64

Dynaset Oy | Menotie 3, FI-33470 Ylöjärvi, Finland | tel: +358 3 3488 200 | info@dynaset.com | www.dynaset.com

HYDRAULIC SCREW COMPRESSORS

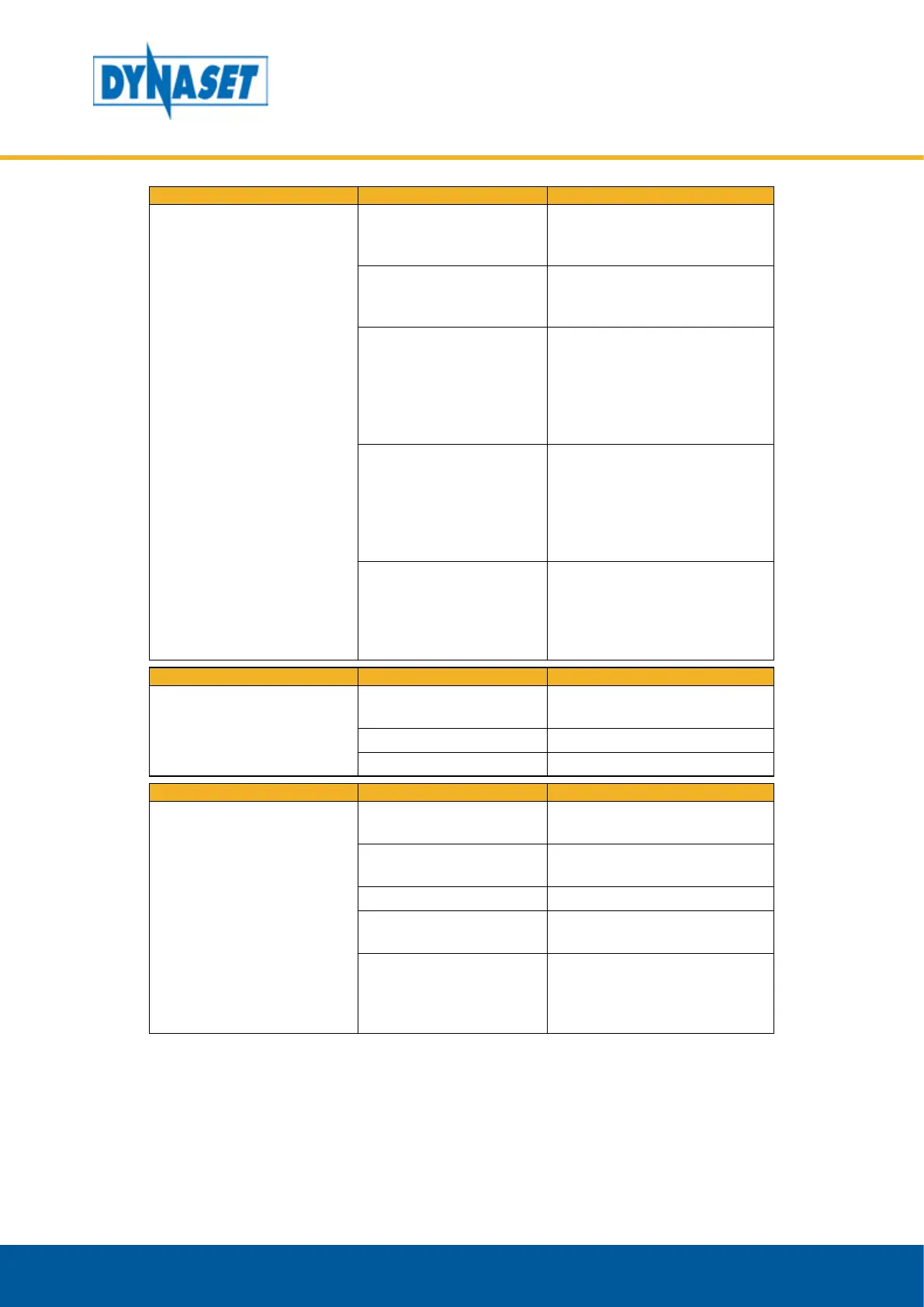

MAINTENANCE

FAILURE REASON CORRECTIVE ACTION

Compressor is over heating

Insucient cooling

capacity of hydraulic

system.

Check and ensure sucient

cooling capacity if nesessary.

High ambient temperature.

Check installation location of

compressor. Arrange sucient

cool intake air for compressor.

Compressor oil does

not circulate through

heat exchanger due the

incorrect operation of

faulty thermostatic by-pass

valve.

Check. Replace thermostatic by-

pass valve if necessary.

Compressor oil does

not circulate through

heat exchanger due the

incorrect operation of

faulty heat exchanger by-

pass valve.

Check. Replace heat exchanger

by-pass check valve if necessary.

