Part 3 SES 2000 AUTOCLAVE

Page 30 of 43 ST-SM8l

PART 3 MAINTENANCE

Safety Valve (Fig. 3 item 5 and Fig. 7)

3.49 Test the safety valve as follows:

CAUTION

Ensure reservoir access cover is fitted

Fig. 2 (item 16)

Note

To cancel the safety valve test, switch-off the on/off

switch for 4 seconds, then switch it on again. This will

vent all pressure and water to the reservoir.

a Refer to Routine Calibration Procedure and carry

out the instructions in section 3.48 and run the

autoclave up to 134°C.

b When 134°C is reached, switch-off power at the

power on/off switch.

c Enter the ‘Engineering Mode’ (see section 3.27).

d Switch-on the heater by pressing and holding-in

switch 4 (Fig. 7).

e With the heater switched-on, the temperature will

rise without control from the controller. The safety

valve should start to vent at approximately 138.5°C

(read from the chart recorder). The temperature

and pressure should increase until the safety

valve operates and maintains pressure below a

maximum of 2.9bar (42 p.s.i.) at 142.5°C.

Operational Test

3.50 The safety valve should be checked every 12

months for correct function and test of set pressure, full

flow and reseat pressures. Particular care should be

taken with the use of sealing compounds and PTFE

tape to ensure that they do not enter the valve.

3.51 It is recommended that adjustments, maintenance

and repair of safety valves should only be carried out by

Eschmann personnel or accredited agents. Removal

and installation of the valve is a straightforward

procedure, but on installation, wrap

PTFE tape around

the valve threaded pipe fitting.

