5 ELECTRO SLAG WELDING

0460 949 474

- 21 -

© ESAB AB 2021

5 ELECTRO SLAG WELDING

The process is available for LAF power sources.

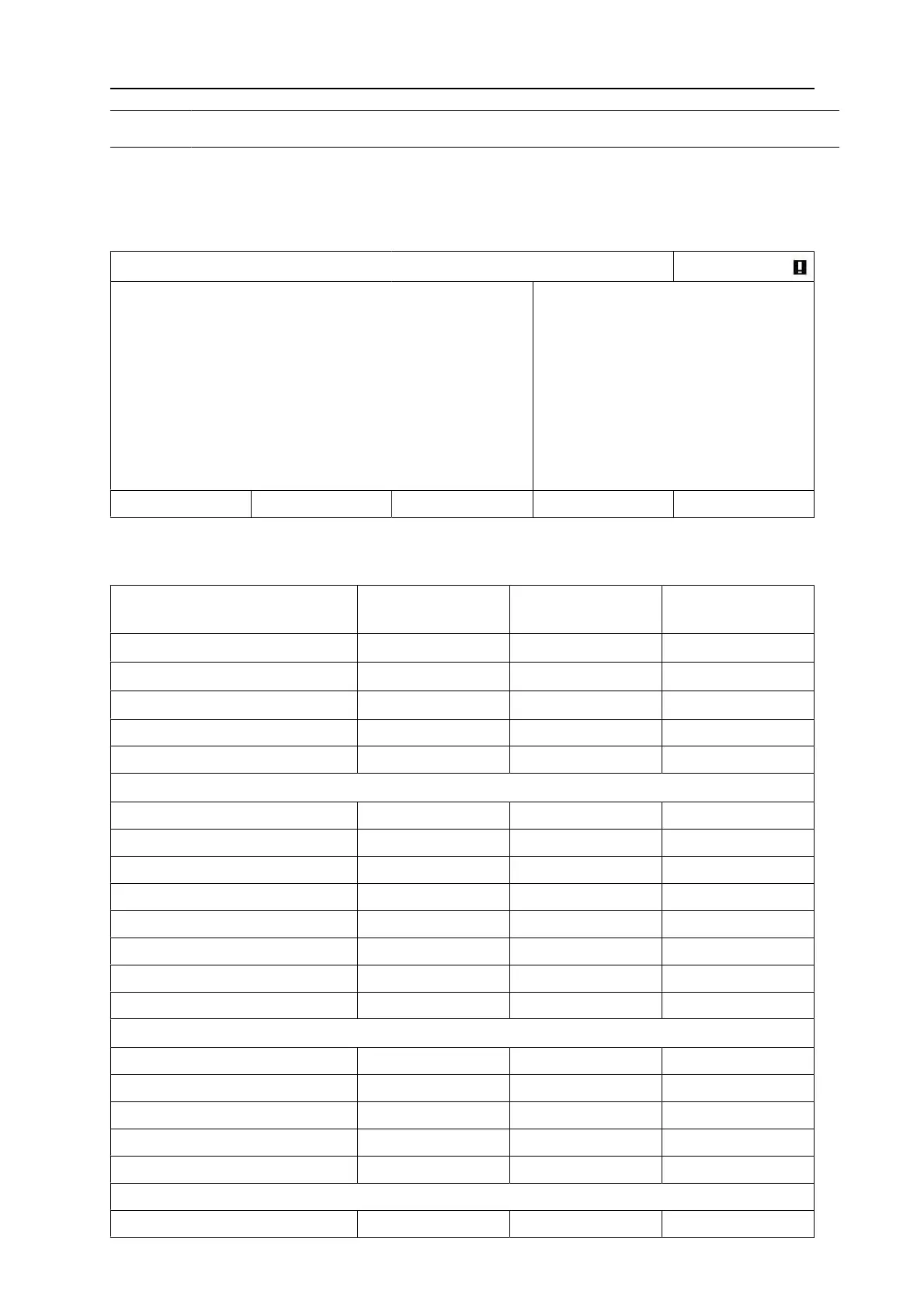

MAIN MENU » PROCESS

Electro slag welding (ESW) is a single pass welding process.

