Chapter 3 Choosing AC Servomotors

40

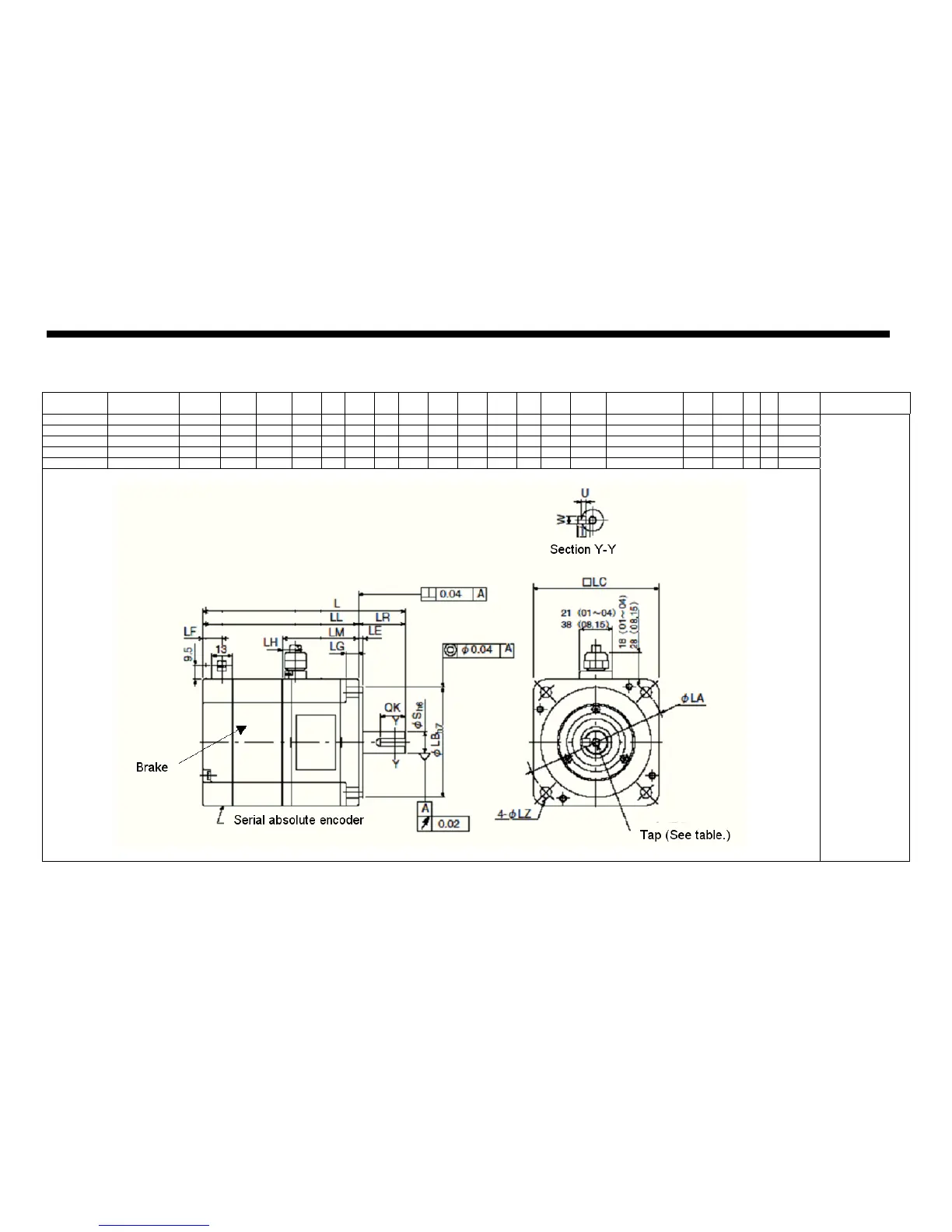

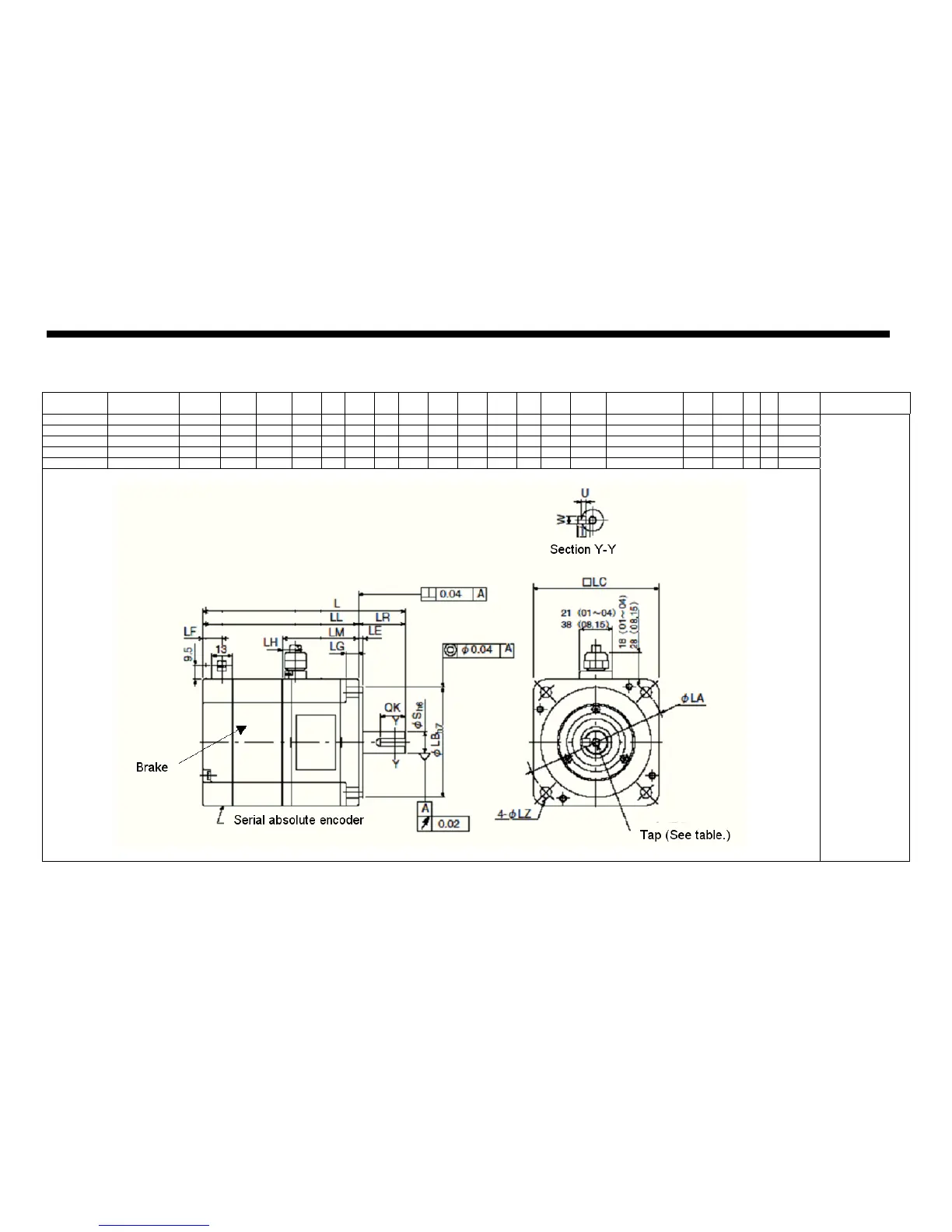

■Flat type with brake [100W, 200W, 400W, 750W or 1.5kW]

Part No.

Motor model

SGMPH-

Rated

output

L LL LM LR LE LG LF LC LA LZ S LB LH Tap QK U W T

Approx

weight

Remarks

410627-0260 01A1A–DH2* 100W 116.0 91.0 42.5 25 3 6 12.5 60 70 5.5 8 50 10.55 Dia. 3, Depth 6 14 1.8 3 3 0.9 kg

410627-0270 02A1A–DH2* 200W 128.5 98.5 48.1 30 3 8 11.9 80 90 7 14 70 8.25 Dia. 5, Depth 8 16 3 5 5 1.9 kg

410627-0280 04A1A–DH2* 400W 148.5 118.5 68.1 30 3 8 11.9 80 90 7 14 70 8.25 Dia. 5, Depth 8 16 3 5 5 2.6 kg

410627-0290 08A1A–DH2* 750W 163.0 123.0 66.7 40 3.5 10 12.8 120 145 10 16 110 10.5 Dia. 5, Depth 8 22 3 5 5 5.7kg

410627-0300 15A1A–DH2* 1.5kW 188.0 148.0 94.7 40 3.5 10 12.8 120 145 10 19 110 10.5 Dia. 6, Depth 10 22 3.5 6 6 8.1kg

(Unit: mm)

(1) Assembly

accuracy conforms

to Japan Machine

Tool Builder's

Association

standard

(MAS402-1981).

(TIR value)

a) Shaft end

deflection: 0.03

(Shaft projection

center)

b) Squareness of

flange face against

shaft 0.08 (45)

c) Eccentricity of

flange-fitting-outsid

e diameter against

shaft (Spigot joint

portion center)

(2) Flange fixing

bolt:

Use hexagon

socket head bolt.

(3) Motor cable /

Encoder cable

length: 300 mm

Loading...

Loading...