9 CONFIGURATION MENU

0460 949 474

- 45 -

© ESAB AB 2021

The following options can be selected:

• A2TFJ1

A2 tractor automatic welding machine for Submerged Arc Welding (SAW)

• A2TGJ1

A2 tractor automatic welding machine for Gas-Shielded Metal Arc Welding (GMAW)

• A6TFF1

A6 tractor automatic welding machine for Submerged Arc Welding (SAW)

• MTW600

A6 tractor automatic welding machine for Submerged Arc Welding (SAW)

• FREE 2 AXIS

Optional configuration for connecting 2 motors to the actuator board. One for wire feed

and one for travel motion.

• FREE 3 AXIS

Optional configuration for connecting external roller beds, positioners or linear axis as

well as for 2 motors to the actuator board. One for wire feed and one for travel motion.

• N7500I

Welding head for Gouging.

• Motor Control

Optional configuration to use PEK control unit for separate motor control without a

power source.

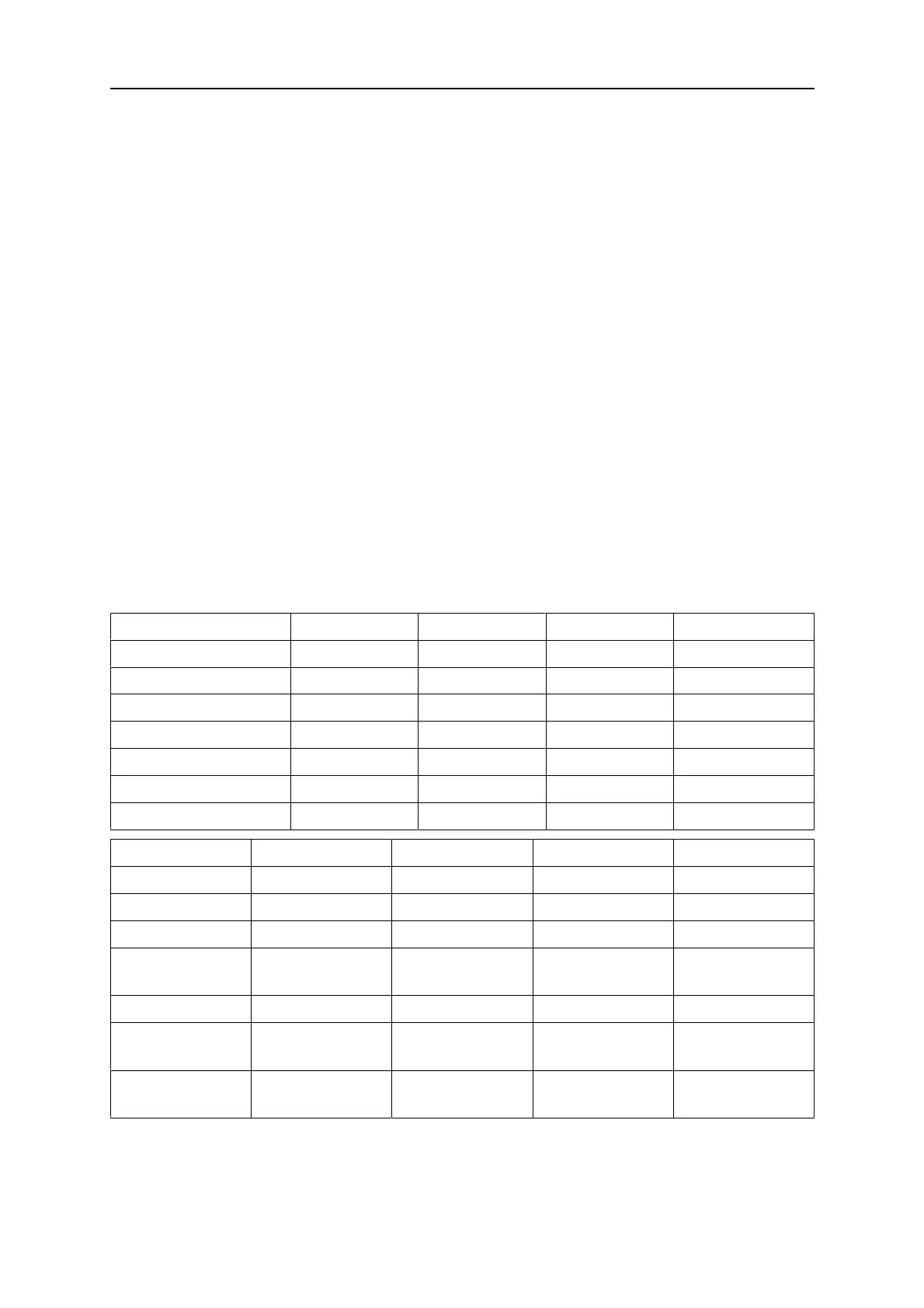

9.3.2 Wire feed axis

The wire feed motor is set automatically according to the tables below.

