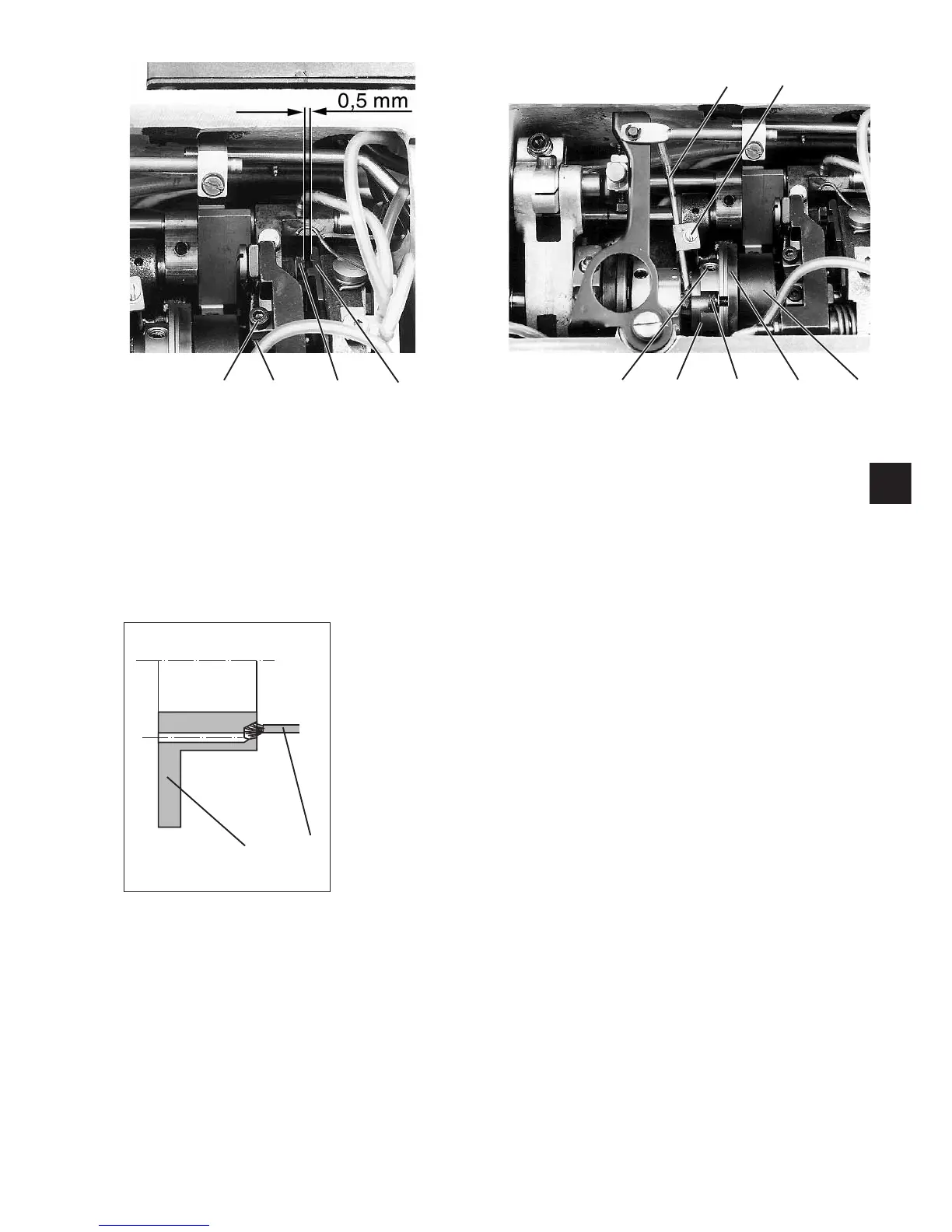

Position of the release block

–

Loosen screw 1.

–

Turn block 2.

With the vertical cutter turned on, the c learance between the

release block 3 and the latch 4 should be 0.5 mm.

The block 2 should not touch the arm s haft.

–

Tighten screw 1 again.

