Installation 2. Installation

12 RC700 Series Rev.3

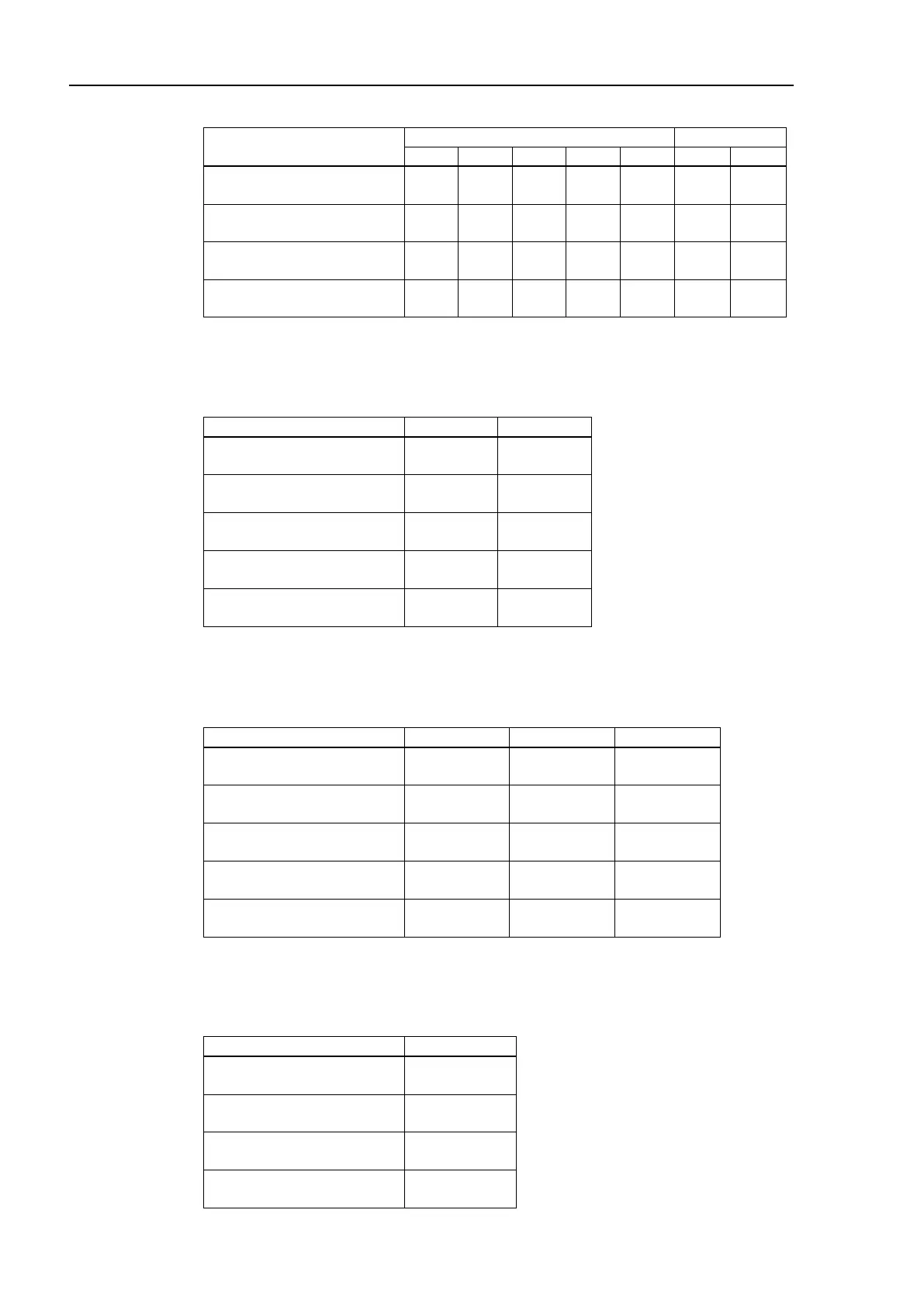

G, RS Series

Max. Reaction torque on

the horizontal plate (N·m)

100 300 500 1000 1,000 500 500

Max. Horizontal reaction

force (N)

200 2,000 2,500 4,500 7,500 1,200 1,400

Max. Vertical reaction

force (N)

300 1,000 1,500 2,000 2,000 1,100 1,100

Threaded holes for

Mounting screw

M6 M8 M8 M12 M12 M6 M6

The plate for the Manipulator mounting face should be 20 mm thick or more and made of

steel to reduce vibration. The surface roughness of the steel plate should be 25 μm or less.

