E-7

3.7 Operating The Machine

When the machine is set up as described in the previous pages, it is now ready to be operated. To operate

machine use the following sequence:-

1 TAIL CONVEYOR

2 MID-GRADE SIDE CONVEYOR

3 FINES CONVEYORS

4 SCREENBOX

5 FEEDER CONVEYOR

DO NOT START THESE SYSTEMS

IF THEY ARE FULL OF MATERIAL

CLEAR ANY MATERIAL AWAY

BEFORE STARTING.

NOTE:-

Engine revs are factory

preset at 2000 R.P.M. Any alterations

to these settings, to increase speed,

may lead to premature failure and

subsequent warranty loss

T

H

R

O

T

T

L

E

I

G

N

I

T

I

O

N

K

E

Y

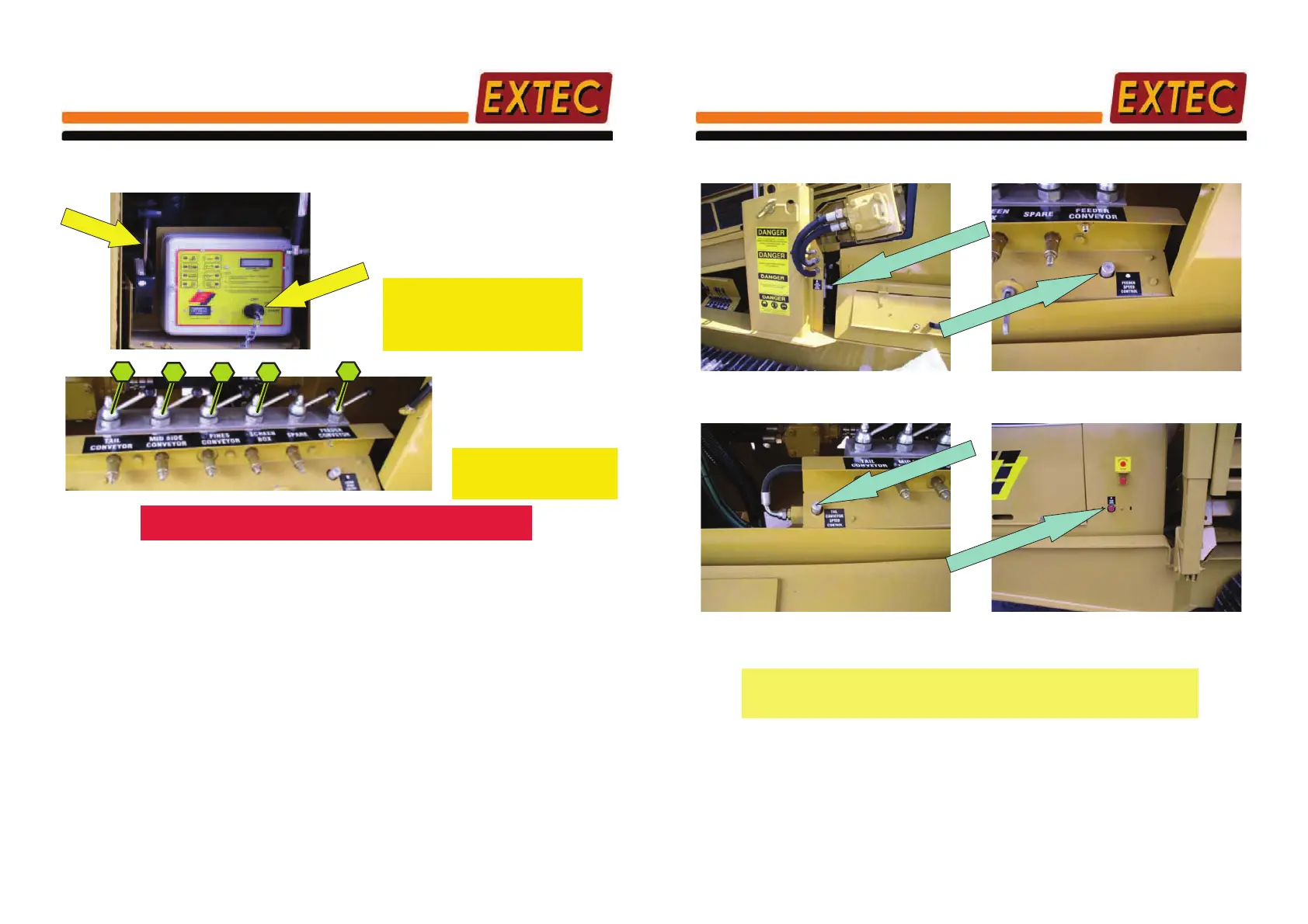

1:- Turn machine on using the

instructions set out in section 3.3

2:- Increase revs to 2000 R.P.M

using the throttle at the side of

the control box.

Prior to loading material into machine, ensure that machine is not vibrating or rocking excessively. Stabilise the

machine by relocating to more suitable ground.

LOADING MATERIAL INTO MACHINE

1. Feeder MUST be running PRIOR to feed material being placed upon it.. DO NOT start feeder if it is full of material.

2. Material which is larger than 80% of feeder discharge chute should not be presented to the feeder. STOP MACHINE and

remove any large pieces of material with the appropriate equipment. DO NOT use excavators to force any material into feeder as

any damage occurred from this action will invalidate any EXTEC warrantees.

3. Material should be fed carefully, (not dropped onto feeder) from about 300mm above feeder. Ensure that feeder is evenly

loaded over its entire length this is to help with screening fines material and to maximise production.

