EN-36 Originalbetriebsanleitung Allgemein

23.5 Cable brakes: adjusting the brake cable

tension

Warnings

Serious falls and accidents caused by reduced braking

power.

▪ Brake cables are wear parts. Check these for wear

and tear regularly, and replace the brake cables if

necessary.

The brake cable connects the brake lever to the brakes. It

is made of steel or aluminium, and is located in a brake

sleeve. If you have completely applied the hand brake

but do not have full braking force, all you need to do is to

tighten the brake cable, assuming there is little wear on the

brake pads. This reduces the distance between the brake

shoes and rim (rim brakes) or between the brake lining and

brake disc (disc brakes) and compensates for slight wear

on the brake pads. However, if the brake pads are severely

worn, these must be replaced 23.6 Replacing the brake

pads Page EN-36.

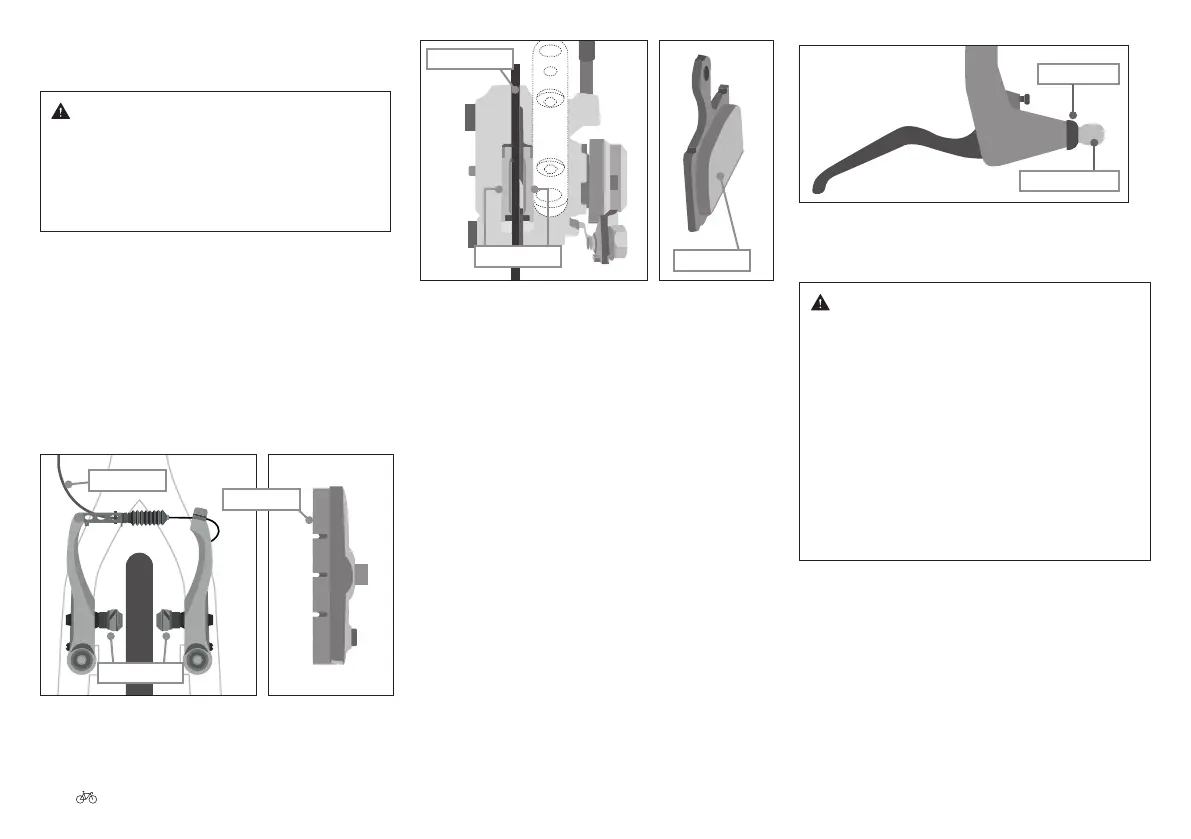

Fig. 51 Rim brakes Fig. 52 Brake shoe

Brake shoes

Brake cable

Brake lining

Fig. 53 Disc brakes Fig. 54 Brake lining

Brake pads

Brake disc

Brake lining

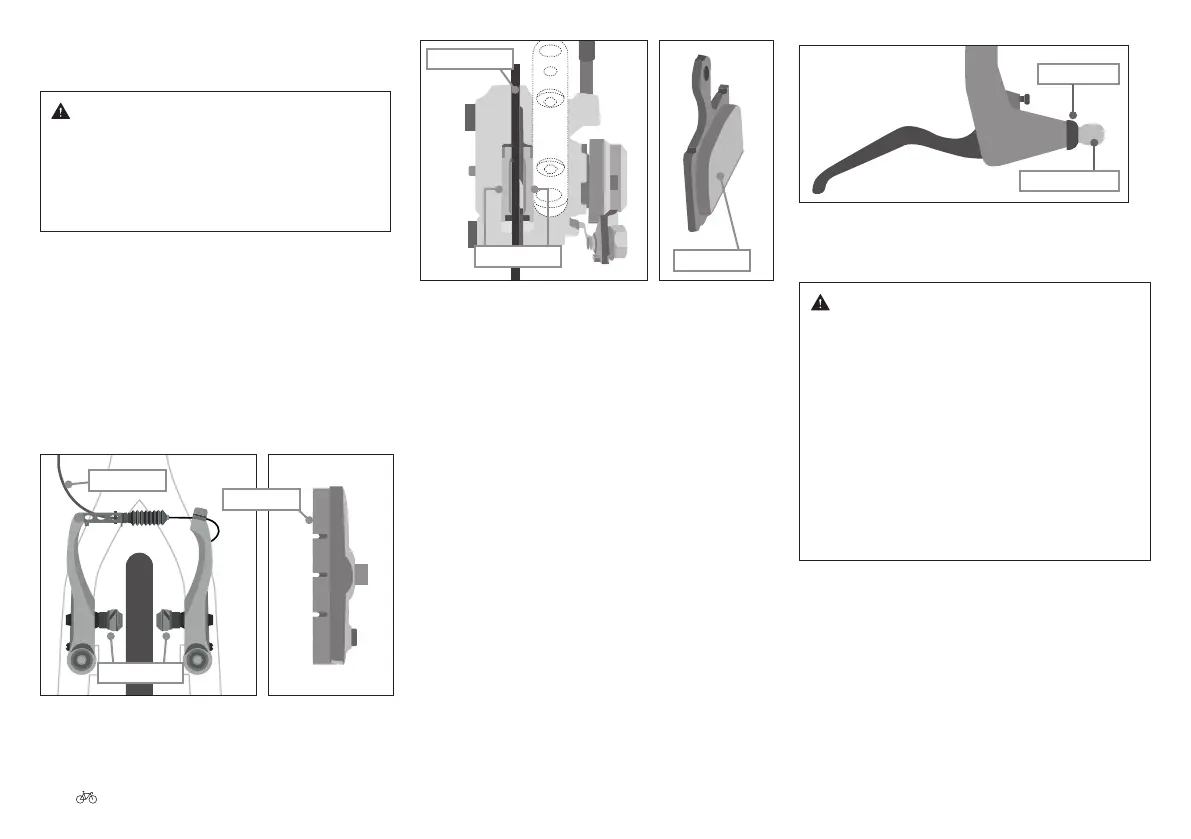

Most brake levers have screws to adjust the length and

tension of the brake cables. To adjust the tension, proceed

as follows:

1. Unscrew the lock nut a few turns counterclockwise.

2. Rim brake: To increase the tension, you must now

unscrew the adjustment screw counterclockwise step

by step until the distance between the brake shoes

and rim is 1-2 mm on each side. Make sure that the

brake shoes contact the two sides of the rim or brake

disc at the same time. To reduce the tension, turn the

adjustment screw clockwise.

