E-7

SCREENBOX MAINTENANCE

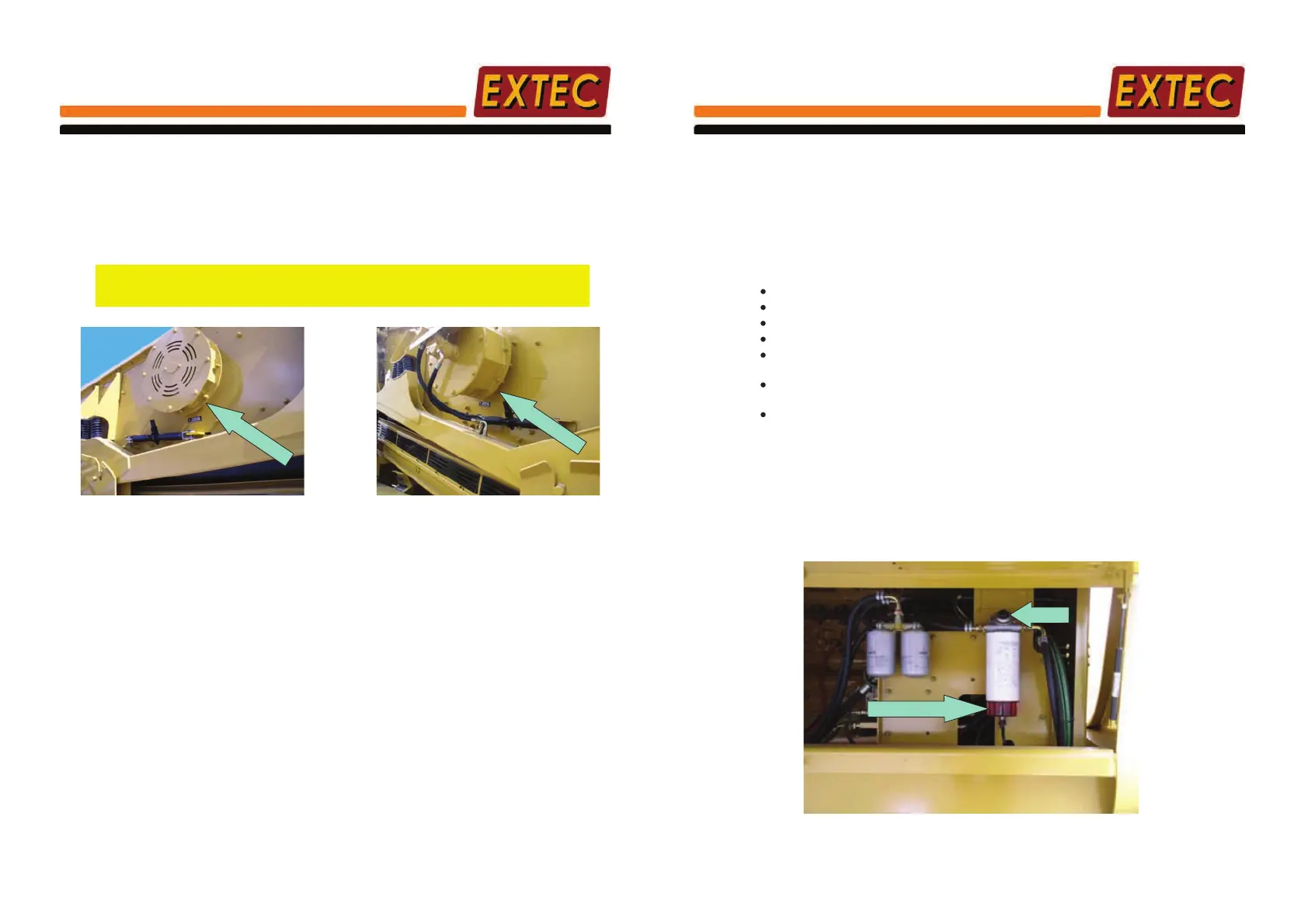

Screenbox non-drive side grease point

Screenbox drive side grease point

G

r

e

a

s

e

P

o

i

n

t

G

r

e

a

s

e P

o

i

n

t

After running the Screenbox for the first 50 hours, the Screenbox must be cleaned free of material

and ALL bolts must be checked for tightness.

GREASING BEARINGS:

Using suitable equipment, Screenbox bearings must be regreased every 50 hours with 20 grams of

LGHQ3 grease used per bearing

WARNING!!

-

NEVER

USE GREASE CONTAINING MOLYBENUM. DOING SO MAY

CAUSE DAMAGE TO MACHINE PARTS AND

WILL

INVALIDATE ANY WARRANTY.

Section 4 Page9

E-7

4.4 MACHINE MAINTENANCE - EVERY 250 Hrs

Every 250 hours , the following maintenance must be carried out to ensure the best performance and least

possible breakdowns from your machine:-

1. Follow maintenance instructions laid out in engine manufacturers handbook..

2. Change the hydraulic water trap - REGARDLESS of condition of service indicator.

3. Change the hydraulic tank air breather - REGARDLESS of condition of service indicator.

4. Flush hydraulic system and change the hydraulic filters - REGARDLESS of condition of service

indicator.