A2TFJ1 A2TGJ1 A6TFF1 MTW600

Motor 5035 38 RPM 5035 68 RPM VEC 4000 FHP258

Gear 1 49:1 49:1 156:1 24:1

Gear 2 1:1 1:1 1:1 1:1

Diameter feed rollers 49 mm 49 mm 49 mm 30 mm

Pulse sensor 28 ppr 28 ppr 32 ppr 28 ppr

Low manual speed 150 cm/min 150 cm/min 150 cm/min 150 cm/min

High manual speed 300 cm/min 300 cm/min 300 cm/min 300 cm/min

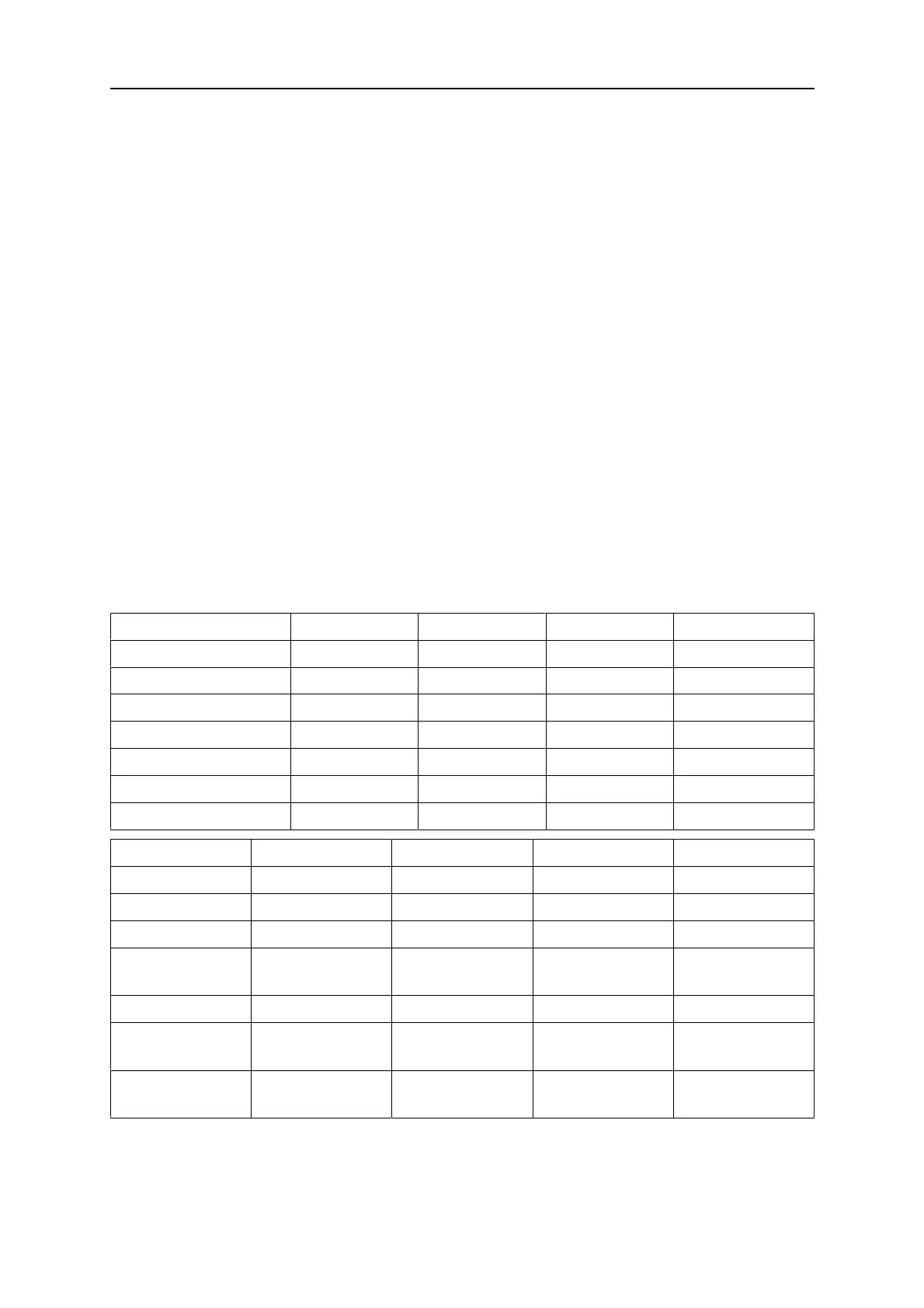

FREE 2 AXIS FREE 3 AXIS N7500I Motor Control

Motor VEC 4000 VEC 4000 N7500i 10000 VEC 4000

Gear 1 156:1 156:1 576:1 156:1

Gear 2 1:1 1:1 1:1 1:1

Diameter feed

rollers

49 mm 49 mm 40mm 49mm

Pulse sensor 32 ppr 32 ppr 128ppr 32ppr

Low manual

speed

150 cm/min 150 cm/min 61cm/min 150cm/min

High manual

speed

300 cm/min 300 cm/min 150cm/min 300cm/min

Loading...

Loading...