2. Disc brake: To increase the tension, you must now

unscrew the adjustment screw counterclockwise step

by step until the desired pressure point is reached on

the brakes

23.4.3 Changing the pressure point Page EN-35.

To reduce the tension, turn the adjustment screw

clockwise.

3. Finally, retighten the lock nut clockwise.

If there is still no braking eect, the brake pads probably

need to be replaced

23.6 Replacing the brake pads Page EN-36.

Fig. 55 Brake cable tension adjustment screw

Adjustment screw

Lock nut

23.6 Replacing the brake pads

Warnings

Serious falls due to lack of bicycle control.

▪ The appropriate brake pads must be used in order to

obtain the right friction pairing.

Carbon: Particularly on carbon rims, only pads that

are expressly intended for this purpose may be used.

▪ Brake pads may not come into contact with oil

or grease. Otherwise, this will impair braking

performance.

Have the brake pads replaced if they have come into

contact with oil or grease.

▪ Do not ride your bicycle if the brake pads are worn

out. Have these replaced in a specialist workshop.

Brake pads are friction agents on brake shoes (rim brakes)

or carrier plates (disc brakes), and are therefore wear

parts. If they are worn out, they must be replaced, as the

braking force decreases as a result of wear. On rim brakes,

you can notice wear as the brake lever must be drawn

further and further towards the handlebars when braking

in order to achieve a braking eect. Brake pad wear on disc

brakes produces a metallic scratching sound, which only

appears when the brake lining is already completely worn

Loading...

Loading...