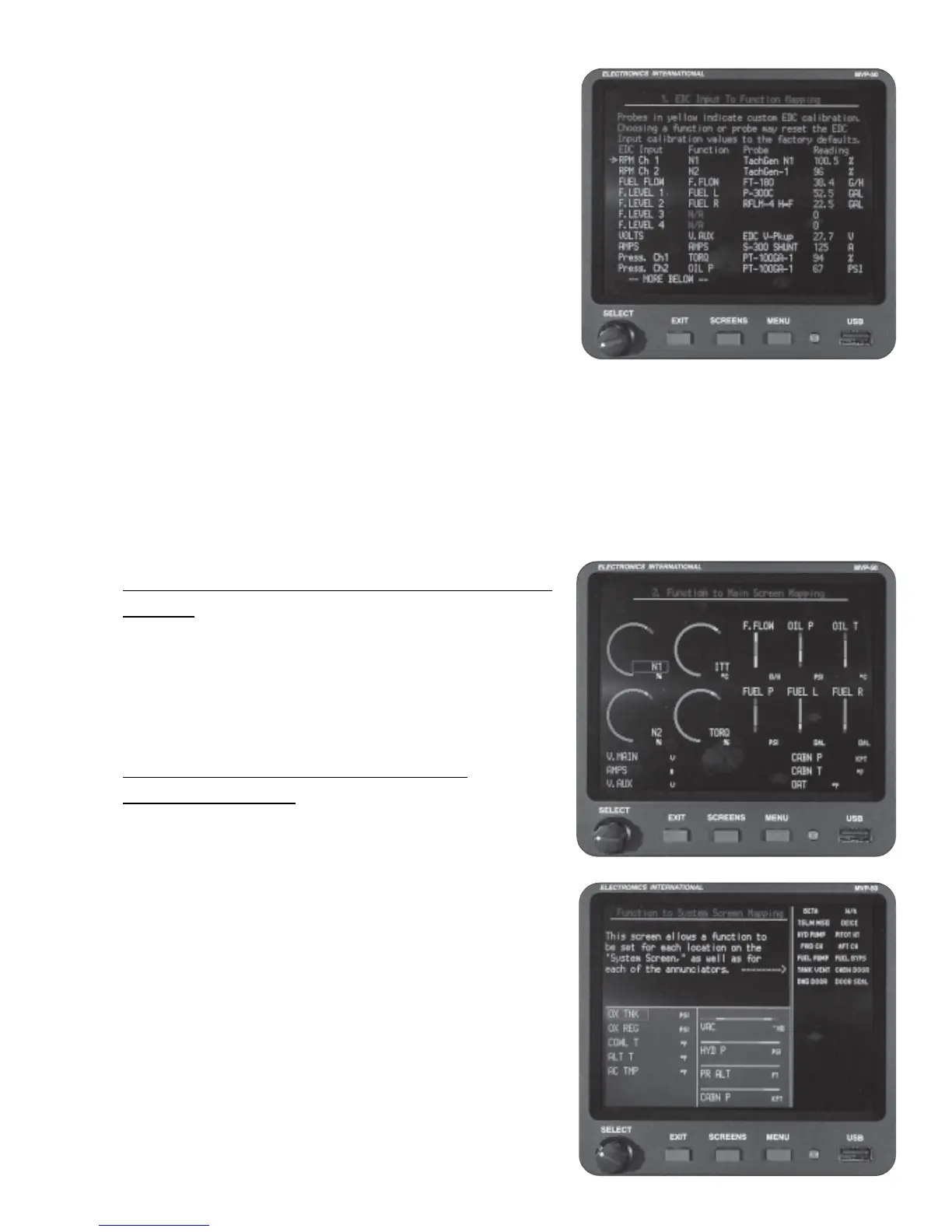

Note: Any one “Function” can only be assigned to a single

“EDC Input.” To change a Function on one EDC Input to

another EDC Input, first set the Function to “N/A” and then

reassign the Function to the new EDC Input. Functions

appear in alphabetical order. “N/A” appears before “A” and

after “Z.”

The “Reading” column at the far right of the screen shows the

current reading for each EDC Input. This can be used to

troubleshooting a channel (e.g., you can heat a temperature

probe or apply pressure to a pressure transducer and see

which EDC Input responds).

If a probe listed in the “Probe” column is shown in yellow, the

calibration of the EDC Input for that probe has been changed

from factory default. EDC Input calibration can only be changed in screen #5. Changing the calibration for an

EDC Input is for advanced users and normally is not recommended.

The EDC fuel level, pressure and temperature inputs can be configured for many different functions using

standard and/or custom probes. To calibrate an EDC Input to a custom probe, see the “5. EDC Input

Calibration Screen” section in this manual.