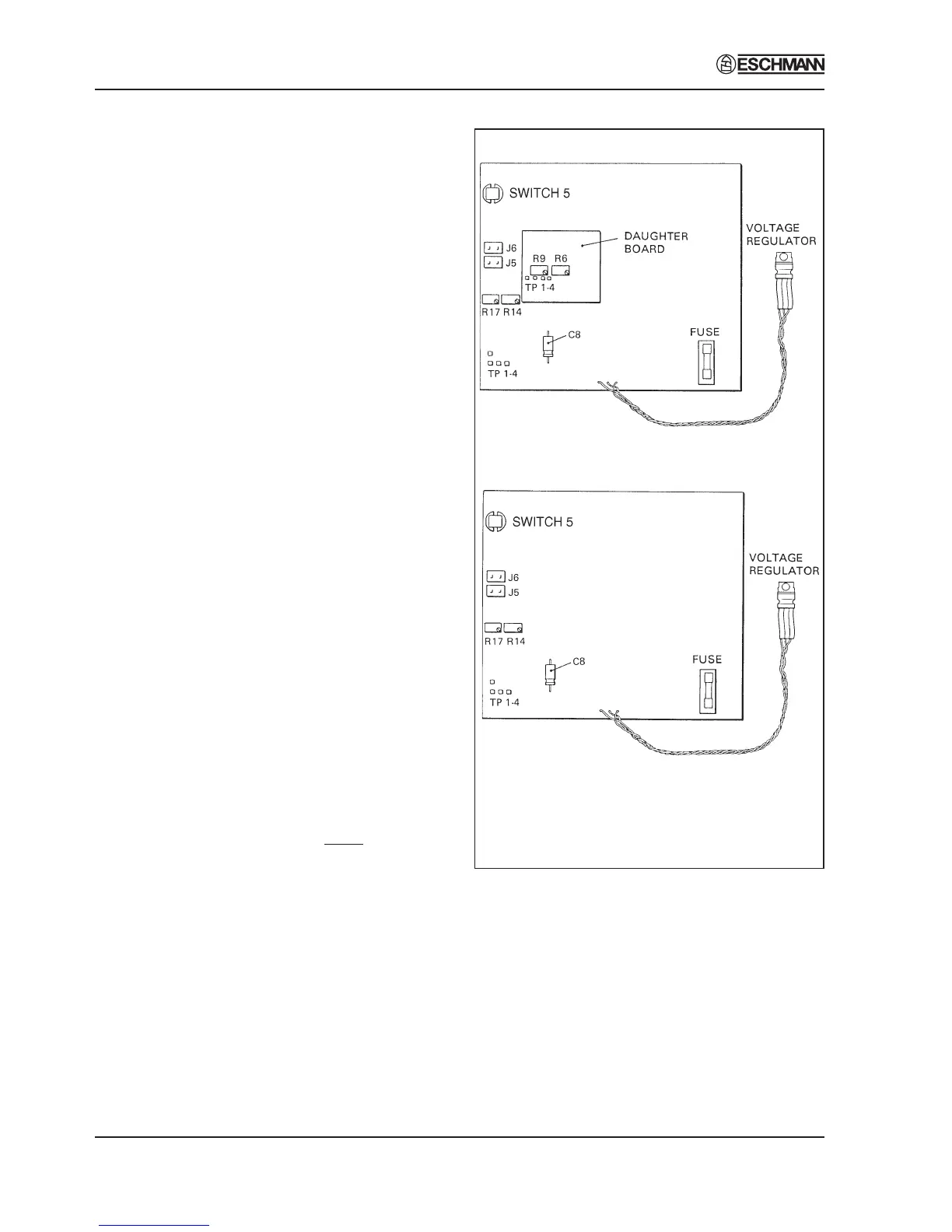

Controller Board with Daughter Board

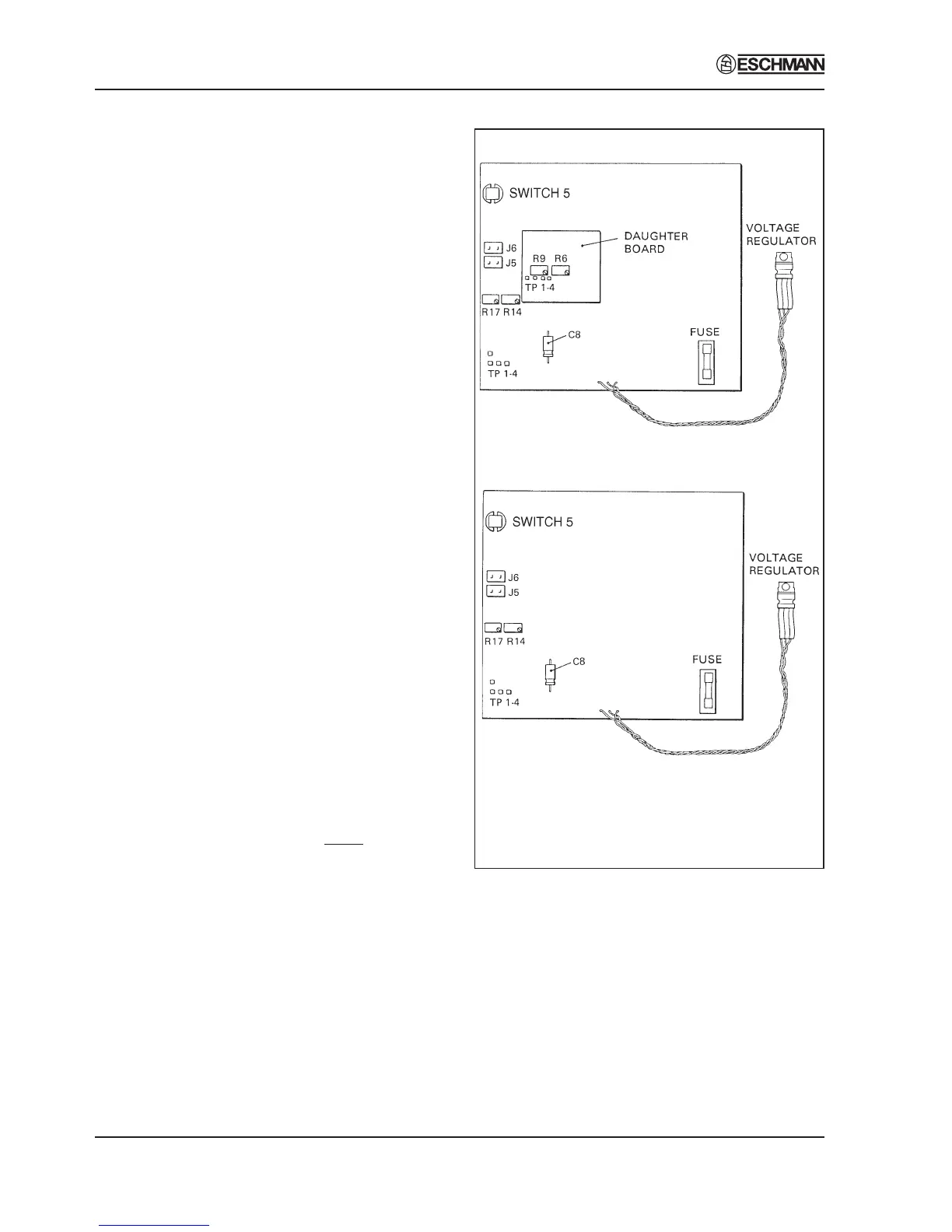

Controller Board without Daughter Board

Fig. 8 Autoclave Controller Boards

Loading...

Loading...