E-7

1) Raise screenbox rear

4.7 SCREEN MESH REPLACEMENT

WARNING:- The machine MUST be switched off and ignition key REMOVED before making any

adjustments.

The screen meshes and punched plate can be changed if desired for different sizes of product or

to replace damaged or worn out meshes/punched plate. To fit the screen meshes/punched plate,

proceed in the following manner :-

SCREENBOX BOTTOM DECK MESH ACCESS

To aid in changing the screenbox

mesh & clearing any blockages,

the Screenbox can be raised and

lowered at the front and back

independently of each other.

2)Locate pin to lock teleleg in raised position

3) Raise Screenbox front

4) Locate both screen mesh change

lock-out legs

Mesh

change lock-out

SCREENBOX MESH REMOVAL/FITTING

Using the Ratchet's on either side of screenbox

retract the tension spring bar back to the end of

the sideplate slots. The existing mesh can now

be removed by lifting and unhooking from the

front mesh hook.

Screen mesh tensioning ratchet

BOTTOM DECK MESH REMOVAL

When finished, remember to release both

lock-out legs before lowering screenbox

Screenbox

Up/Down

Mesh Change

Up/Down

L/H Side of Chassis

L/H Side of Chassis

Section 4 Page17

E-7

SCREEN MESH REPLACEMENT

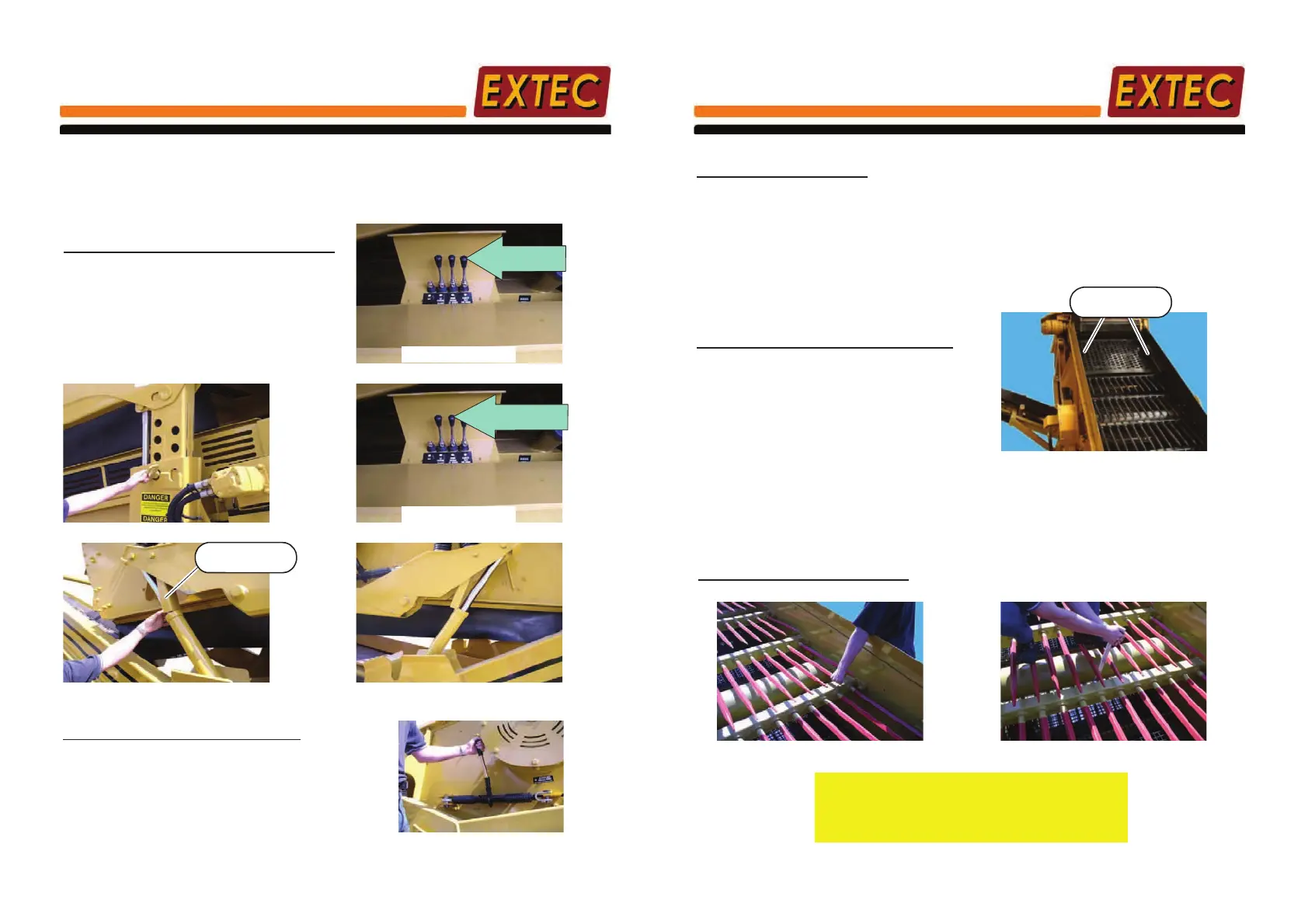

SCREENBOX MESH FITTING

Before changing screen mesh ENSURE the capping rubber is in good condition.

Insert mesh into the box on the bottom deck and anchor one end around the front mesh hook.

Rest the screen mesh on the cross supports and using the Ratchet's either side of the screenbox

extend the tension spring bar along the sideplate slots until the correct tension is achieved.

Restart the machine and run the screenbox motor, if the meshes rattle or make any noise, stop

the machine and apply further tension.

BOTTOM DECK MESH FITTING

TOP DECK PUNCHED PLATE FITTING

Insert punched plate into the box on the top deck and anchor both sides under the clamps. Using

an air gun or other siutable device, tighten the clamps, SIMULTANEOUSLY until the correct

tension is achieved. Restart the machine and run the screenbox motor, if the punched plate

rattles or makes any noise, stop the machine and apply further,

EQUAL

tension to both sides.

Top deck punched plate

SCREENBOX PUNCHED PLATE REMOVAL

Using a suitable device loosen the clamps on

either side of the screen box. When loosened

sufficiently the existing mesh can now be easily

removed.

TOP DECK PUNCHED PLATE REMOVAL

Punched plate

clamp

TOP DECK TINE CHECK/REMOVAL

Check Tine by shaking it as shown

If Tine is loose, tighten the nut on the

back of the crossmember as shown

Alternitavely, if Tine is damaged or bent, loosen

the nut on the back of the crossmember and

remove the faulty Tine. Insert a new Tine and

re-tighten the nut.

Section 4 Page18

Loading...

Loading...