Part 3 SES 2000 AUTOCLAVE

Page 24 of 43 ST-SM8l

PART 3 MAINTENANCE

SPECIAL OPERATING MODES

Demonstration Mode

3.25 Demonstration mode provides a selection of the

available display messages for use at exhibitions and

for customer education in whatever language has been

selected. To enter this mode proceed as follows:

a Switch off power.

b Push and hold the 134°C and 121°C (without

drying) programme buttons and switch on power.

c Release programme buttons when messages

start to appear:

3.26 To exit the demonstration mode, switch off power

to the unit, then switch it on again.

Engineering Mode

CAUTION

Inbuilt protection by the controller is not

operational in Engineering Mode.

3.27 To enter the Engineering Mode proceed as

follows:

a Switch off power.

b Push and hold the 134°C and 121°C ‘with drying’

programme buttons (the bottom two buttons) and

switch on power.

c Release programme buttons when messages

start to appear. The messages, in order are:

8.8.8.8.8. with a continuous audible signal and all

programme selection LED’s illuminated, followed

by ‘count’, then the accumulative number of

completed cycles, then the error code (see section

3.40) for the last error stored in memory and finally

‘Engin’.

Note

In the engineering mode the display will read ‘Engin’

unless the heater is on, in which case the normal

temperature display will show.

3.28 In the Engineering Mode the programme selector

buttons and programme indicator LED’s function as

follows:

a Button 134°C (without drying). Press to check

chamber discharge valve function. If the valve is

working, the valve solenoid will be heard to click.

b Button 121°C (without drying). Press to check

water fill valve function. By opening chamber door

the water can be seen to flow into the chamber.

Note

Only one of the valves can be energised at a time.

