211

WSG-1068 COOLING SYSTEM

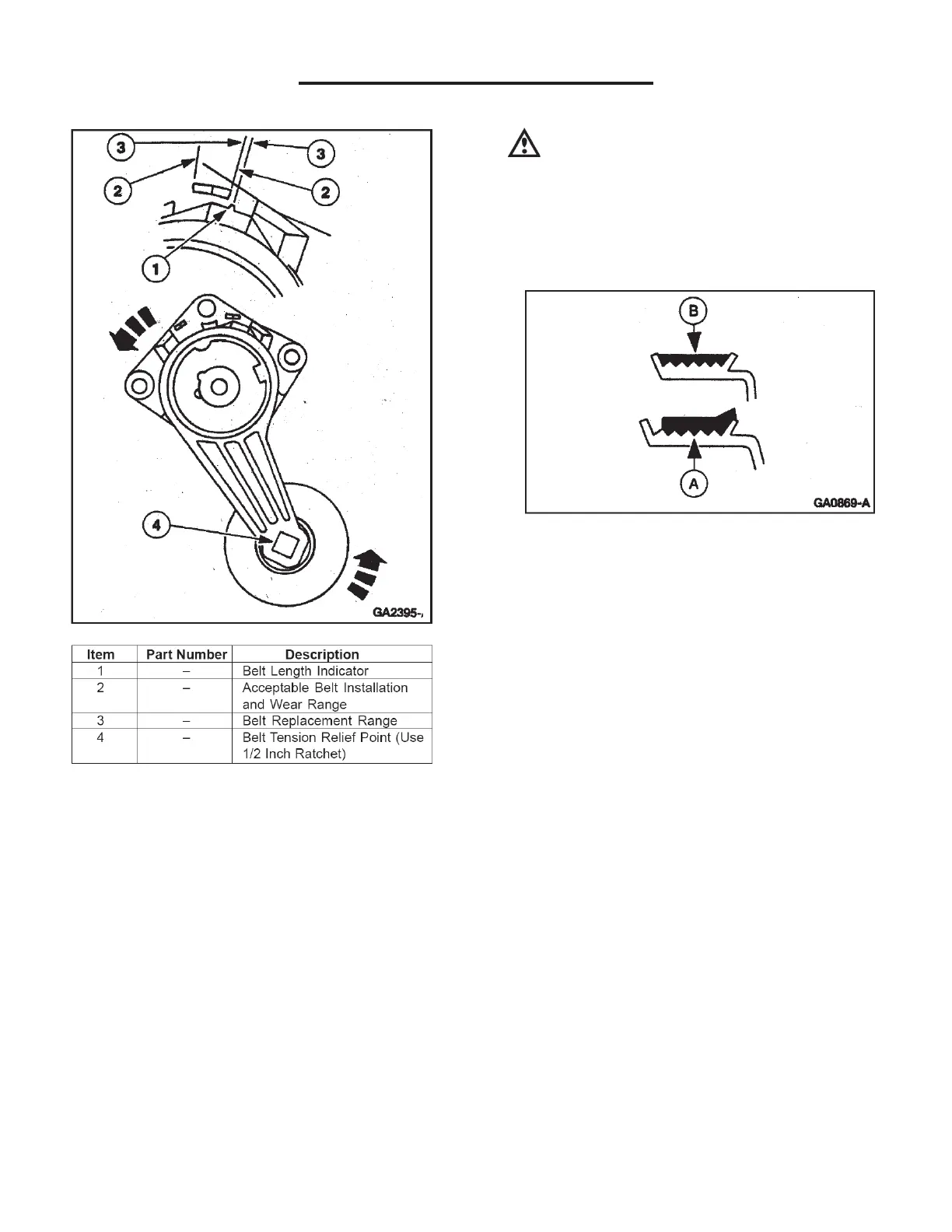

Drive Tensioner/Belt Length Indicator

Automatic tensioners are calibrated at the factory to

provide the correct amount of tension to the belt. Unless

a spring within the tensioner assembly breaks or some

other mechanical part of the tensioner fails, there is no

need to check tensioners for proper tension.

The only mechanical check that need be made, if you

have any doubt about the tensioner function, would be to

remove the belt in the area of the tensioner, to avoid belt

contact, then using the proper tool, rotate the tensioner

from its relaxed position through its full stroke and back

to the relaxed position to assure that there is no “stick,

grab, bind,” and to assure that there is tension on the

spring. It is a normal condition for the tensioner to be

moving, under certain conditions, when the engine is

running. If the tensioner meets this criteria, it should be

assumed to be a good tensioner.

