ESAB FABRICATOR 141i

Manual 0-5420 4-3 BASIC WELDING GUIDE

When changing to a different electrode wire diameter, different

control settings are required. A thinner electrode wire needs

more Wirespeed to achieve the same current level.

A satisfactory weld cannot be obtained if the Wirespeed and

Voltage settings are not adjusted to suit the electrode wire

diameter and the dimensions of the work piece.

If the Wirespeed is too high for the welding voltage, “stubbing”

will occur as the wire dips into the molten pool and does not

melt. Welding in these conditions normally produces a poor

weld due to lack of fusion. If, however, the welding voltage is

too high, large drops will form on the end of the wire, causing

spatter. The correct setting of voltage and Wirespeed can be

seen in the shape of the weld deposit and heard by a smooth

regular arc sound. Refer to the Weld Guide located on the

inside of the wirefeed compartment door for setup information.

Electrode Wire Size Selection

The choice of Electrode wire size and shielding gas used

depends on the following

• Thickness of the metal to be welded

• Type of joint

• Capacity of the wire feed unit and Power Source

• The amount of penetration required

• The deposition rate required

• The bead prole desired

• The position of welding

• Cost of the wire

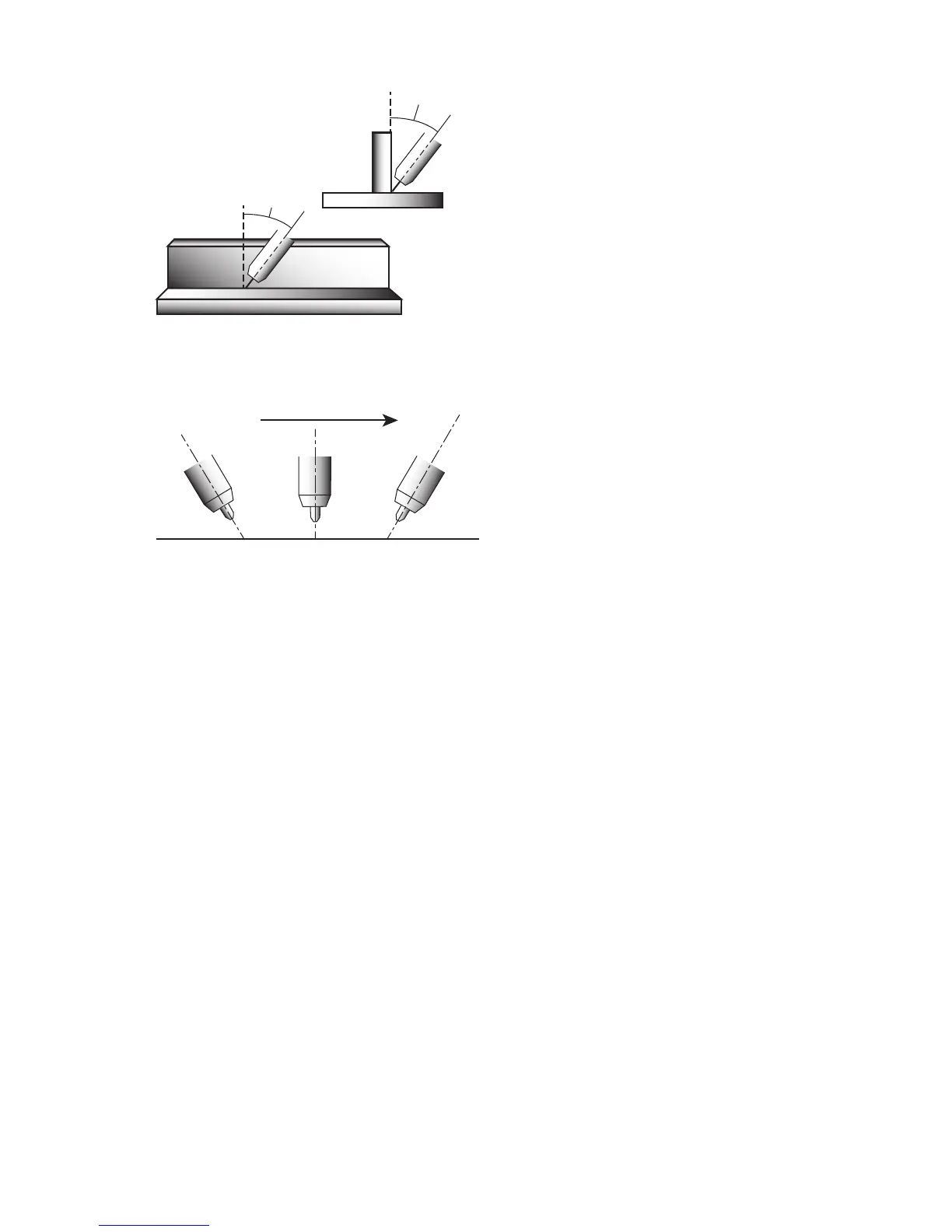

Transverse and Longitudinal

Nozzle Axes

Art # A-08998_AB

Longitudinal

Angle

Axis of Weld

Angle

Figure 4-9

