8

WSG-1068 GENERAL INFORMATION

Hydraulic Lash Adjuster

Hydraulic lash adjuster noise can be caused by any of

the following:

excessive collapsed lash adjuster gap

sticking lash adjuster plunger

lash adjuster check valve not functioning

properly

air in lubrication system

leakdown rate too rapid

excessive valve guide wear

Excessive collapsed lash adjuster gap can be caused

by loose rocker arm seat bolts/nuts, incorrect initial

adjustment or wear of lash adjuster face, or worn roller

lash adjusters, push rod, rocker arm, rocker arm seat or

valve tip. With lash adjuster collapsed, check gap

between the valve tip and the rocker arm to determine if

any other valve train parts are damaged, worn or out of

adjustment.

A sticking lash adjuster plunger can be caused by dirt,

chips or varnish inside the lash adjuster.

A lash adjuster check valve that is not functioning can

be caused by an obstruction such as dirt or chips that

prevent it from closing when the camshaft lobe is lifting

the lash adjuster. It may also be caused by a broken

check valve spring.

Air bubbles in the lubrication system will prevent the

lash adjuster from supporting the valve spring load. This

can be caused by too high or too low an oil level in the

oil pan or by air being drawn into the system through a

hole, crack or leaking gasket on the oil pump screen

cover and tube.

If the leakdown time is below the specified time for used

lash adjusters, noisy operation can result. If no other

cause for noisy lash adjusters can be found, the

leakdown rate should be checked and any lash

adjusters outside the specification should be replaced.

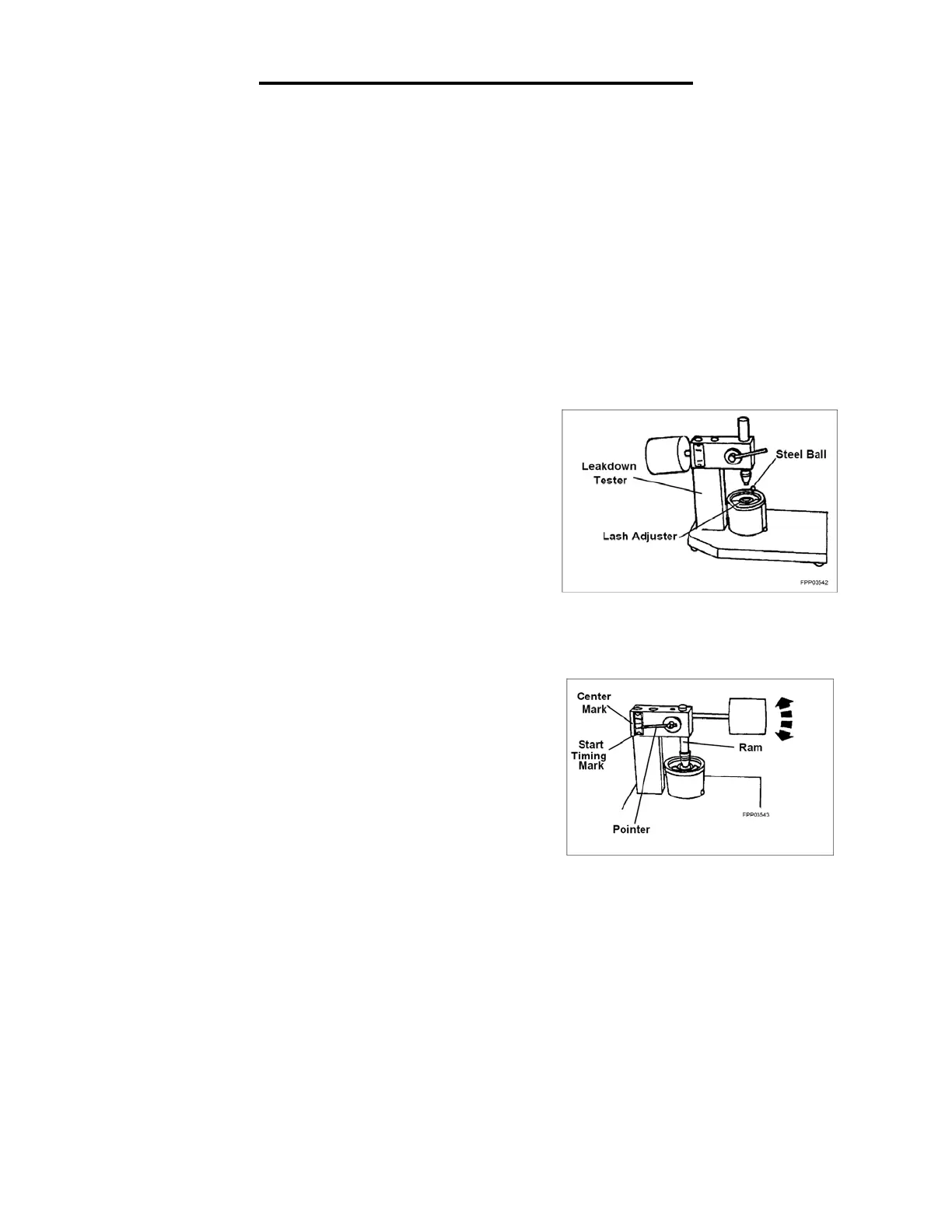

Assembled lash adjusters can be tested with Hydraulic

lash adjuster Leakdown Tester to check the leakdown

rate. The leakdown rate specification is the time in

seconds for the plunger to move a specified distance

while under a 22.7 kg (50 lb.) load. Test the lash

adjusters as follows:

Leakdown Testing

NOTE: Do not mix parts from different hydraulic valve

tappets/lash adjusters. Parts are select-fit and are not

interchangeable.

