EN-52 Originalbetriebsanleitung Allgemein

Tighten

Tensioning lever

Clamping

nut

Springs

Axle

Fig. 116 Quick-release skewer on the wheel

1. Open the tensioning lever by folding it by 180˚. OPEN

should now be visible.

2. Check that the wheel is correctly positioned.

3. Close the tensioning lever by swinging the lever by

180˚. CLOSE should now be visible. The lever should

be very easy to move from the beginning of the closing

movement up to halfway. Then, the force required to

move the lever must signicantly increase until the

lever is very dicult to move at the end.

4. a) If the quick-release skewer closes too easily, the

pre-tension must be increased: Hold the tensioning

lever and turn the clamping nut on the opposite side

clockwise. Check whether the correct pre-tensioning

has been achieved by closing the tensioning lever.

b) If the quick-release skewer is too dicult to close,

the pre-tension must be reduced: Hold the tensioning

lever and turn the clamping nut on the opposite

side counterclockwise. Check whether the correct

pre-tensioning has been achieved by closing the

tensioning lever.

5. Close the tensioning lever. The lever must be

positioned in such a way that it cannot be opened

accidentally.

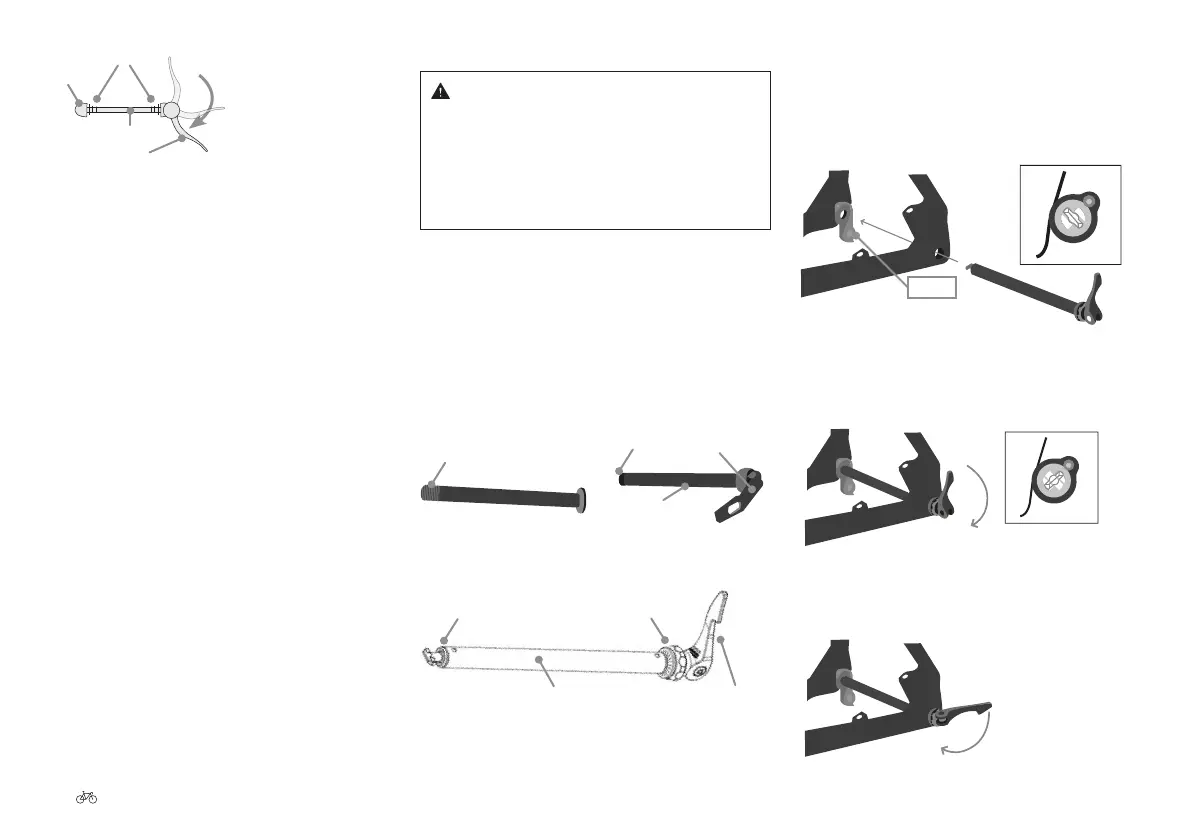

27.2 Attaching wheels with through-axles

Warning

Serious falls due to loose components.

▪ Close the lever as described. Otherwise, the wheel

may become loose while cycling, and you run the

risk of very serious or even fatal injuries. If you are

unsure, have a specialist workshop show you this

setting.

