Instructions for use Polaris 600 87

Maintenance

Checking the locking devices on the

spring arm

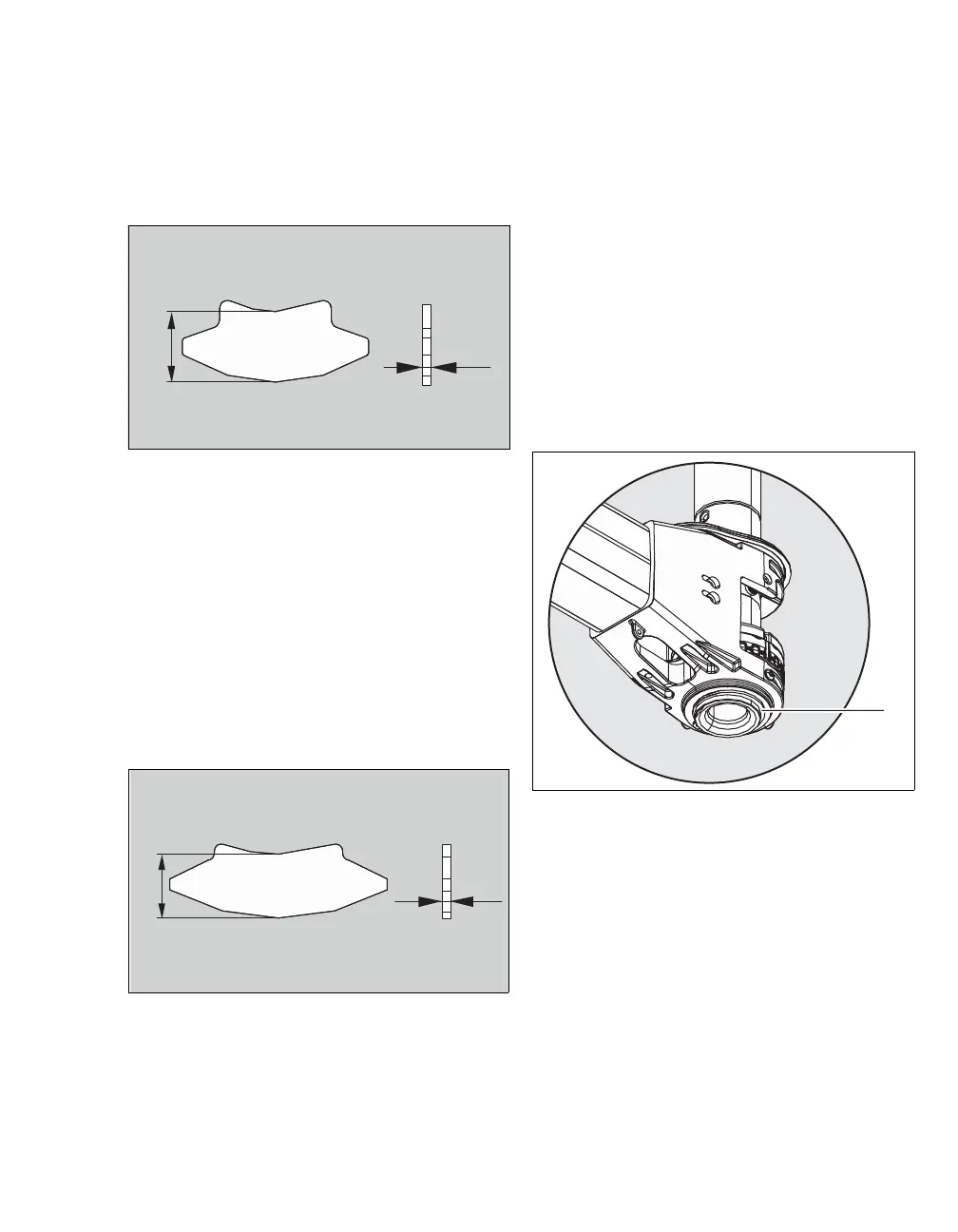

Spring arm types C/S L3 and C/S D

– Remove/fit the locking devices in accordance

with the technical documentation.

The 2 locking devices on each spring arm must

be checked for length and material thickness.

The locking device must be replaced if it does

not meet specifications.

The length (A) of the locking device must be at

least 8.3 mm (0.327 in).

The material thickness (B) of the locking device

must be at least 1.8 mm (0.071 in).

Grease the 2 locking devices on each spring

arm with microGLEIT GP 360 paste.

