E-7

4.3 WEEKLY MACHINE MAINTENANCE

Maintenance is essential for safety and to ensure the best possible performance from your E-7 by

reducing the chances of breakdowns.

WARNING: -

The machine

MUST

be switched off and Isolated with the ignition keys removed

BEFORE making any adjustments.

DO NOT stand on any part of the engine whilst operating or carrying out any maintenance on the

machine.

All adjustments must ONLY be carried out by trained personnel.

When performing any maintenance on the machine refer to engine and feeder gearbox

manufacturers handbooks for appropriate maintenance schedules.

STOP MACHINE, ISOLATE AND REMOVE IGNITION KEY BEFORE

CARRYING OUT ANY MAINTENANCE ON THIS MACHINE.

1. Check condition of conveyor belts, rollers and other moving parts.

2. Clear any obstructions from the Screenbox.

3. Check all bolts and panels are in place and secure.

4. Clear any build up of dust from radiator using compressed air.

5. Check screen mesh for tension, and increase if necessary.

6. Check condition of service indicators on hydraulic filters, water trap and air breather

Replace if necessary.

7. Examine tail conveyor impact bars for excessive damage -Replace if necessary.

8. Check feeder pads for damage and clear any debris to ensure free movement of the

material. replace pads if necessary.

9. Check all bearings for any damage or wear. -Replace if necessary.

10. Check emergency stops are working correctly

11. Check feeder rear wing fixing bolts - tighten if necessary.

12. Check feeder gearbox oil level.

13. Inspect and adjust all belt scrapers and sealing rubbers -Replace if necessary.

Section 4 Page5

E-7

WEEKLY MACHINE MAINTENANCE

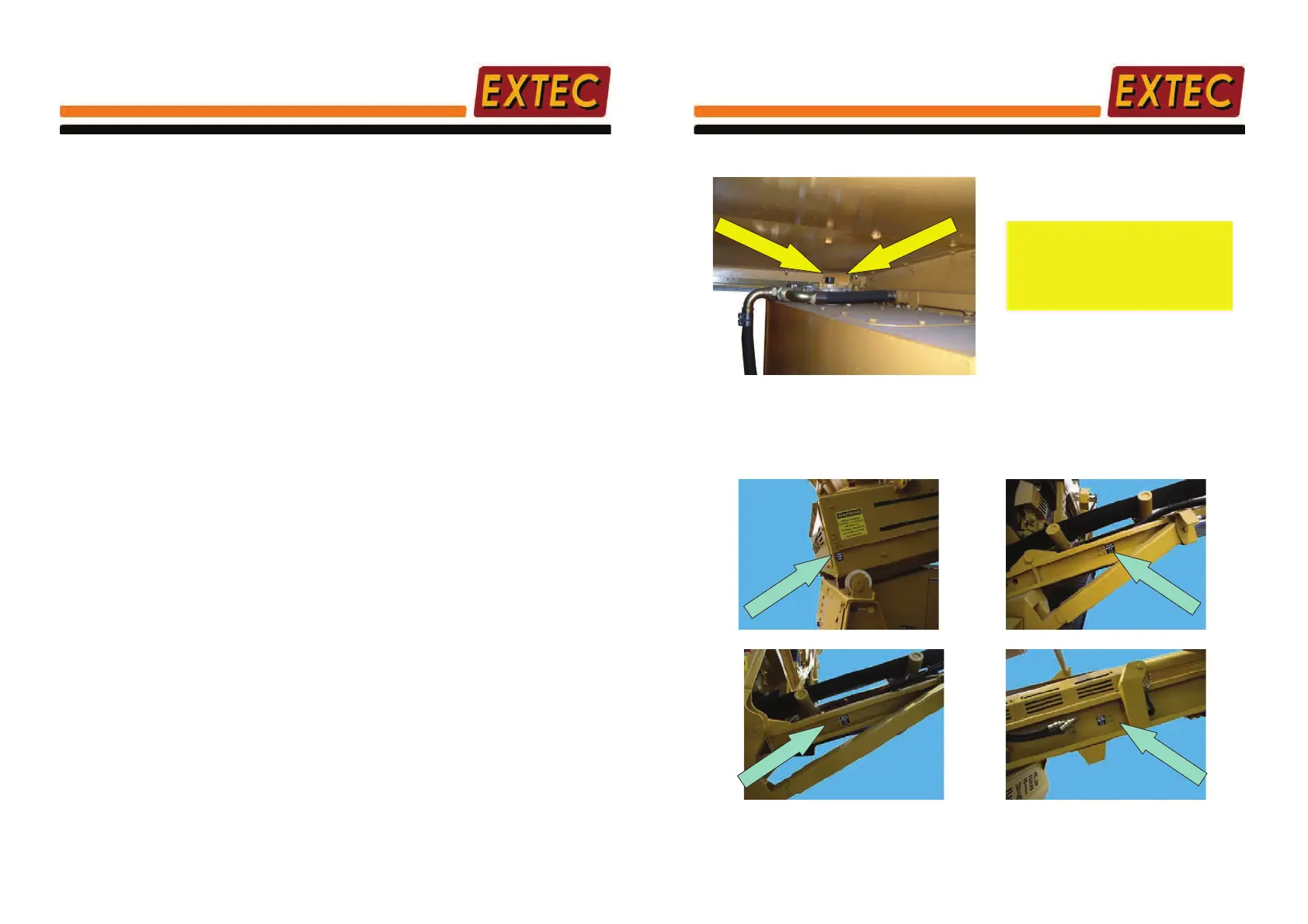

CHECKING/CHANGING HYDRAULIC TANK AIR BREATHER

Examine service indicator.

