236

WSG-1068 STARTER SYSTEM

GENERAL INFORMATION

The function of the starting system is to crank the engine

at a speed fast enough to permit the engine to start.

Heavy cables, connectors, and switches are used in the

starting system because of the large current required by

the starter while it is cranking the engine. The amount of

resistance in the starting circuit must be kept to an

absolute minimum to provide maximum current for

starter operation. A discharged or damaged battery,

loose or corroded connections, or partially broken cables

will result in slower than normal cranking speeds, and

may even prevent the starter from cranking the engine.

The starting system includes the permanent magnet

gearreduction starter motor with a solenoid-actuated

drive, the battery, a remote control starter switch (part of

the ignition switch), the starter relay, the heavy circuit

wiring, and may include starter lock-out, controlled by

the GCP through a starter lockout relay.

Field Service

Sequence Of Operation

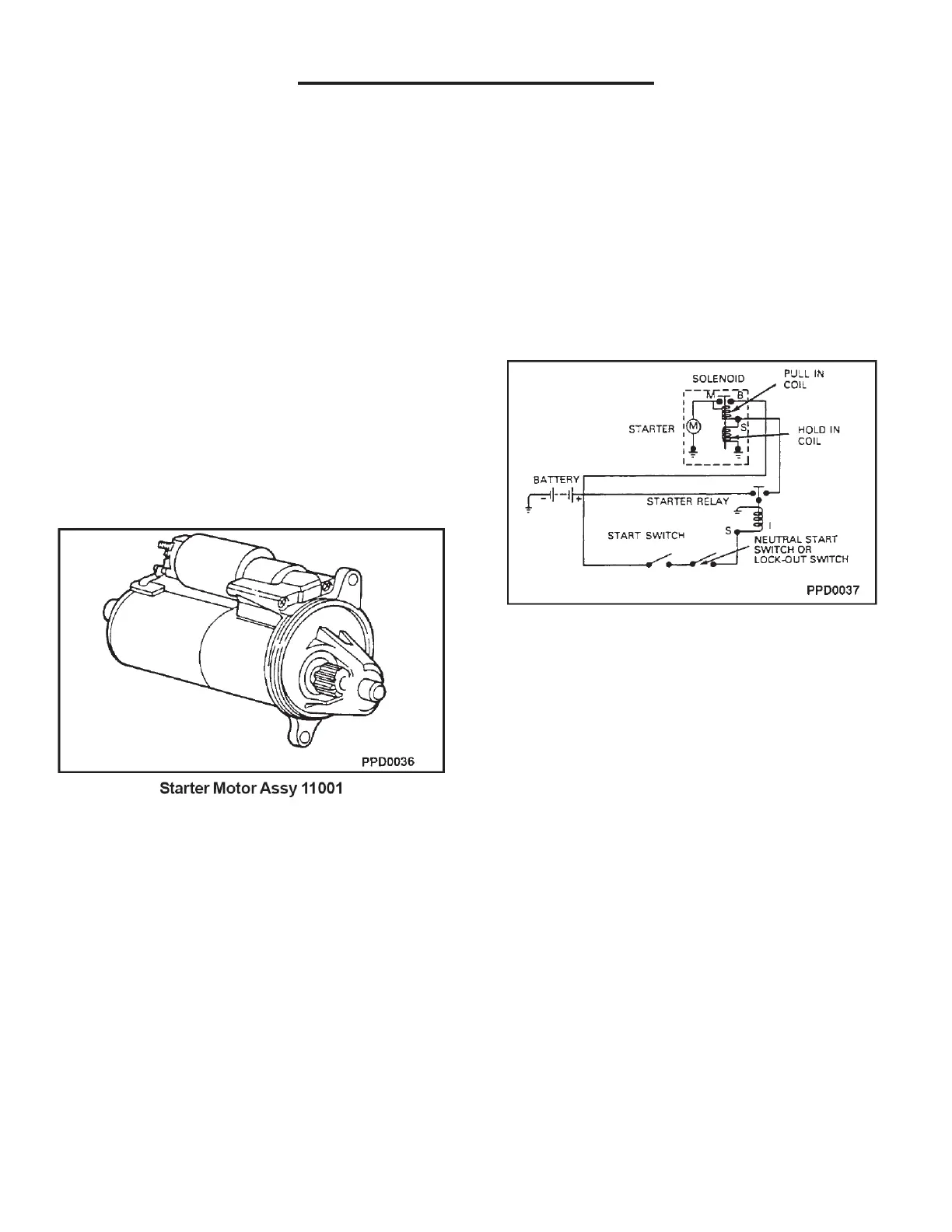

1. The ignition switch is turned to the START

position.

2. A remote starter relay is energized, which

provides voltage to the starter solenoid. The

starter solenoid is energized, creating a

magnetic field in the solenoid coil.

3. The iron plunger core is drawn into the solenoid

coil.

4. A lever connected to the drive assembly

engages the drive pinion gear to the flywheel

ring rear.

5. When the iron plunger core is all the way into

the coil, its contact disc closes the circuit

between the battery and the motor terminals.

6. The current flows to the motor, and the drive

pinion gear drives the flywheel and the engine

crankshaft.

7. As current flows to the motor, the solenoid pull in

coil is bypassed.

8. The hold-in coil keeps the drive pinion gear

engaged with the flywheel.

9. The gear remains engaged until the ignition

switch is released from the START position.

NOTE: The GCP is programmed to lock the starter out

when the engine is operating over 600 rpm and the

following sequence takes place:

Starter Lockout Relay

See page 07-6 for further details.

1. During start up with key in the on position 12V

(B+) is applied to relay PIN 72 of the GCP (Lt

Gn/ Pr).

2. With ignition switch turned to the crank position,

current flows from ignition switch to relay circuit

87A (LB/Pink) 16G through relay and out circuit

30 (LB/Pink) 16G to starter solenoid.

3. The starter than should respond as in steps 2

through 9. The GCP keeps the starter relay

closed until it reads 400+ engine rpm. Over 600

rpm the GCP grounds circuit causing the relay to

open. This will prevent starter engagement while

engine is running.

NOTE: An overrunning clutch in the drive assembly

protects the starter from the excessive speeds during

the brief period before the driver releases the ignition

switch from the START position (as the engine starts).

Loading...

Loading...