63

Dynaset Oy | Menotie 3, FI-33470 Ylöjärvi, Finland | tel: +358 3 3488 200 | info@dynaset.com | www.dynaset.com

HYDRAULIC SCREW COMPRESSORS

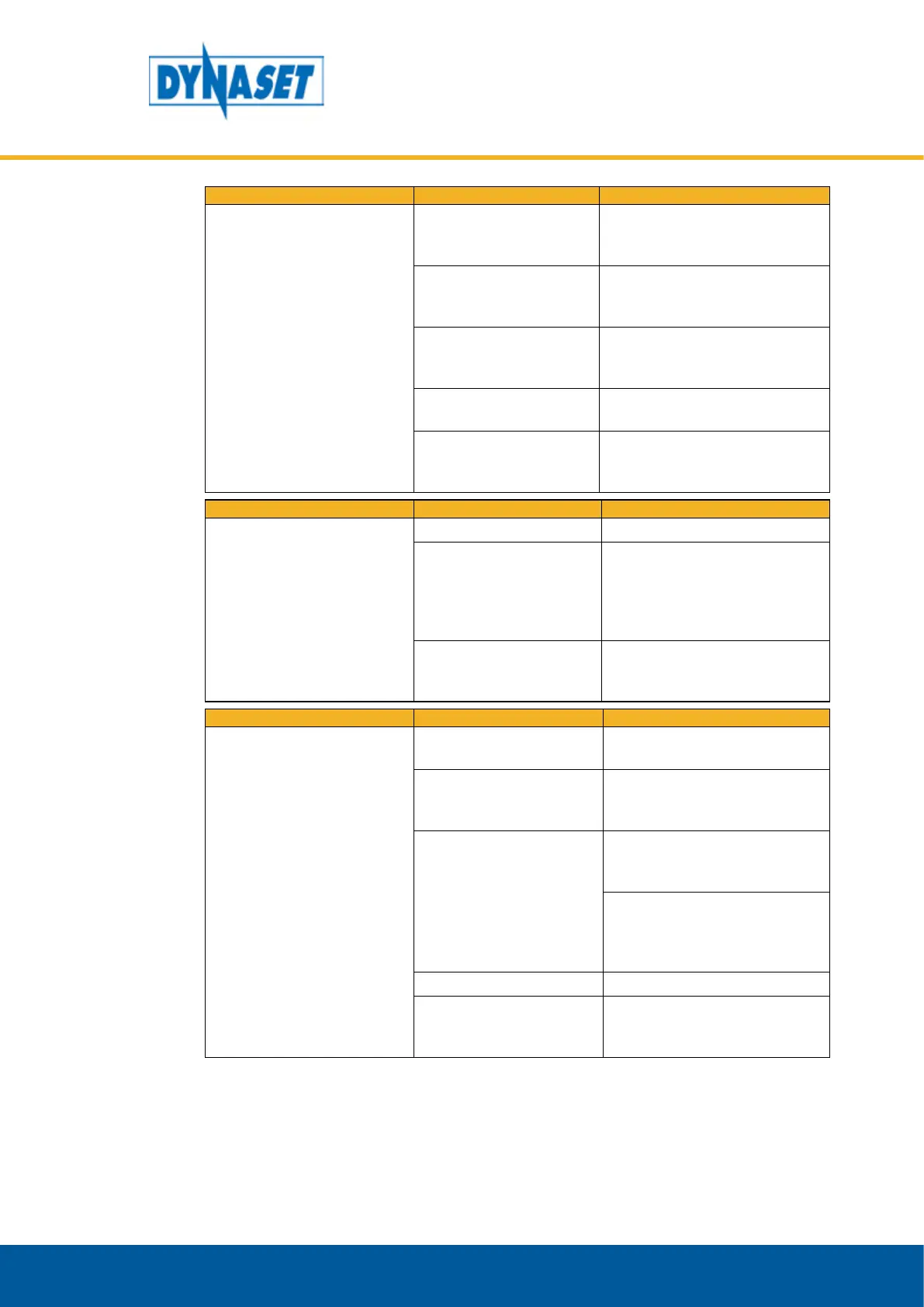

MAINTENANCE

FAILURE REASON CORRECTIVE ACTION

Excessive compressor oil

consumption or oil in air

delivery line.

Lubrication nozzle in

compressor oil return line

clogged or faulty.

Check. Replace nozzle if

necessary.

Compressor oil return line

check valve clogged or

faulty.

Check. Replace check valve if

necessary.

Air-oil separating

element(s) clogged or

faulty.

Check. Replace air-oil separating

element(s) if necessary.

Oil level too high.

Check oil level. Drain and replace

oil if necessary.

Operating pressure and

delivery quantity are not

in the permissible range.

Check hydraulic pressure and

ow. Adjust if necessary.

FAILURE REASON CORRECTIVE ACTION

Compressor does not

produce compressed air.

