9 CONFIGURATION MENU

0460 949 474

- 47 -

© ESAB AB 2021

Weld diameter 1000 mm - 1000 mm

Roller diameter 1000 mm - -

When the positioner and the speed wheel are ON, the speed wheel (encoder) is at the

welding object.

When the positioner and the speed wheel are OFF, the speed wheel (encoder) is at the

motor shaft.

When the roller bed and the speed wheel are ON, the speed wheel (encoder) is at the roller

bed wheel.

When the roller bed and the speed wheel are OFF, the speed wheel (encoder) is at the motor

shaft.

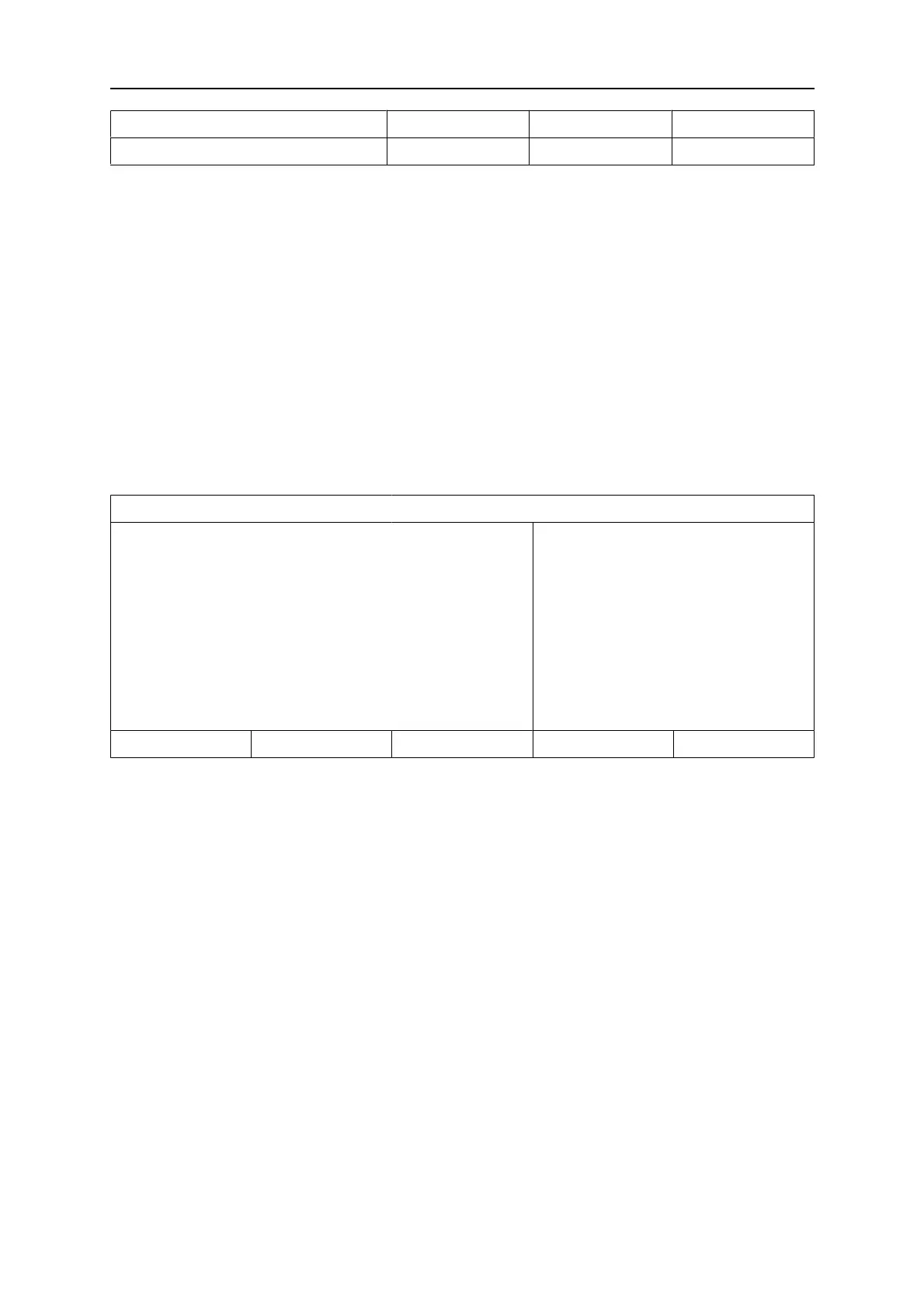

9.3.6 Tandem for LAF and TAF power sources

Used when welding with two welding heads.

Position the cursor on the TANDEM row and press ENTER. Select ON, using the positioning

knob and press ENTER.

MACHINE CONFIGURATION

PRODUCT CODE

WIRE FEED AXIS►

TRAVEL AXIS►

TANDEM►

└ WELDING HEAD

└ WELD HEAD OFFSET

└ WITH I/O

A2TF J1

ON

HEAD

20 mm

ON

QUIT

In order to weld with two welding heads, the WELD HEAD OFFSET function must be set.

WELD HEAD OFFSET is the distance in millimetres between the welding heads.

When you specify the distance between welding head 1 HEAD and welding head 2 TAIL, the

value is recalculated by the control unit to a time between when welding head 1 starts and

welding head 2 is to start.

The time that the control unit can calculate for the distance between the starting and stopping

of the welding power sources is a maximum of 65 seconds. This means that if, for example,

50 cm/min is specified, 2000 mm can be entered as the maximum WELD HEAD OFFSET.

This is so that time does not expire before welding head 2 reaches the start point.

Loading...

Loading...