Chapter 2 Engineering Design of Servo Mechanism

21

3) Motor rated torque (T

R

)

Refer to motor catalog.

4) Evaluation

() .TT

N

N

T

PD R

1

2

02≦

T

P

: Friction torque by external load (Nm)

T

D

: Friction torque by pre-load (Nm)

T

R

: Motor rated torque (Nm)

N

1

: The number of gear A teeth

N

2

: The number of gear B teeth

5) Others

It is recommended to use the grinding ball screw. Rolling ball screw has so large backlash that it

may not move properly.

[ 2 ] Gear sliding resistance

Table 2-3 shows gear transmission efficiency

Use gear of which transmission efficiency is 98% or more except for skew gears. In this case,

sliding resistance of gear (friction torque) can be disregarded.

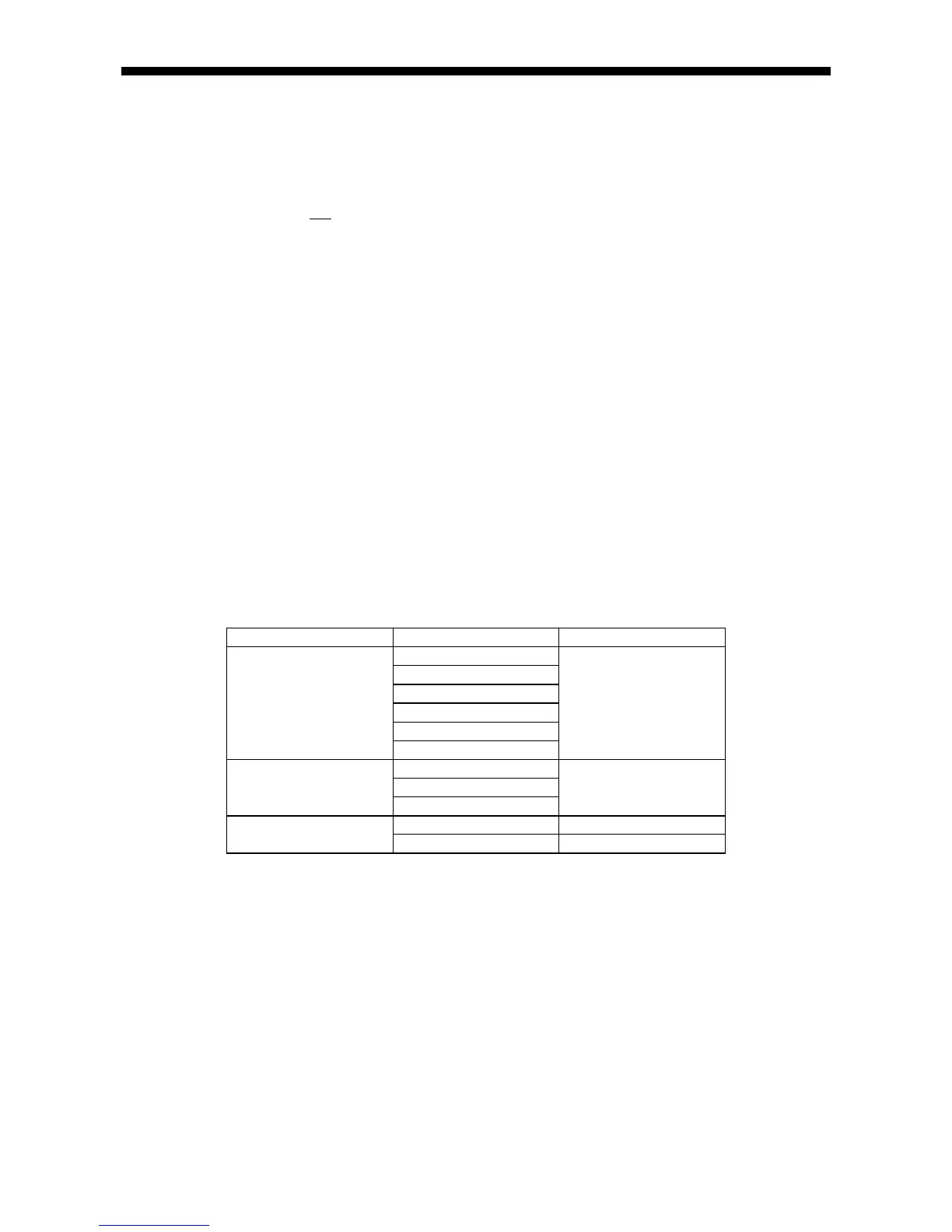

Table 2-3. Classification and type of gear

Classification of gear Type of gear Efficiency (%)

Spur gear

Rack

Parallel axis Internal gear 98.0 - 99.5

Helical gear

Helical rack

Double helical gear

Straight bevel gear

Intersecting axis Spiral bevel type gear 98.0 - 99.0

Zerol bevel gear

Skew axis Cylindrical worm gear 30.0 - 90.0

Crossed helical gear 70.0 - 95.0

Loading...

Loading...