Operation - RT10

28

PTO Driveline Length Check

Due to variations in distances between tractor PTO

shafts and implement input shafts, drivelines may

need to be shortened or a longer shaft may be

required.

When fitting the implement to the tractor, the

PTO driveline, with telescoping sections, must

be inspected. When the sections are at the most

compressed operating position, the sections must

not “bottom out”.

At its shortest length, there must be at least 2 in.

(50.8 mm) of clearance between each section end

and opposite section end at the most compressed

operating position.

When the sections are at the most extended

position, there must be sufficient engagement

between the sections.

At its farthest operating extension, a minimum

section engagement of 33% of shaft length must

be maintained.

PTO Driveline Bottoming Out Check

Stop the engine and leave the operator’s position

(see “Leaving The Operator’s Position” on page

24).

Make sure the PTO driveline and all rotating

components have come to a complete stop before

leaving the operator’s position (if applicable).

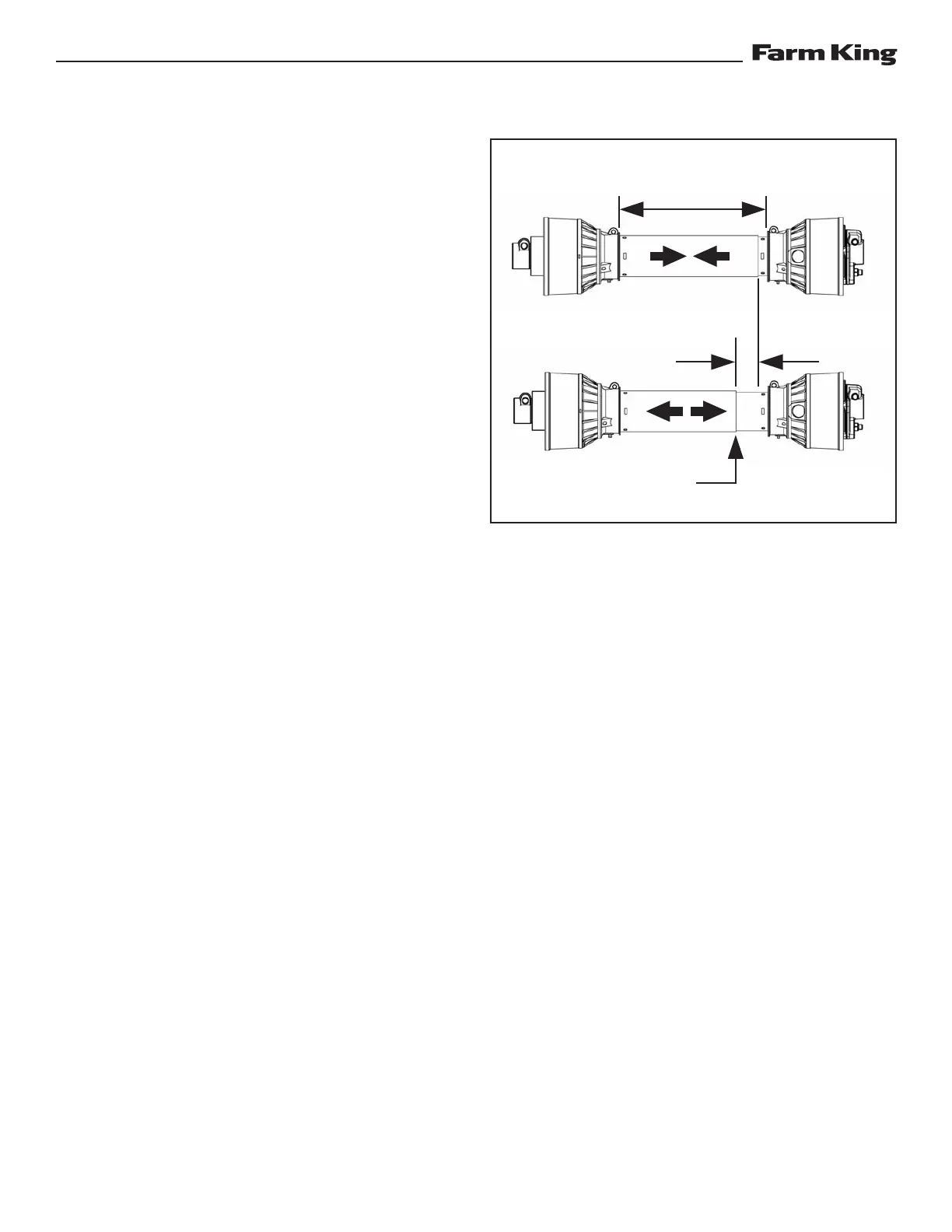

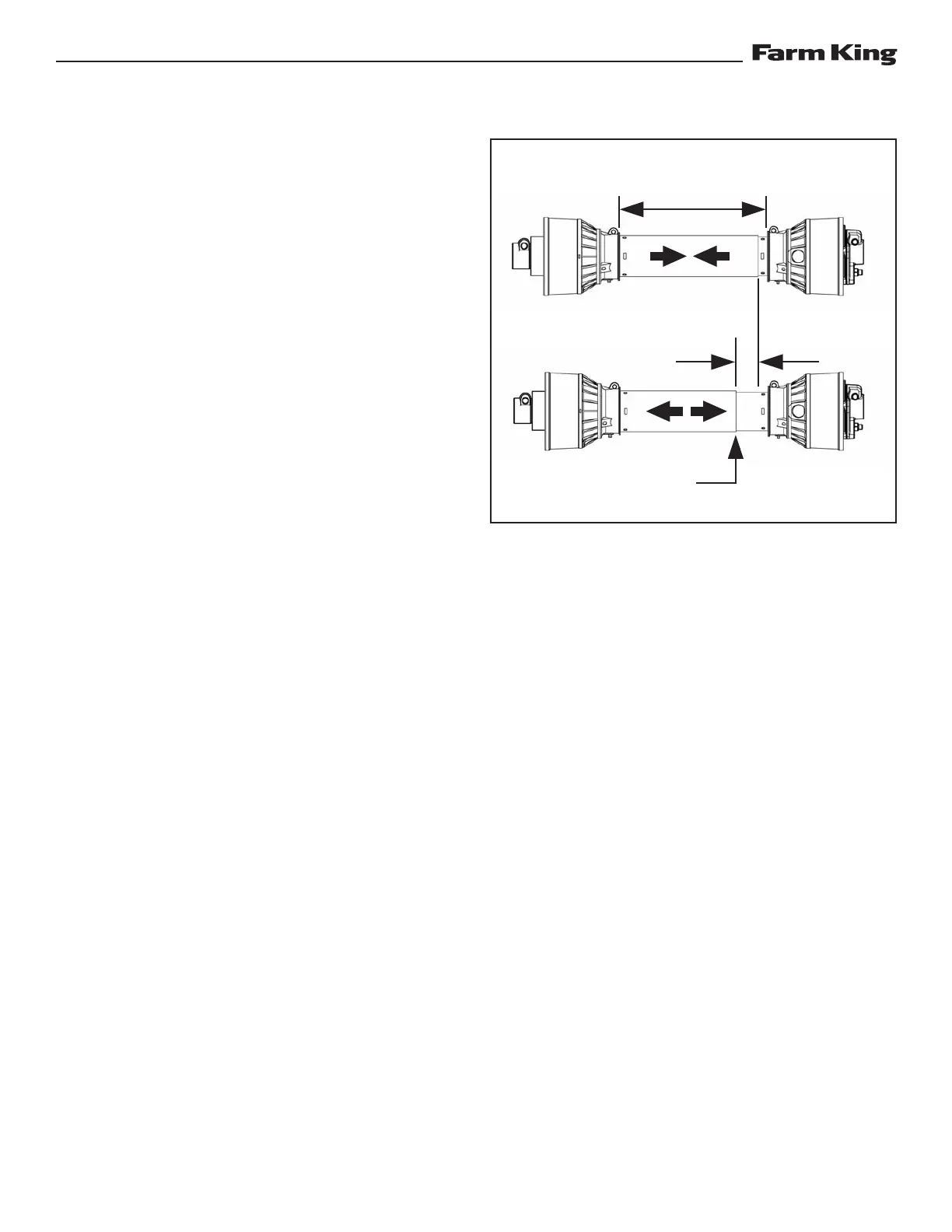

Figure 21

1. Disconnect the PTO driveline from the tractor

and slide the PTO driveline together until fully

retracted (compressed).

2. Measure the retracted (compressed) length of

PTO driveline [Figure 21].

3. Extend the PTO driveline 2 in. (50.8 mm) from

the retracted length and place a mark on the

inner guard at the end of the outer guard

[Figure 21].

4. Reattach the PTO driveline to the tractor PTO

shaft.

5. Enter the operator’s position. Start the engine.

6. With the rear PTO DISENGAGED, raise and

lower the implement and watch the PTO

driveline extend and retract.

7. If the outer PTO driveline guard slides in

(retracts) over the mark at any point of travel,

the PTO driveline needs to be shortened.

MARK INNER

GUARD HERE

RETRACTED

(COMPRESSED LENGTH)

2” (50.8 mm)

Loading...

Loading...