E-7

4.5 MACHINE MAINTENANCE - EVERY 1000 Hrs

Every 1000 hours, the following maintenance must be carried out:-

1. Carry out 250 hr maintenance schedule.

2. Change oil in Feeder Gearbox (see manufactueres handbook).

3. Change diesel filters.

4. Change oil in tracks.

5. Check Track tension. (only tension if necessary).

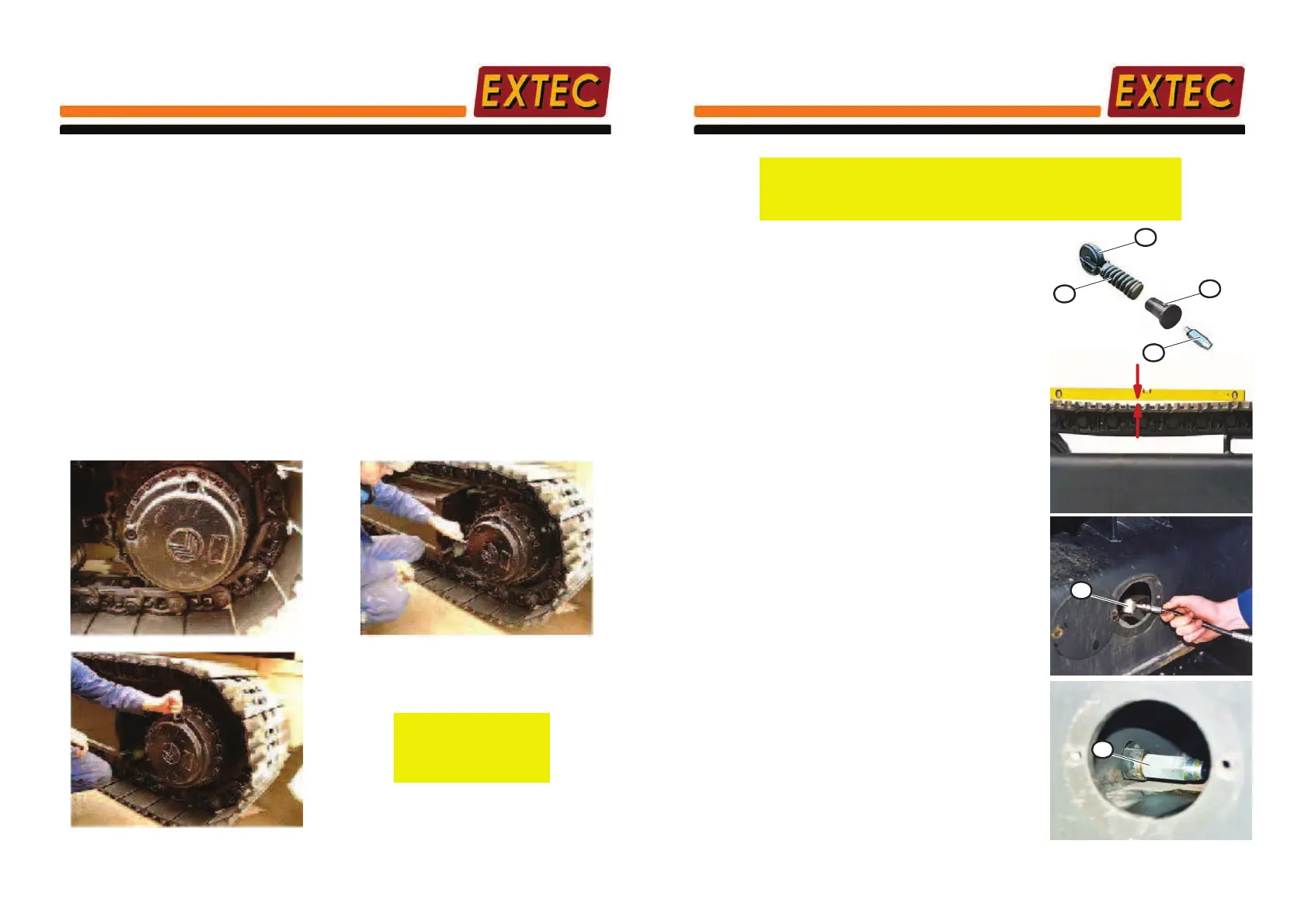

To drain oil from the track gearbox, drive the machine until either one of the drain plugs is at

the bottom of the gearbox. Remove drain plug and oil will drain out. Use a suitable container to

collect waste oil.

Disposing of waste oil must be done in a manner that complies with current environmental

legislation.

To refill track gearbox with oil, drive machine until either one of the drain plugs is at the top

(See Photo). NOTE: - this will only be 1/4 turn of the track gearbox, DO NOT drive machine

any further until oil has been replaced in tracks. Remove both drain plugs as shown in the

photographs below. Fill oil into the top drain plug until it starts to come out of the other drain

plug. Replace both plugs BEFORE driving machine. Each track gearbox will have to be

maintained separately.

Track Gearbox in correct position to refill oil.

Remove level plug

Remove filler plug

When changing

oil in tracks, Use

EP90 Gear Oil.