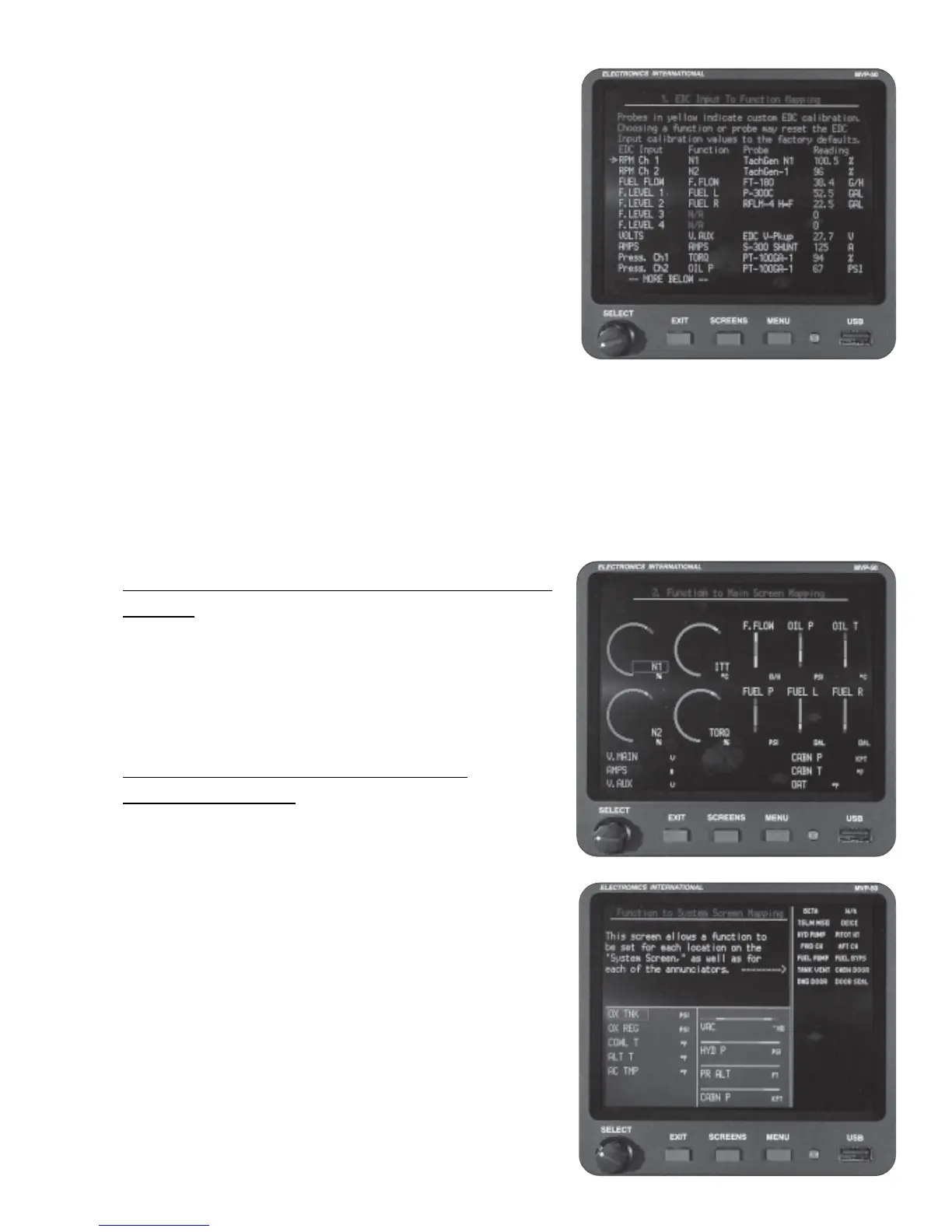

6.3.2 “2. Function to Main Screen Mapping”

Screen:

This screen allows you to customize the Main Engine Screen

by mapping functions into any of the four arc gauges, six

vertical gauges or six digital gauges.

6.3.3 “3. Function to System Screen

Mapping” Screen:

This screen allows you to customize the System Screen by

mapping a Function (that has been defined in the “1. EDC

Input to Function Mapping” screen) into any one of the seven

Digital gauges on the left side of this screen or any one of the

four Horizontal Strip gauges located on the right side of this

screen.

Also, annunciators may be mapped into the right portion of

this screen. The annunciators mapped into the left column

(top to bottom) of this screen will show in the top row (left to

right) on the Main Engine Screen. The annunciators mapped

into the right column (top to bottom) of this screen will show

in the second row (left to right) on the Main Engine Screen.

34

Loading...

Loading...