If the service indicator is green,

it is time to replace the tank air

breather. Simply remove air

breather and replace with new

one.

S

e

r

v

i

c

e

I

n

d

i

c

a

t

o

r

A

i

r

B

r

e

a

t

h

e

r

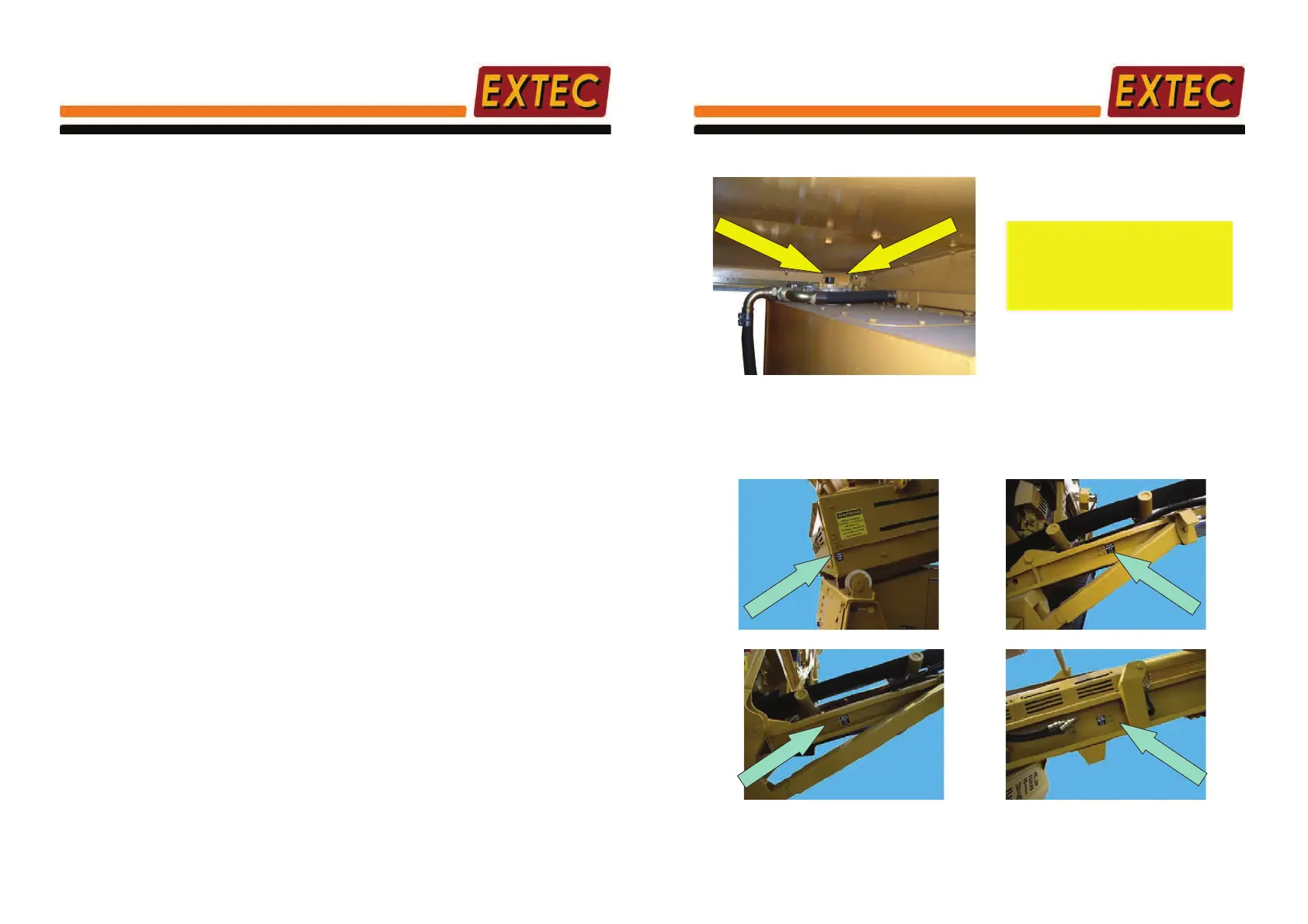

GREASING BEARINGS:

Using suitable equipment, all bearings must be greased every week. See following pictograms

for details of grease points.

WARNING:- NEVER USE GREASE CONTAINING MOLYBDENUM. DOING SO MAY

CAUSE DAMAGE TO MACHINE PARTS AND WILL INVALIDATE ANY WARRANTY.

Feeder bulkhead grease point

Fines Side Conveyor bulkhead grease point

Tail Conveyor bulkhead grease point

Mid-Grade Conveyor bulkhead grease point

G

r

e

a

s

e

P

o

i

n

t

G

r

e

a

s

e

P

o

i

n

t

G

r

e

a

s

e

P

o

i

n

t

G

r

e

as

e

P

o

i

n

t

Section 4 Page6

Loading...

Loading...