4. It is recommended that an excavator is used to load material into Feeder. DO NOT OVER FILL FEEDER.

5. For maximum output and minimum wear, it is recommended that the Screenbox is fed consistently with the supply of material

being steady and constant. STOP/START OPERATION OF THE FEEDER SHOULD BE AVOIDED.

6. Pressure sensors are fitted to the Hydraulic Circuit such that, if either side conveyor should become over burdened with

material or jammed, then the feeder will stop until the material is reduced to an acceptable level. If the conveyor cannot clear itself

then the material will have to be cleared manually. If so then the machine should be shut down and ignition key removed before

commencing any work on the machine.

Machine Start Sequence

1

2

3

4

5

BEFORE STARTING THE MID-GRADE SIDE CONVEYOR ENSURE THAT

THE BOTTOM SECTION IS LOCKED IN ITS LOWERED POSITION.

Section 3 Page 19

E-7

Operating The Machine

F

L

O

W

C

O

N

T

R

O

L V

A

L

V

E

F

L

O

W

C

O

N

TR

O

L

V

A

L

V

E

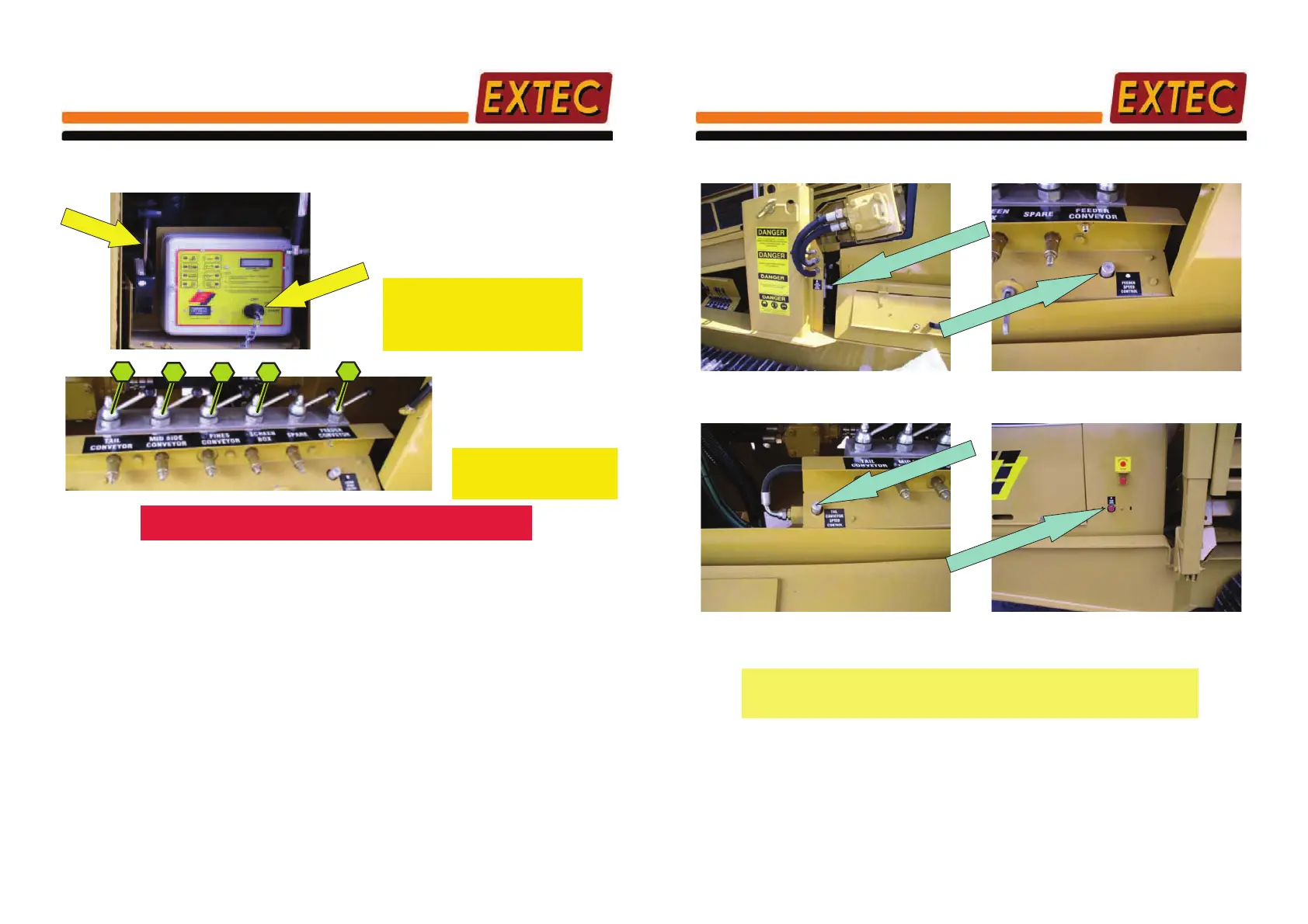

1:- Adjusting Fines Collector

Conveyor speed

2:- Adjusting Mid-Grade side

Conveyor speed

3:- Adjusting Tail Conveyor

speed

When the machine is set up as described in the previous pages, it is now ready to be

used to screen the desired material. DO NOT START SCREENING UNTIL YOU

HAVE READ AND FULLY UNDERSTOOD THIS MANUAL

F

L

O

W

C

O

N

T

R

O

L

V

A

L

V

E

3:- Adjusting Feeder Conveyor

speed

F

L

O

W

C

O

N

T

R

O

L

V

A

L

V

E

Section 3 Page 20

Loading...

Loading...