Through-axles are similar to quick-release skewers. While

quick-release skewers in wheels are pushed through the

axle of the hub, through-axles are themselves the axle.

Unlike quick-release skewers, they have a threaded

connection rather than a clamping nut. Through-axles can

the completely screwed on, or can rst of all be screwed on,

and then tightened using a lever, as on a quick-release

skewer. A further option is to attach the wheel using a

T-piece, which is then secured by means of a lever (e.g.,

R.A.T. through-axle).

Thread

Fig. 117 Through-axle Fig. 118 Through-axle with lever

Thread Tensioning lever

Axle

T-piece

Rotary wheel

Axle Tensioning lever

Fig. 119 R.A.T. through-axle

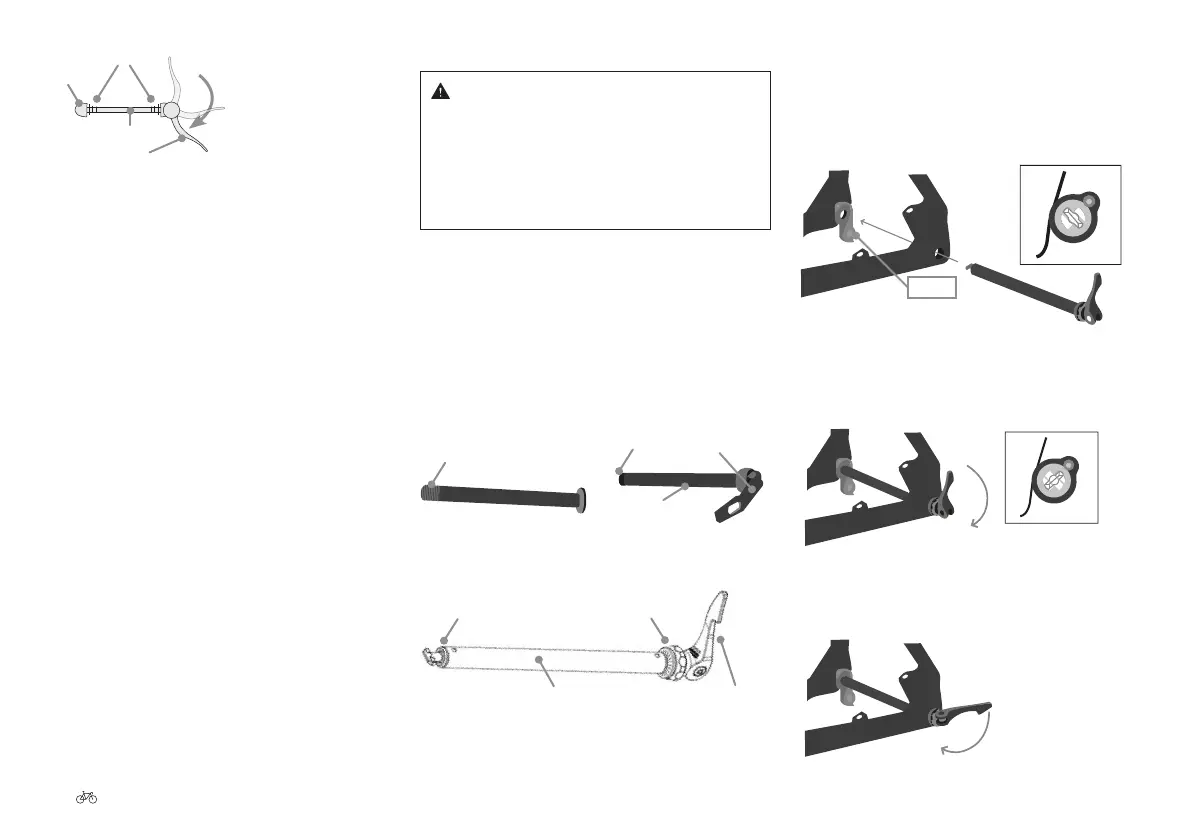

27.2.1 Mounting a R.A.T. through-axle

1. Insert the R.A.T. axle with the lever in the open

position through the frame/fork and wheel, until the

T-piece at the end of the R.A.T. axle penetrates the

insert on the other side.

Insert

Fig. 120 Insert the through-axle

2. Turn the lever 90° clockwise until the T-piece hits the

insert. The axle should turn easily, and it should no

longer be possible to pull it out of the frame.

Fig. 121 Rotate the lever clockwise

3. Once the axle is in position, ip the lever to tension

the system.

Fig. 122 Tension the lever

Loading...

Loading...