1

WSG-1068 GENERAL INFORMATION

Compression Tests

Compression Gauge Check

1. Make sure the oil in the crankcase is of the

correct viscosity and at the proper level and that

the battery is properly charged. Operate until

the engine is at normal operating temperature.

Turn the ignition switch to the OFF position,

then remove all the spark plugs.

2. Set the throttle plates in the wide-open position.

3. Install a Compression Tester in the No. 1

cylinder.

4. Install an auxiliary starter switch in the starting

circuit. With the ignition switch in the OFF

position, and using the auxiliary starter switch,

crank the engine a minimum of five compression

strokes and record the highest reading. Note the

approximate number of compression strokes

required to obtain the highest reading.

5. Repeat the test on each cylinder, cranking the

engine approximately the same number of

compression strokes.

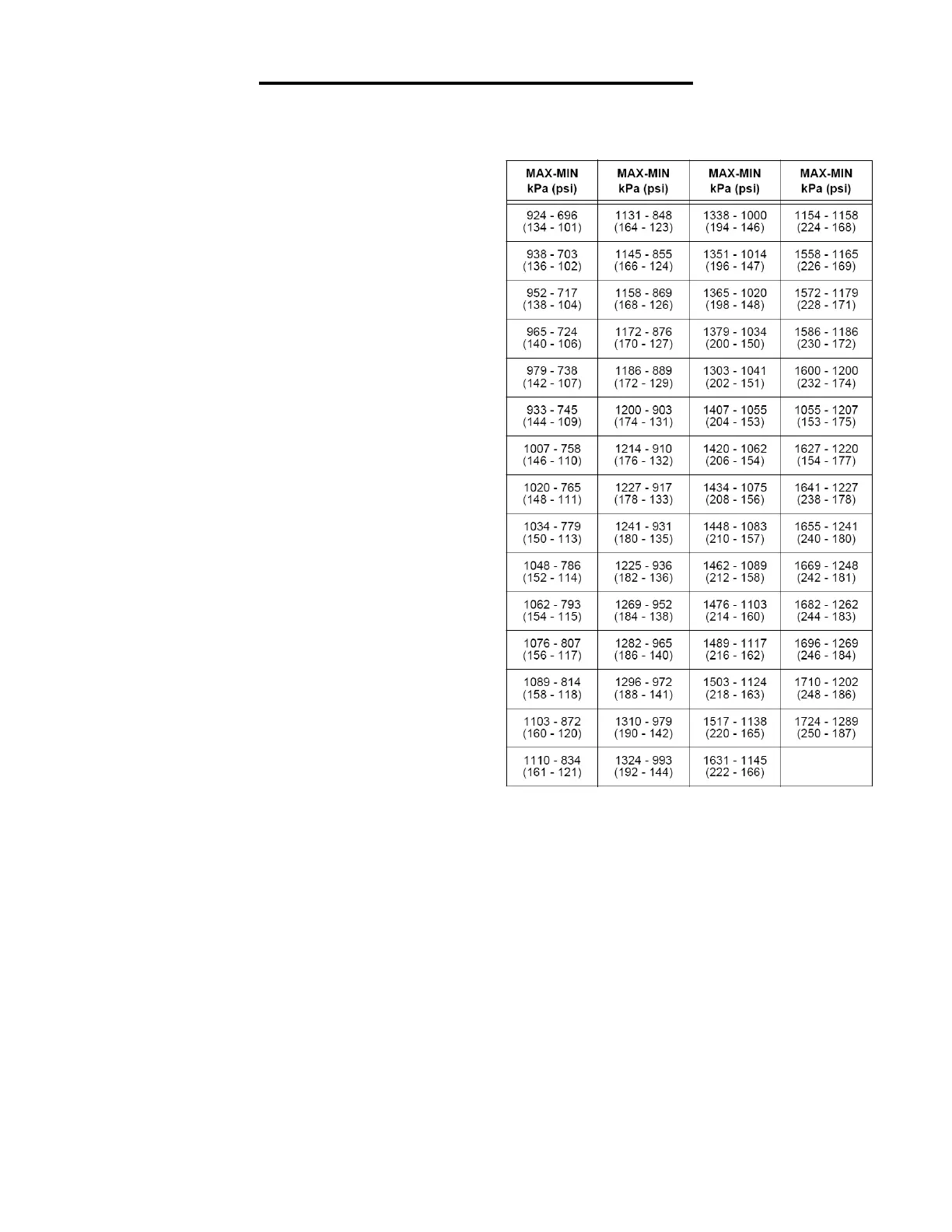

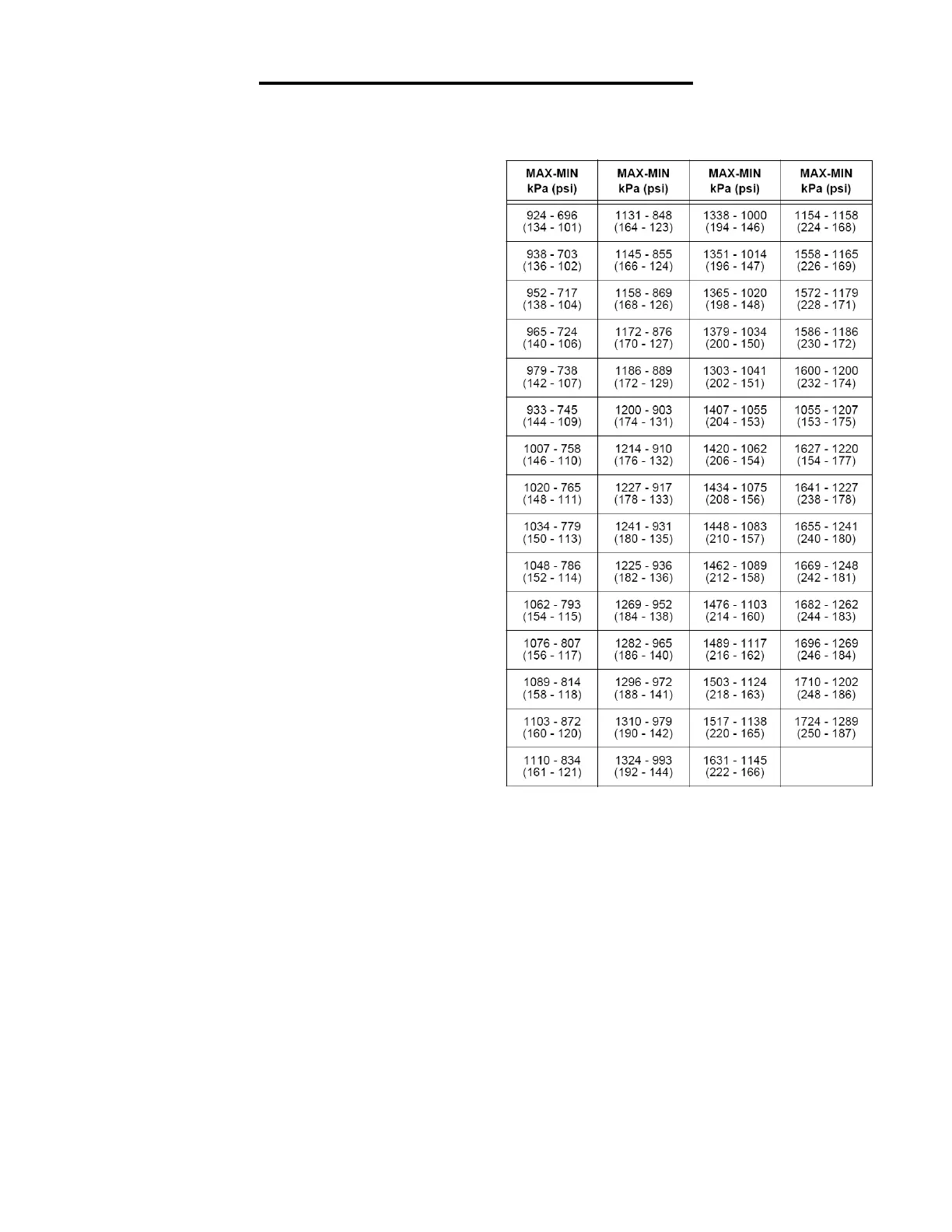

Test Results

The indicated compression pressures are considered

within specification if the lowest reading cylinder is

within 75 percent of the highest reading. Refer to the

Compression Pressure Limit Chart.

If one or more cylinders reads low, squirt approximately

one tablespoon of clean engine oil meeting Ford

specification ESE-M2C153-E on top of the pistons in

the low-reading cylinders. Repeat the compression

pressure check on these cylinders.

Compression Pressure Limit Chart

Interpreting Compression Readings

1. If compression improves considerably, with the

addition of oil, piston rings are faulty.

2. If compression does not improve with oil, valves

are sticking or seating improperly.

3. If two adjacent cylinders indicate low

compression pressures and squirting oil on

each piston does not increase compression, the

head gasket may be leaking between cylinders.

Engine oil or coolant in cylinders could result

from this condition.

Use the Compression Pressure Limit Chart when

checking cylinder compression so that the lowest

reading is within 75 percent of the highest reading.

Loading...

Loading...