Delivery line is closed. Check.

Air pressure control valve

failure or incorrect setting

(i.e. adjusted pressure

is lower than setting of

minimum pressure valve).

Check. Adjust if necessary.

Air intake valve does not

open.

Check the valve and air pressure

control valve. Replace parts if

necessary.

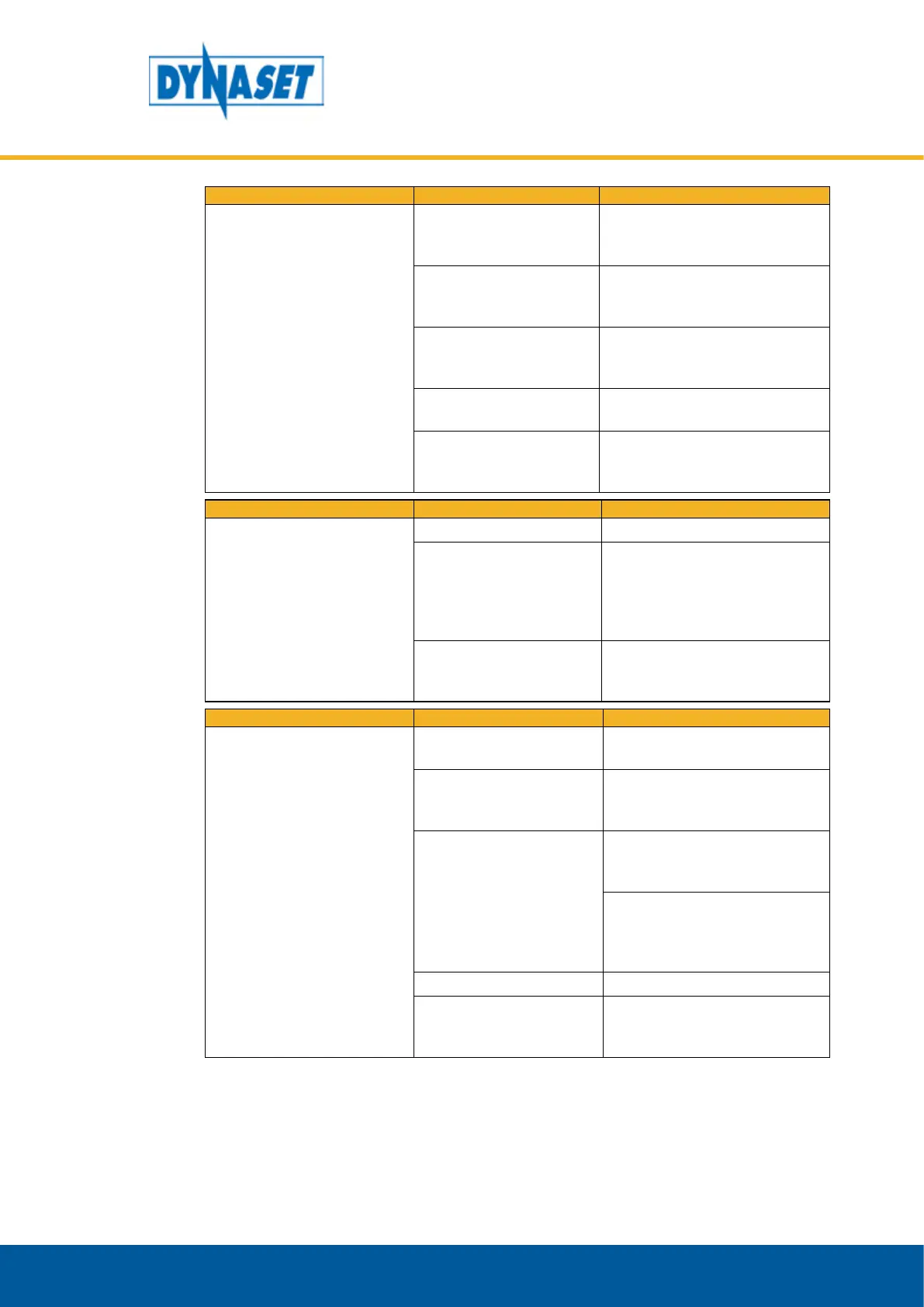

FAILURE REASON CORRECTIVE ACTION

Air pressure does not achive

requested rate.

Air pressure control valve

incorrect setting.

Check. Adjust if necessary.

Safety valve opens due

the incorrect setting of air

pressure control valve.

Check. Adjust air pressure

control valve if necesasry.

Failure in hydraulic system.

Check that hydraulic pressure

and ow are sucient. Adjust if

necessary.

Check that hydraulic motor of

the compressor for possible

leakage. Replace shaft seal if

necessary.

Air intake lter clogged. Check. Replace lter.

Air-oil separating

element(s) clogged of

faulty.

Check. Replace air-oil separating

element(s) if necessary.

Loading...

Loading...