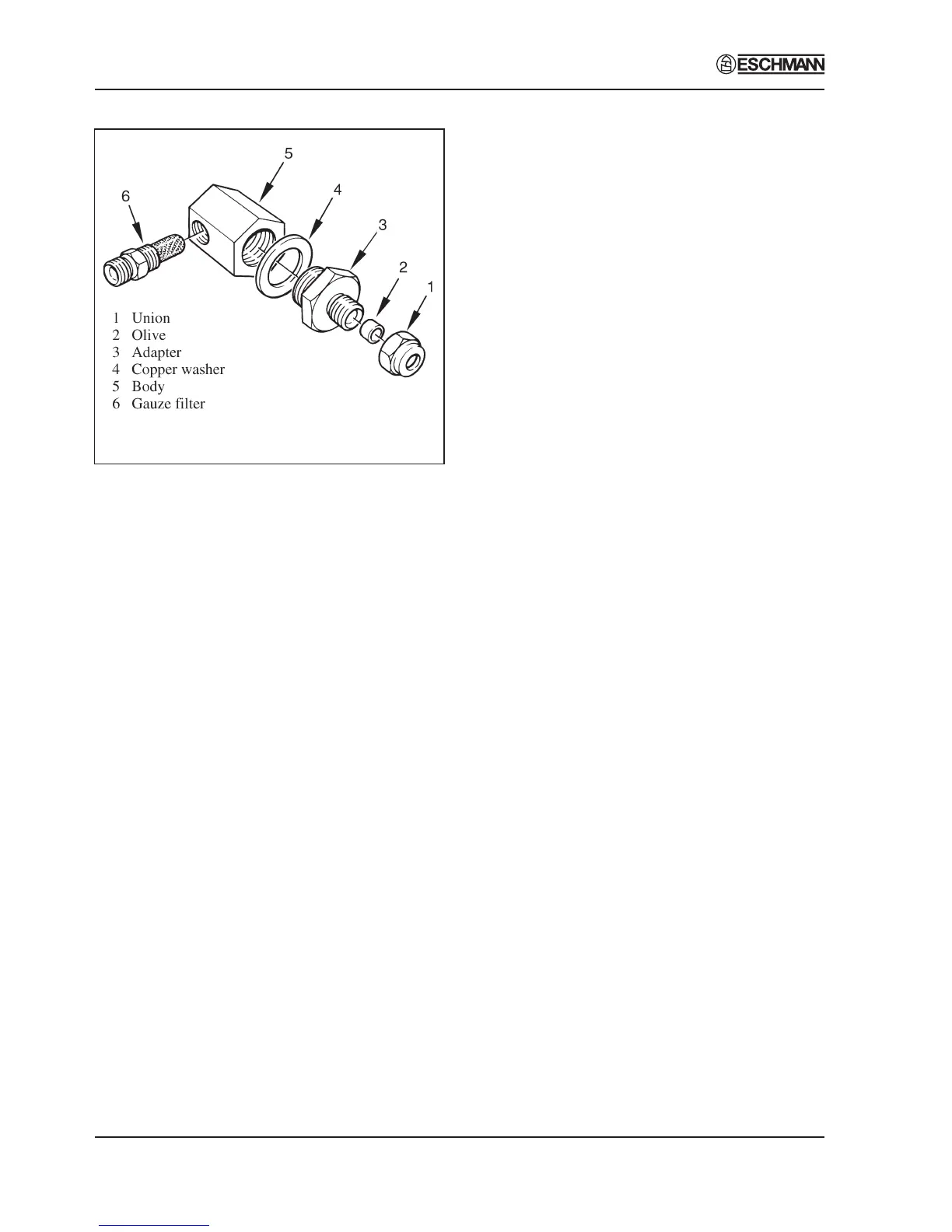

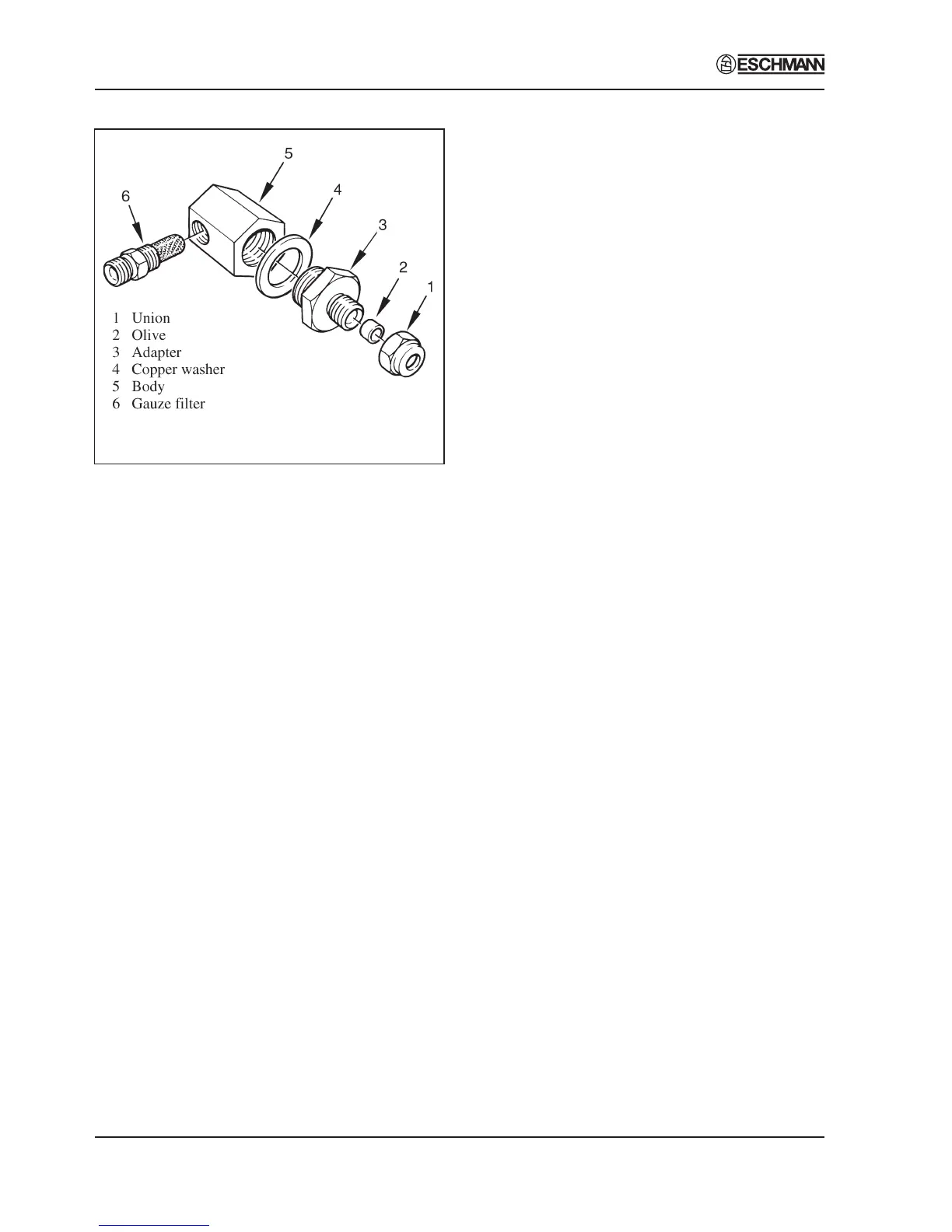

Fig. 6 Filter Unit Disassembly

Discharge Line Filter (Fig. 3 item 10 and Fig. 6)

3.23 The filter in the discharge line should be removed

and cleaned approximately every 12 months as follows:

a Ensure all water has been discharged from

chamber back into the reservoir and switch off

unit.

b Remove filter assembly from discharge line,

disassemble components and rinse clean all parts,

using distilled water only.

c Allow components to dry, then reassemble filter

unit. Ensure that copper washer is correctly

positioned with bevel side of washer against filter

body. If washer is damaged, renew it.

Printer (Fig. 2 item 22)

3.24 Remove the printer as follows:

a Disconnect all electrical connections noting their

position and orientation for correct reconnection.

b Remove two screws from the printer securing

bracket.

c Withdraw the printer through the front panel.

d Refit the printer using the reverse removal

procedure.

Loading...

Loading...