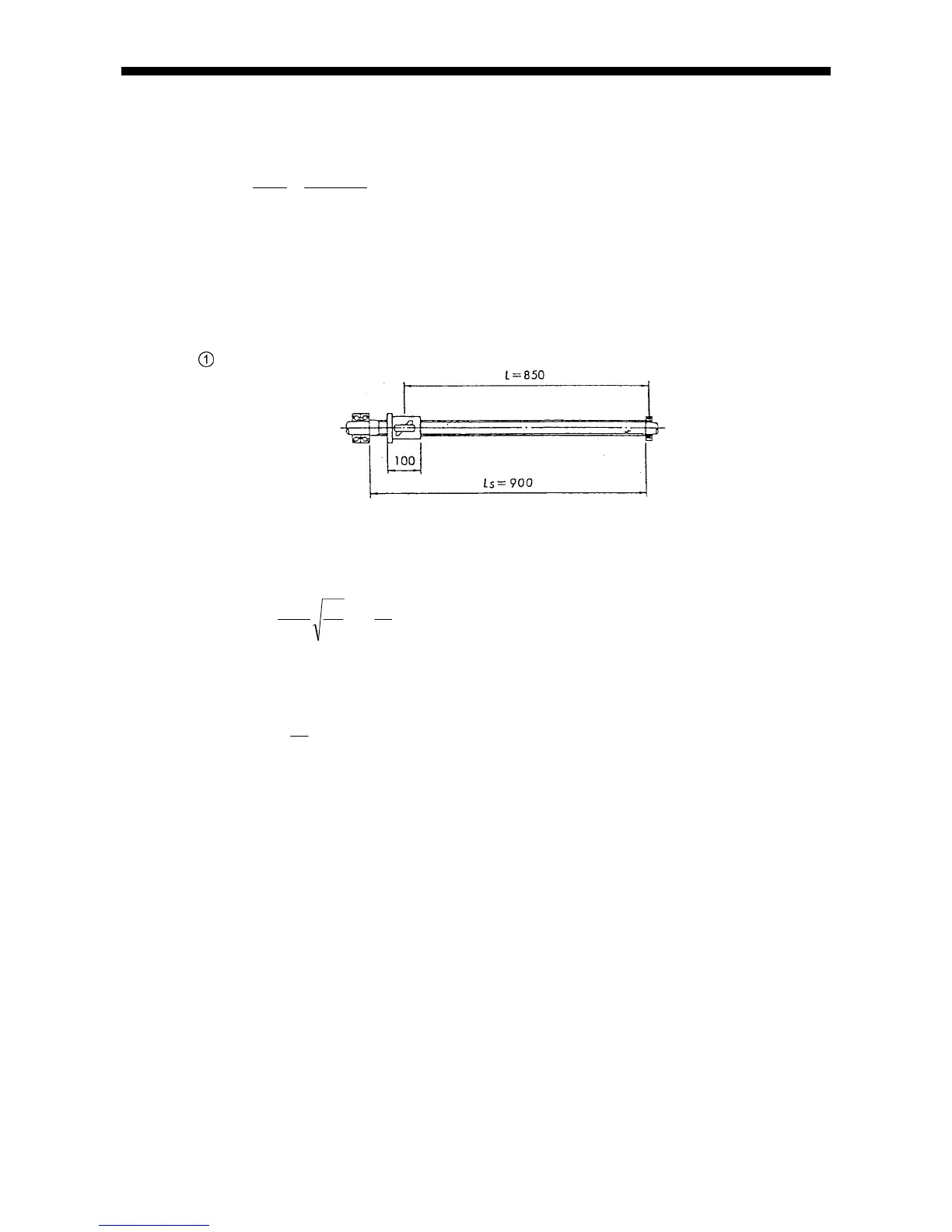

2) Temporary selection of thread length

Ls = max. stroke + nut length + shaft end allowance

= 700 + 100 + 100 + 900 (mm)

3) Selection of screw shaft dia.

Select the shaft dia. by checking the allowable speed with a high speed feed. The bearing

support construction shall be of the most general fixing-support one.

Dangerous speed

Fig. 2-4. Selection of thread length

An examination is required for the ball screw speed not to resonate with the intrinsic number of

vibrations of the screw shaft. The allowable speed shall be 80% or less of this dangerous speed.

na

L

EI

A

f

dr

L

60

2

10

2

22

7

(rpm)

········································································· (1)

where

a: Safety factor (a = 0.8)

E: Modulus of longitudinal elasticity (E = 2.06

× 10

4

kPa)

I: Minimum secondary moment of the screw shaft cross section

Idr

64

4

(mm )

4

dr: Screw shaft minor dia. (mm) <See Dimension Table>

r: Specific weight of the material (r = 7.8

× 10

-6

kg/mm

3

)

A: Screw shaft cross-sectional area (A =

dr

2

/4 mm

2

)

L: Distance between mounting points (mm)

f,

: Factor fixed by the mounting method of the ball screw

Support – support f = 9.7 (

)

Fixing – support f = 15.1 (

3.927 )

Fixing – fixing f = 21.9 (

4.730 )

Fixing – freedom f = 3.4 (

1.875 )

Loading...

Loading...