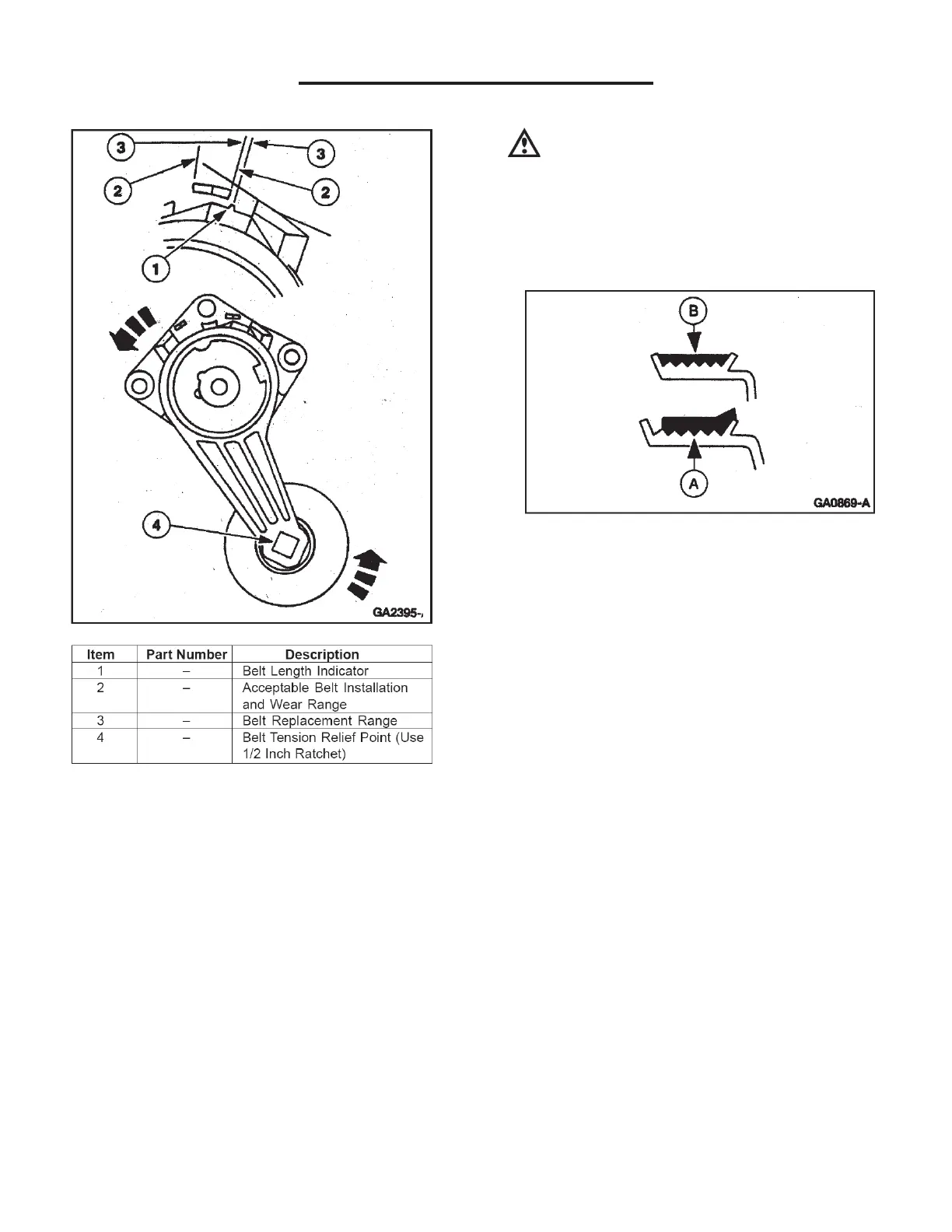

Drive Belt Misalignment

CAUTION: Incorrect drive belt installation will

cause excessive drive belt wear and may cause the

drive belt to come off the drive pulleys.

Non-standard replacement drive belts may track

differently or improperly. If a replacement drive belt

tracks improperly, replace it with an original equipment

drive belt to avoid performance failure or loss of belt.

With the engine running, check drive belt tracking. If the

A edge of the drive belt rides beyond the edge of the

pulleys, noise and premature wear may occur. Make

sure the B drive belt rides correctly on the pulley. If a

drive belt tracking condition exists, proceed with the

following:

Visually check the drive belt tensioner for damage,

especially the mounting pad surface. If the drive belt

tensioner is not installed correctly, the mounting surface

pad will be out of position. This will result in a chirp or

squeal noises.

With the engine running, visually observe the

grooves in the pulleys (not the pulley flanges or

pulley front surfaces) for excessive wobble.

Replace components as required.

Check all accessories, mounting brackets and

the drive belt tensioner for any interference that

would prevent the component from mounting

properly. Correct any interference condition and

recheck belt tracking.

Tighten all accessories, mounting brackets, and

drive belt tensioner retaining hardware to

specification.

Recheck the drive belt tracking.

Loading...

Loading...