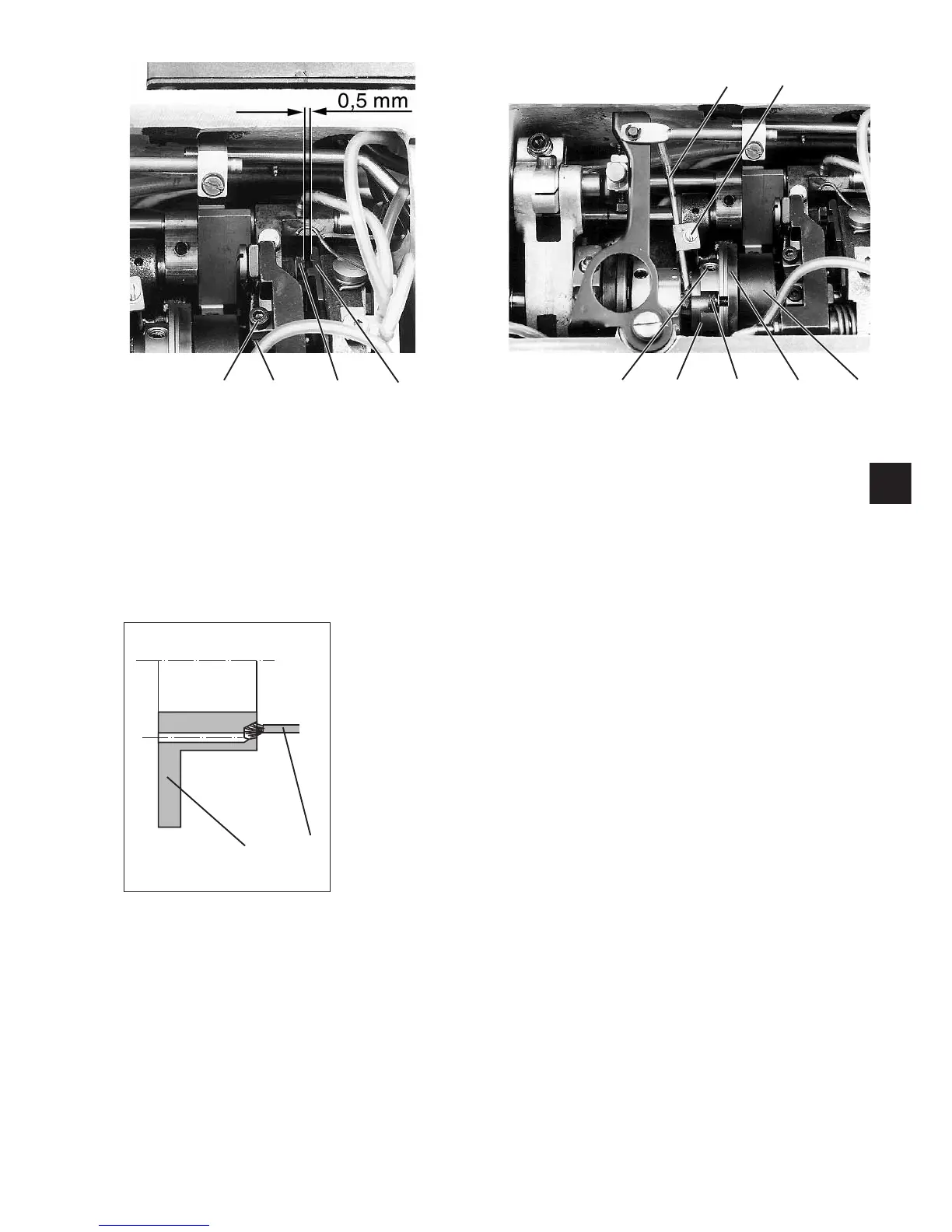

Lubrication of the eccentric

–

Loosen screw 6.

–

Set the position of the oil tube 5.

The wick must touch the groove in the eccentric with its knots.

–

Tighten screw 6 again.

Stroke of the knife

–

Loosen screws 9 (3 x).

–

Set the position of the eccentric sleeve 10 in the radial direction.

The stroke (8 to 12 mm) should be appropriate to the material

thickness.

Astrokeof8mmissetatthefactory.

–

Tighten screws 9 (3 x) again.

–

Correct the knife overlap.

(see further down in this Chapter)

Timing of the knife movement

–

Loosen screws 7 (2 x).

–

Tu rn eccentric 8 on the shaft.

The knife and the presser foot should r each their upper dead

centers at the same time.

–

Tighten screws 7 (2 x) again.

The tie rod 11 must sit centered on the running face of the eccentric

without touching the shoulder of the e ccentric.

The wick must touch the groove in the eccentric with its knots.

89

GB

12 3 4

78 91011

56

85

Loading...

Loading...