Insucient cooling

capacity.

Check. Improve cooling capacity

if necessary.

Dynaset oy oers wide range of

hydraulic components including

oil coolers.

FAILURE REASON CORRECTIVE ACTION

Compressor is over heating.

Oil level is too low.

Check the oil level. Fill if

necessary.

Oil lter soiled. Replace oil lter cartridge.

Oil thermostat faulty. Replace oil thermostat.

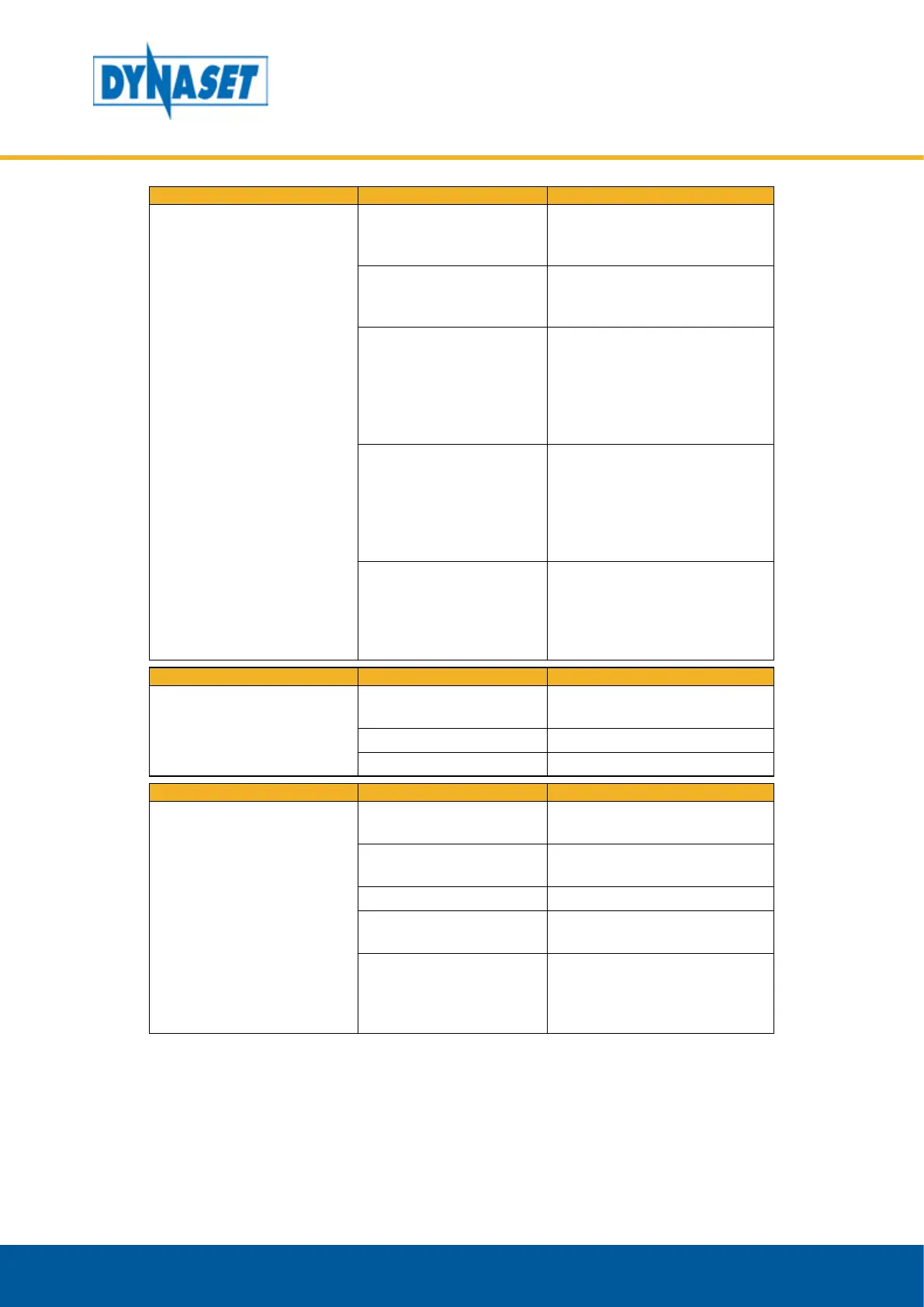

FAILURE REASON CORRECTIVE ACTION

Safety valve blows o (at

a permissible operating

pressure).

Safety valve pressure

setting too low.

Chack. Adjust if necessary.

Air-oil separating element

dirty-

Replace air-oil separating

element.

Safety valve defective. Replace safety valve.

Pressure control valve

setting too high.

Check and adjust if necessary.

Incorrect operation of

minimum pressure valve.

Check minimum pressure

valve for smooth movement;

if necessary ensure smooth

operation or replace.

Loading...

Loading...