Section 4 Page11

E-7

MACHINE MAINTENANCE - TRACK ADJUSTMENT

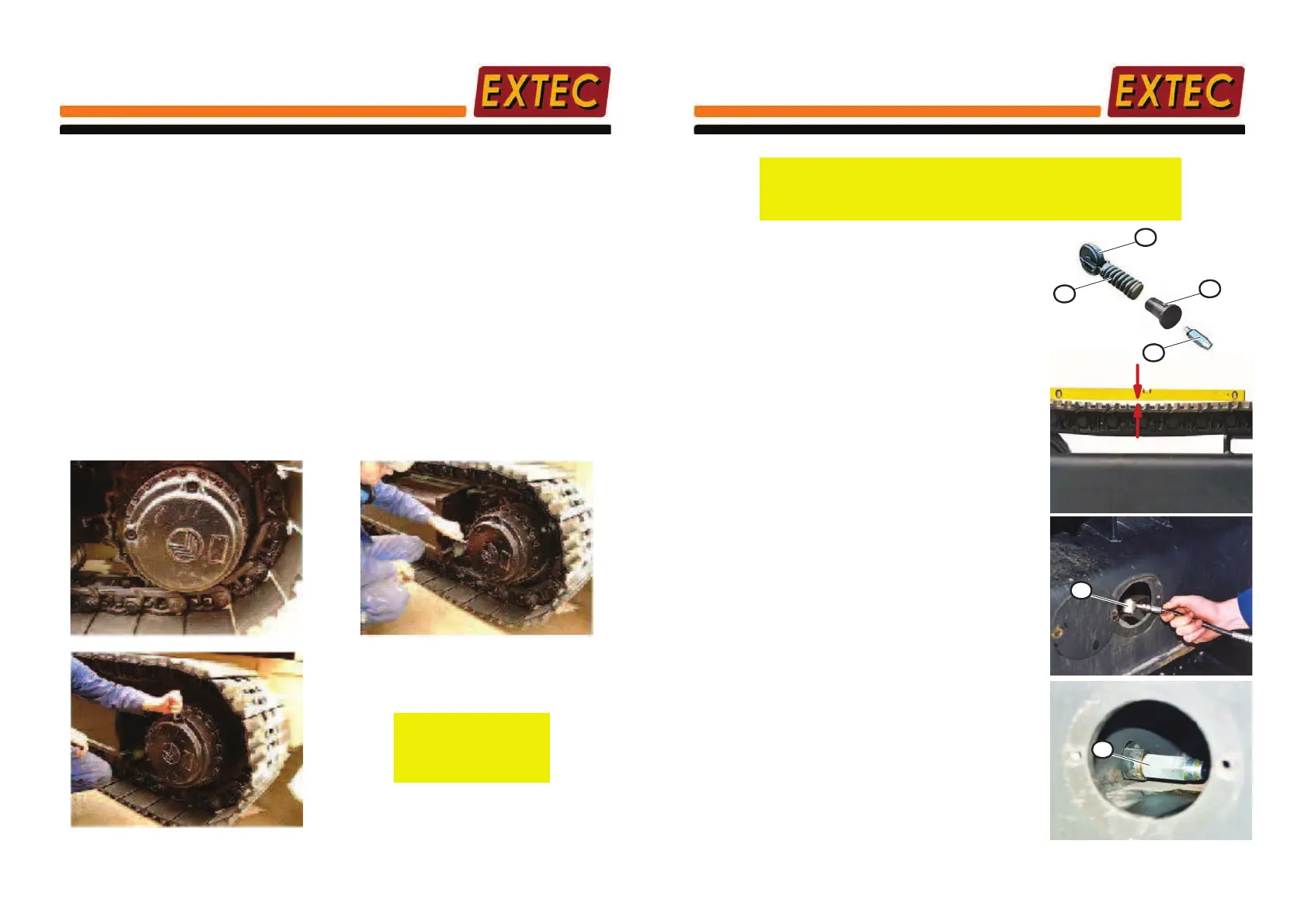

TRACK ADJUSTMENT.

After maintenance or over time the Track will become slack and will

have to be adjusted. The adjustment of the tracks operates through

a Tensioning Cylinder, (C). When the Cylinder is filled with grease it

extends and pushes the Spring Tension unit, (B), and the Idler, (A),

forward. The grease is filled through the Track Adjuster Grease

Valve, (D).

TRACK ADJUSTMENT SETTINGS.

In order to establish if the track requires tensioning, move the Host

machine a few metres forwards and backwards on level ground.

This allows the tracks to adopt their natural degree of tension.

Note: Do not slew the machine.

Using a straight edge and a measuring tape, measure the droop of

the Track Group as shown at (E). For this particular Track Set, the

droop should not exceed 30mm.

Note: It is also important that the Track is not tensioned too tightly as

this places excessive loads on the Gearbox and Idler bearings. It will

also lead to accelerated wear and premature failures.

INCREASING THE TRACK TENSION.

To increase the tension of the Track:

(i) Remove the inspection cover on the side of the Track

Frame, as shown at (F).

(ii) Ensure that the Track Adjuster Valve, (H), is tight.

(iii) Attach the special grease gun connector, (G), to a grease

gun and fit it onto the Track Adjuster Valve, (H).

(iv) Pump grease into the valve until the droop of the Track is

correct.

(v) Move the Host machine backwards and forwards a few times

more and then re-check the droop. Add more grease if

required.

(vi) Check for any escaping grease around the Tensioning unit

and finally close the inspection cover when finished.

Important: Ensure that the correct grease is used.

RELEASING THE TRACK TENSION.

To the release the tension on the Tracks:

(i) Remove the inspection cover on the side of the Track Frame

as shown at (F).

(ii) Loosen the Track adjuster valve, (H), by turning it one half

turn anticlockwise.

(iii) Grease should now escape slowly from the Track

Tensioning Cylinder and the Track should slacken.

(iv) If the Track fails to loosen, apply a little pressure to the Idler

end of the Track to push the Idler group in.

(v) Replace the inspection cover when completed.

WARNING !

Grease under pressure can cause serious injury. Never unscrew a Track

Adjuster Valve by more than a 1/2 turn, when the Track is under tension.

A

B

C

D

30mm

(E)

(F)

G

H

Section 4 Page12

Loading...

Loading...