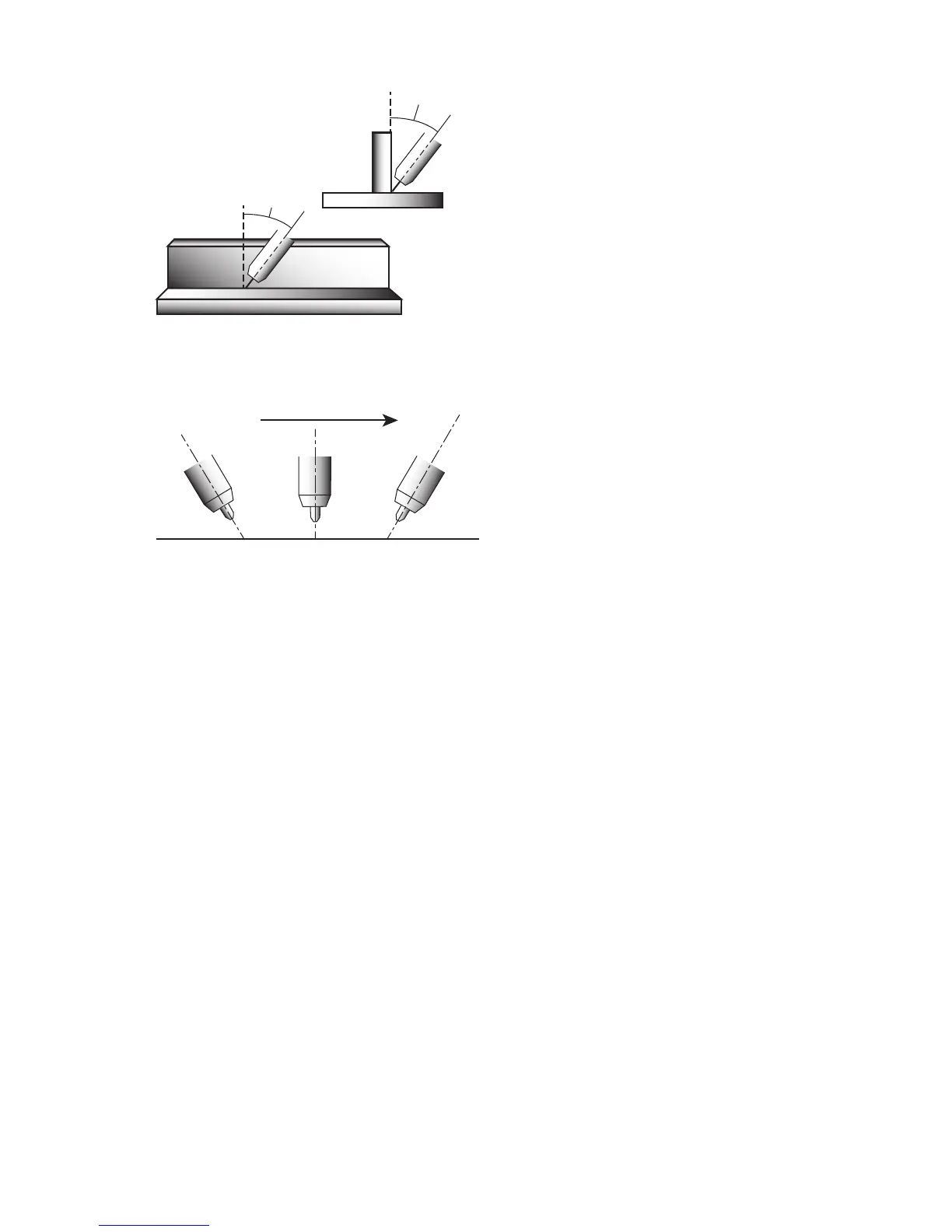

Art # A-08999_AC

Nozzle Angle, Right Handed Operator

Leading or “Pushing”

Angle

(Forward Pointing)

Trailing or “Pulling”

Angle

(Backward Pointing)

90°

Figure 4-10

Establishing the Arc and Making Weld Beads

Before attempting to weld on a finished piece of work, it is

recommended that practice welds be made on a sample metal

of the same material as that of the finished piece.

The easiest welding procedure for the beginner to experiment

with MIG welding is the flat position. The equipment is capable

of flat, vertical and overhead positions.

For practicing MIG welding, secure some pieces of 16 ga.

(1.6mm) or 1/8" (3.2mm) mild steel plate 6” (150mm) x 6”

(150mm). Use 0.035” (0.9mm) gas shielded steel or gasless

flux cored wire.

Setting of the Power Source

Power source and Wirefeeder setting requires some practice

by the operator, as the welding plant has two control settings

that have to balance. These are the Wirespeed control (refer

to section 3.10.3) and the welding Voltage Control (refer to

section 3.10.9). The welding current is determined by the

Wirespeed control, the current will increase with increased

Wirespeed, resulting in a shorter arc. Less wire speed will re-

duce the current and lengthen the arc. Increasing the welding

voltage hardly alters the current level, but lengthens the arc.

By decreasing the voltage, a shorter arc is obtained with a little

change in current level.

Loading...

Loading...