ESW

PROCESS

METHOD

REGULATION TYPE

WIRE TYPE

WIRE DIMENSION

CONFIGURATION►

TOOLS►

ESW

AC

CA

SS Strip

30×0,5 mm

SET MEASURE MEMORY FAST MODE

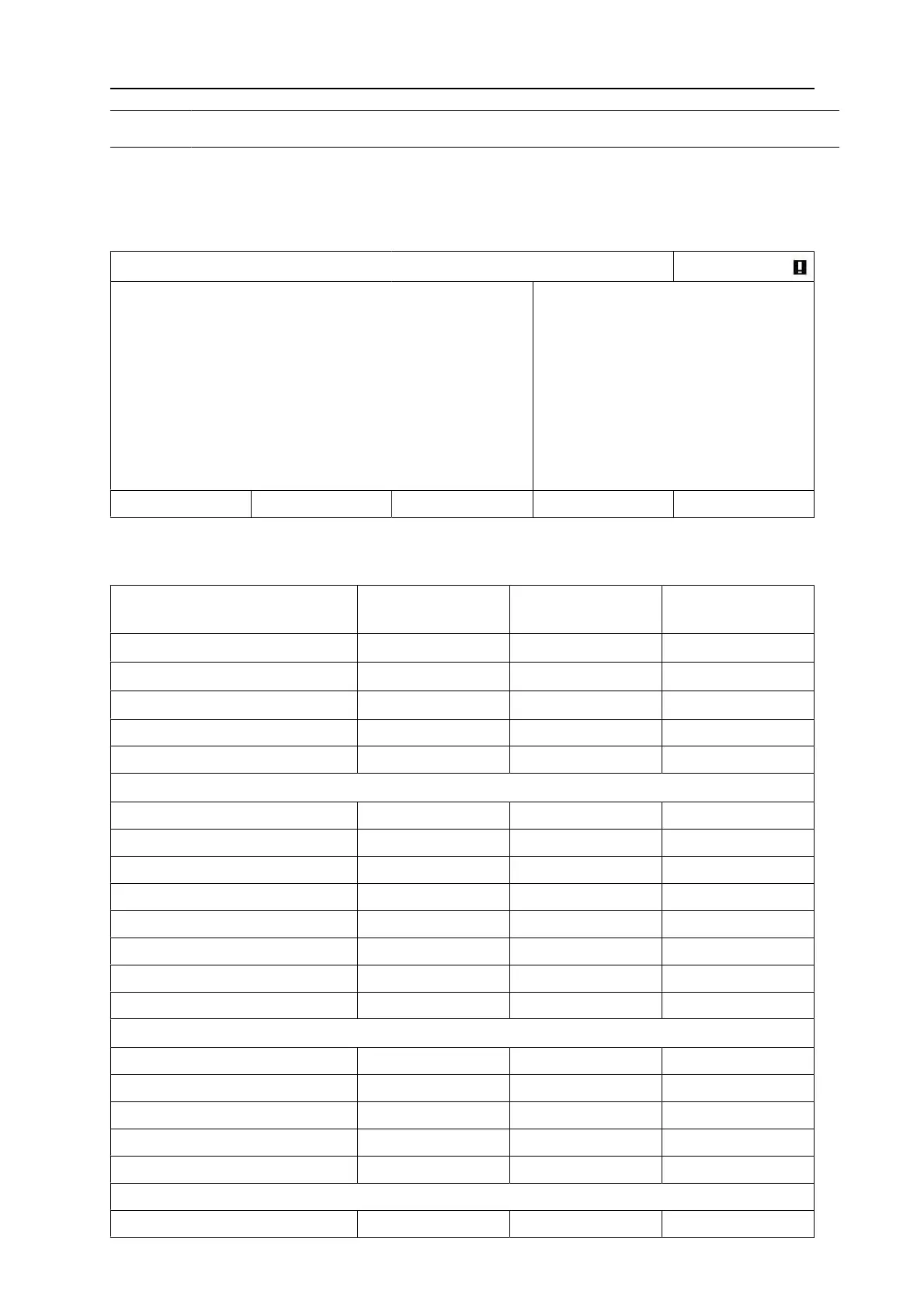

5.1 Settings for electro slag welding

Settings Setting range In steps of Value after

resetting

Arc voltage

1)

8 - 60 V 0.1 V (1V) 24 V

Welding current

1)

(CA)

0 - 3200 A 1 A 400 A

Wire feed speed

1)

(CW)

0 - 2500 cm/min 1 cm/min 300 cm/min

Travel speed * 0 - 200 cm/min 1 cm/min 30 cm/min

Welding direction ▲-■ - ■

Start data

2)

Flux pre-flow 0 - 99.0 s 0.1 s 0 s

Start adjust Min = 100% 1% 100%

Start type Direct orScratch - Direct

Wire creep start Auto orSet speed - Auto

Wire creep start speed 0 - 1000 cm/min 1 cm/min 2 cm/min

Start phases OFF orON - OFF

Open-circuit voltage OFF orON - OFF

Maximum open-circuit voltage 5 - 60 V 0.1 V 50 V

Stop data

2)

Flux post-flow 0 - 99.0 s 0.1 s 0 s

Crater filling OFF orON - OFF

Crater filling time 0 - 10 s 0.01 s 0.0 s

Burnback time 0- 10 s 0.01 s 1.50 s

Stop phases OFF orON - OFF

Control parameters

Dynamics Auto orSet values - Auto

Loading...

Loading...