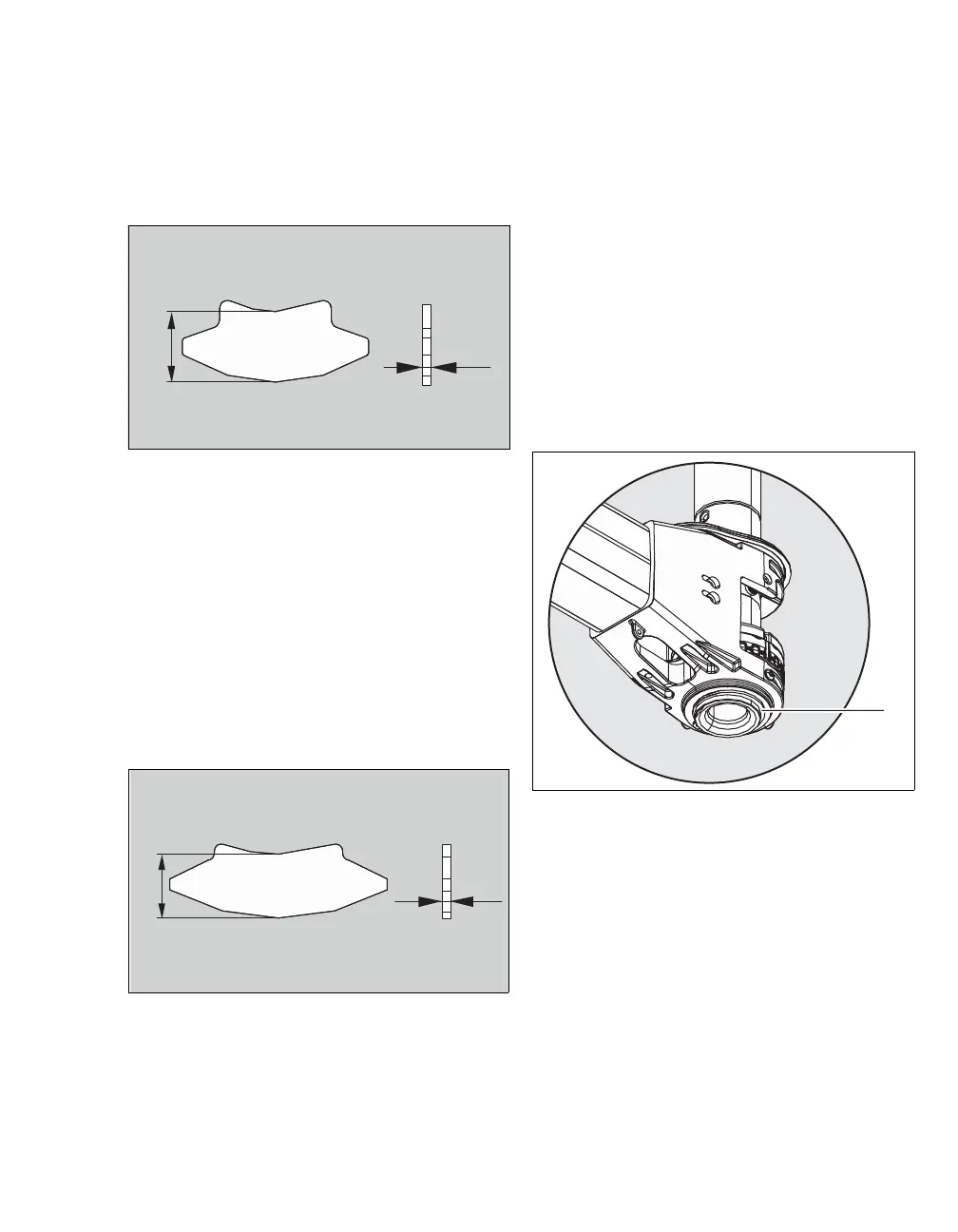

Spring arm types C/S D+ and CD+

– Remove/fit the locking devices in accordance

with the technical documentation.

The 2 locking devices on each spring arm must

be checked for length and material thickness.

The locking device must be replaced if it does

not meet specifications.

The length (A) of the locking device must be at

least 8.7 mm (0.343 in).

The material thickness (B) of the locking device

must be at least 1.8 mm (0.071 in).

Grease the 2 locking devices on each spring

arm with microGLEIT GP 360 paste.

Checking the circlip on the lower swivel

arm to the spindle joint

– Check the circlip in accordance with the

technical documentation.

The circlip (A) must be undamaged and the

seal intact. If there is damage to the circlip or

the seal, the circlip must be replaced.

Greasing the brake screws

Greasing the brake screws on the swivel arm and

the spring arm

– Remove/fit the 2 brake screws in accordance

with the technical documentation.

Grease the 2 brake screws with microGLEIT

GP 360 paste.

5368553686

53688

A

Loading...

Loading...