13

WSG-1068 GENERAL INFORMATION

Crankshaft End Play

Special Tool(s)

1. Measure the crankshaft end play. Use the Dial

Indicator with Bracketry to measure crankshaft

end play.

2. Position the crankshaft to the rear of the cylinder

block.

3. Zero the Dial Indicator with Bracketry.

4. Move the crankshaft to the front of the cylinder

block. Note and record the camshaft end play

If camshaft end play exceeds specifications,

replace the crankshaft thrust washers or thrust

bearing.

Crankshaft Runout

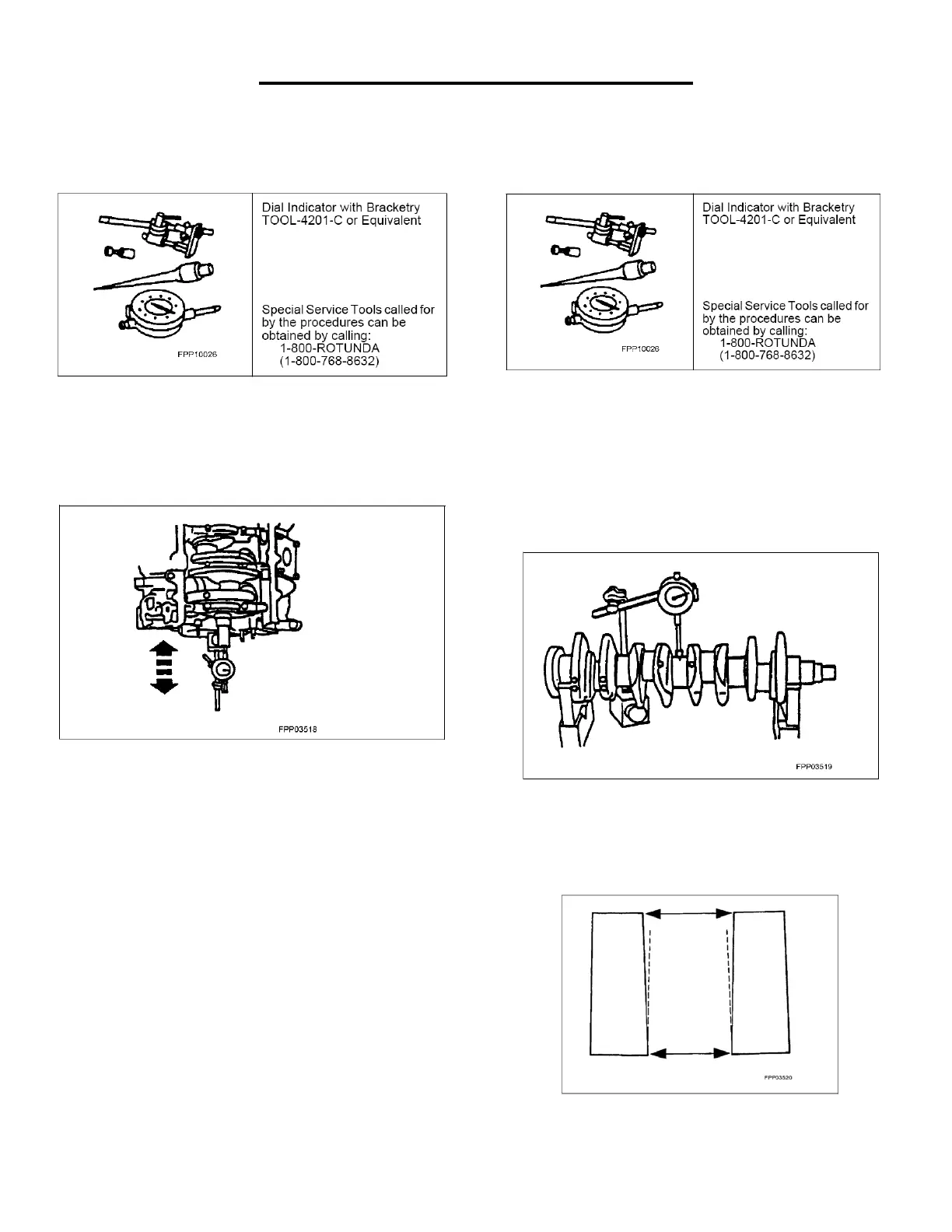

Special Tool(s)

NOTE: Crankshaft main bearing journals must be within

specifications before checking runout.

Use the Dial Indicator with Bracketry to measure the

crankshaft runout.

Rotate the crankshaft and subtract the lowest

dial indicator reading from the highest dial

indicator reading to figure the crankshaft runout.

If it is out of specification, replace as necessary.

Cylinder Bore Taper

Measure the cylinder bore at the top and bottom. Verify

the cylinder bore is within the wear limit. The difference

indicates the cylinder bore taper. Bore the cylinder to

the next oversize.

Loading...

Loading...