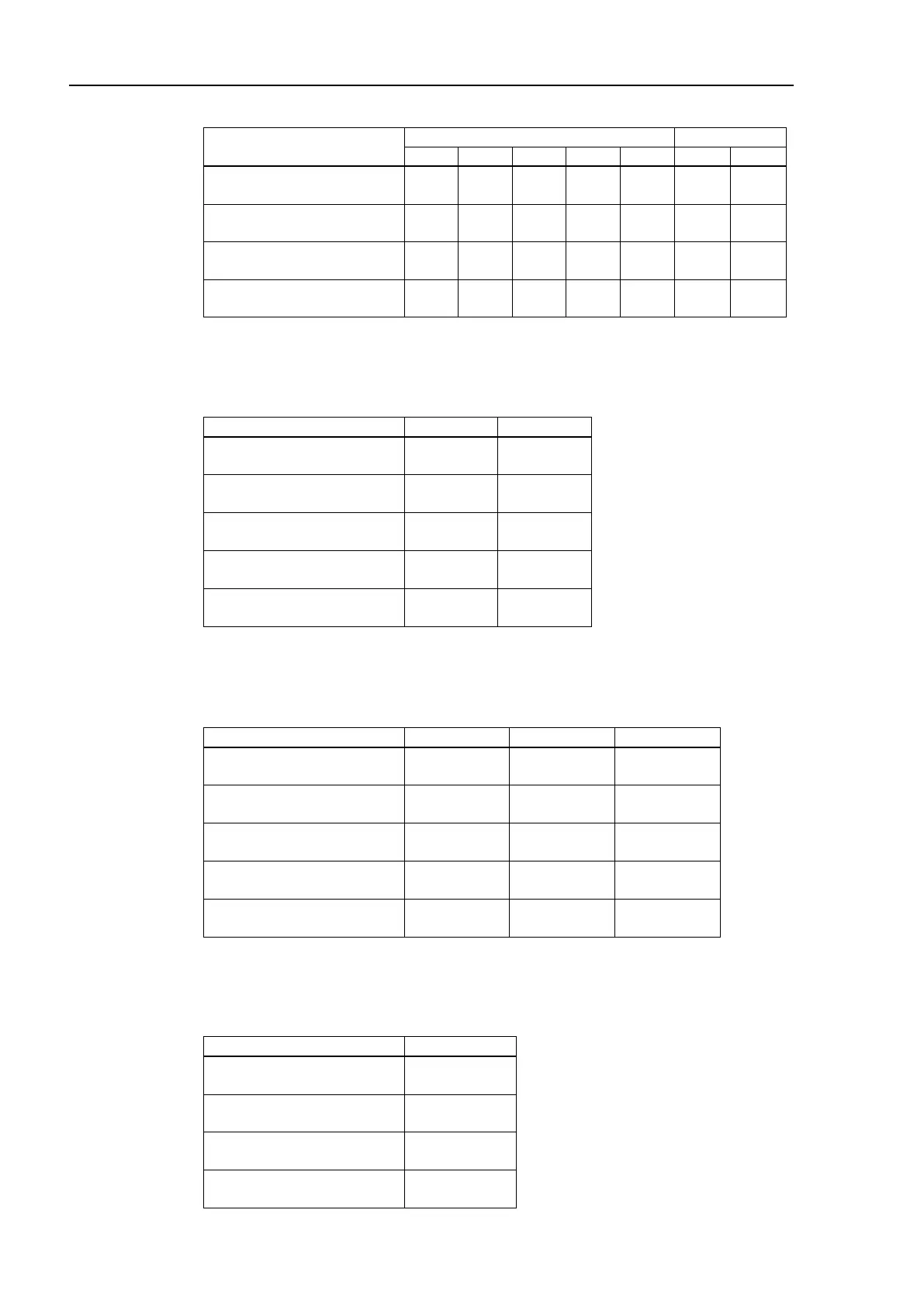

C4 Series

Max. Reaction torque on

the horizontal plate (N·m)

500 700

Max. Horizontal reaction

force (N)

800 800

Max. Vertical reaction

force (N)

600 1,000

Threaded holes for

Mounting screw

2,500 2,500

Max. Reaction torque on

the horizontal plate (N·m)

M8 M8

The plate for the Manipulator mounting face should be 30 mm thick or more and made of

steel to reduce vibration. The surface roughness of the steel plate should be 25 μm or less.

C8 Series

Max. Reaction torque on

the horizontal plate (N·m)

1,600 1,800 2,600

Max. Horizontal reaction

force (N)

1,200 1,300 1,300

Max. Vertical reaction

force (N)

1,900 2,200 3,400

Threaded holes for

Mounting screw

1,600 1,800 2,600

Max. Reaction torque on

the horizontal plate (N·m)

M12 M12 M12

The plate for the Manipulator mounting face should be 30 mm thick or more and made of

steel to reduce vibration. The surface roughness of the steel plate should be 25 μm or less.

C12 Series

Max. Reaction torque on

the horizontal plate (N·m)

2600

Max. Horizontal reaction

force (N)

1000

Max. Vertical reaction

force (N)

3400

Threaded holes for

Mounting screw

7900

Loading...

Loading...