1. Clean the lash adjuster to remove all traces of

engine oil.

NOTE: lash adjusters/lash adjuster cannot be checked

with engine oil in them. Use only testing fluid. New

hydraulic lash adjusters/lash adjusters are already filled

with testing fluid.

2. Place the lash adjuster in the tester with the

plunger facing upward. Position the steel ball

provided in the plunger cap. Add testing fluid to

cover the hydraulic tappet/lash adjuster and

compress Hydraulic Tappet Leakdown Tester until

the hydraulic lash adjuster is filled with testing fluid

and all traces of air bubbles have disappeared.

The fluid can be purchased from

the tester’s manufacturer. Using kerosene or

any other fluid will not provide an accurate test.

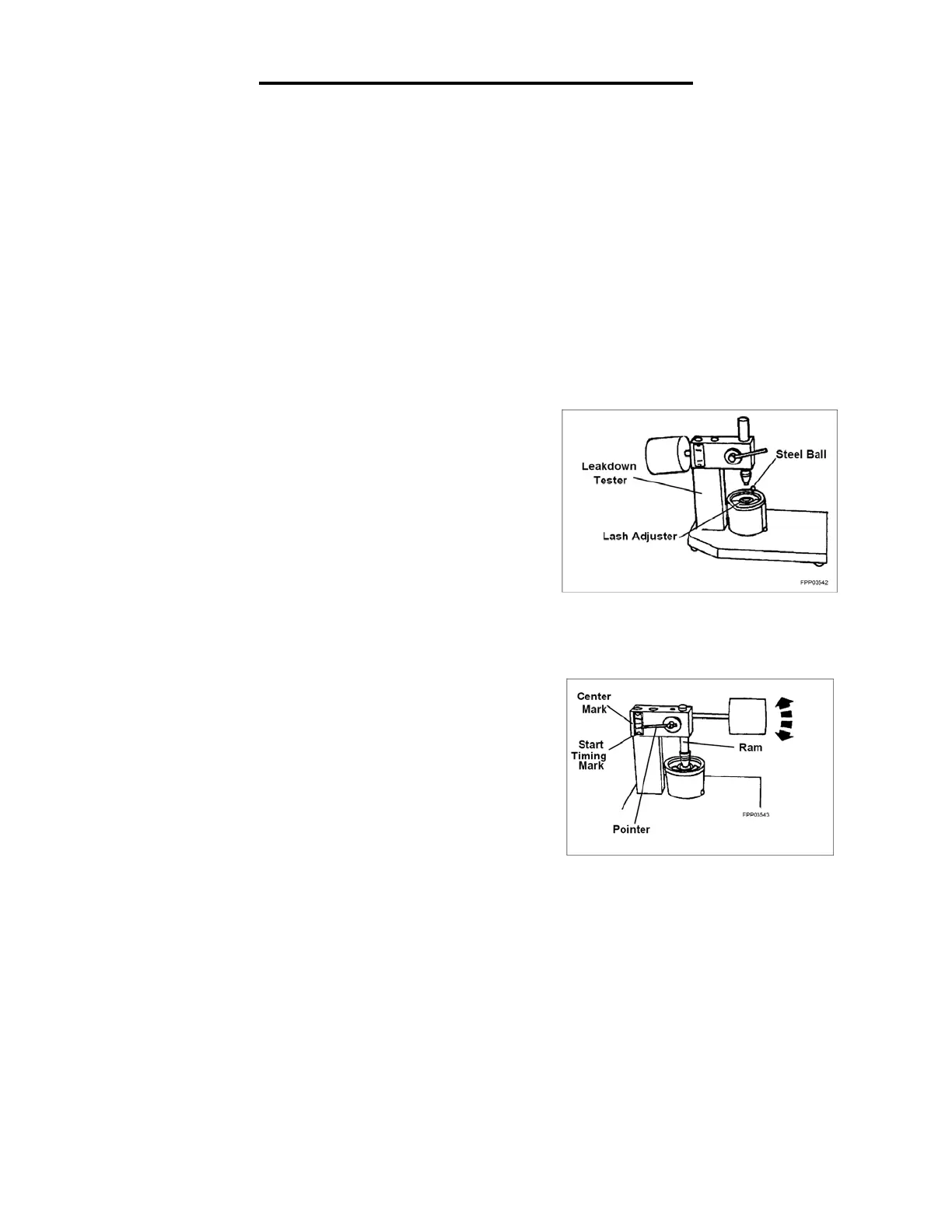

3. Adjust the length of the ram so the pointer is just

below the start timing mark when the ram contacts

the hydraulic lash adjuster. Start Timing as the pointer

passes the start timing mark and end timing as the pointer

reaches the center mark.

4. A satisfactory lash adjuster must have a leakdown

rate (time in seconds) within specified minimum

and maximum limits.

5. If the lash adjuster is not within specification,

replace it with a new lash adjuster. Do not

disassemble and clean new lash adjusters/lash

adjuster before testing because oil contained in

the new lash adjuster is test fluid.

6. Remove the fluid from the cup and bleed the fluid

from the lash adjuster by working the plunger up

and down. This step will aid in

depressing the lash

adjuster plungers when checking valve clearance.

Loading...

Loading...