To flush hydraulic system, proceed as follows:-

Ensure all material has passed through the screenbox and off the conveyor belts.

Stop machine and replace hydraulic filters with 3 micron flushing filters.

Fit new 10 micron water trap.

Check condition of hydraulic tank air breather, if the service indicator is red,

change it otherwise just clean all dust from the base of the filter.

Run all systems for 4 hours with engine speed set to low revs (DO NOT FEED

MATERIAL INTO MACHINE DURING THIS OPERATION).

Stop machine and replace flushing filters with new 25 micron hydraulic filters.

5. Check for leaks on hydraulic pipes.

6. Inspect condition of conveyor belts and tracking.

7. Inspect condition of all drums and rollers.

8. Inspect all bearings.

9. Check drive belts for wear, swelling, softening & tension - Replace if necessary. (Note:-Tension

should remain constant during the belts working life and should not be Re-Tensioned).

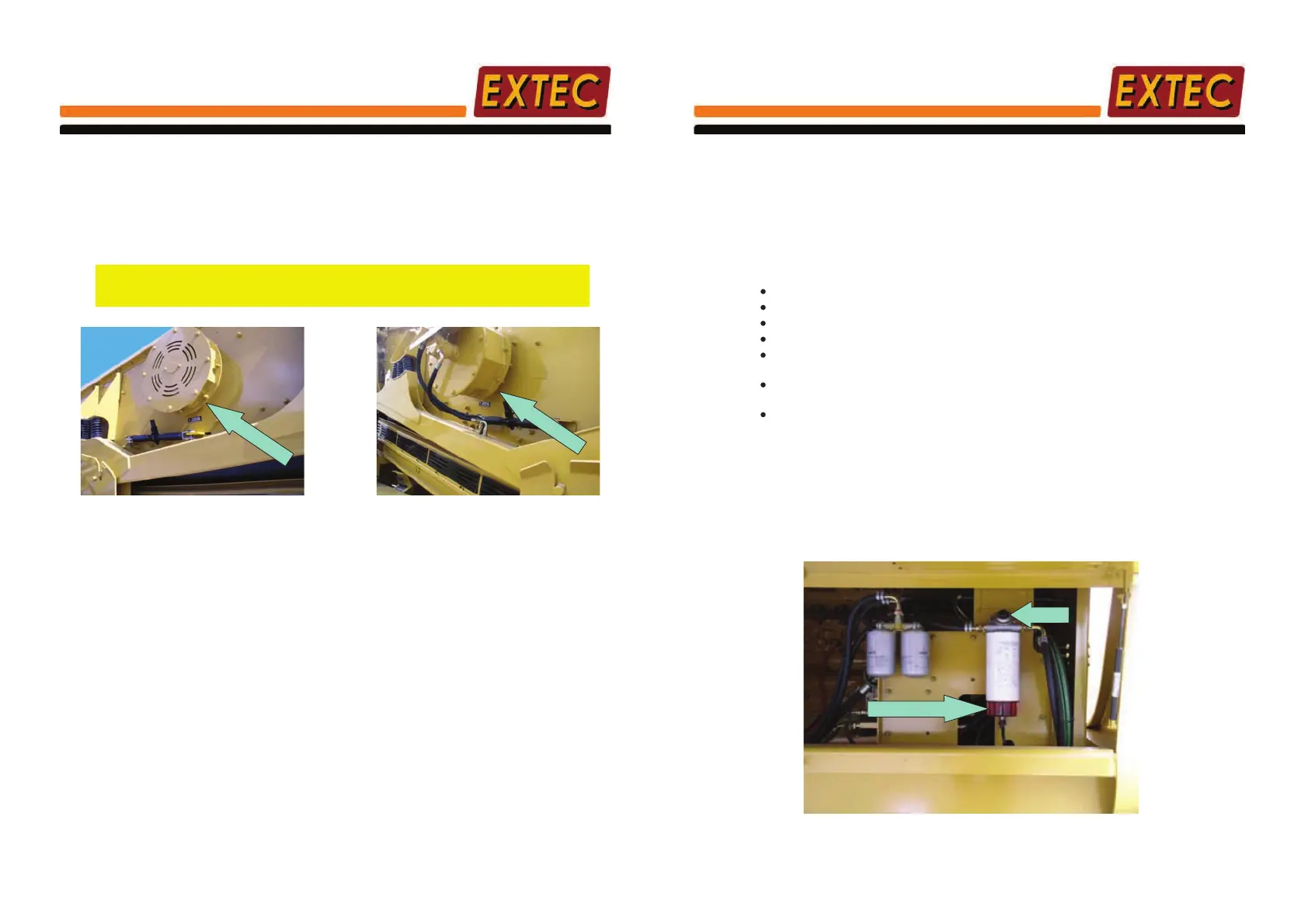

10.Clean out sediment bowl on fuel pre-filter. Folow procedure printed on the side of the filter.

(Note:- When sediment bowl is cleaned out, the fuel system will have to be re-primed).

Fuel filters at rear of machine

SEDIMENT BOWL

PRIMER

Section 4 Page10

Loading...

Loading...