Maintenance - RT10

41

Lubrication

Recommendations

Always use a good quality multi-purpose / lithium

base grease when lubricating the equipment.

IMPORTANT

Do not over-grease bearings. Greasing too

often can damage seals and lead to premature

bearing failure.

• Always use a hand-held grease gun.

• Clean fitting before greasing, to avoid injecting

dirt and grit.

• Replace and repair broken fittings immediately.

• If fittings will not take grease, remove and clean

thoroughly. Replace fitting if necessary.

WARNING

AVOID INJURY OR DEATH

Stop engine, set brake, remove ignition key,

and wait for all moving parts to stop before

servicing, adjusting, repairing, or unplugging.

Support the equipment with blocks or safety

stands before working beneath it.

Follow good shop practices:

• Keep service area clean and dry

• Be sure electrical outlets and tools are

properly grounded

• Use adequate light for the job.

Use only tools, jacks, and hoists of sufficient

capacity for the job. Replace and secure all

shields removed during servicing before

operating.

Use heavy leather gloves to handle sharp

objects.

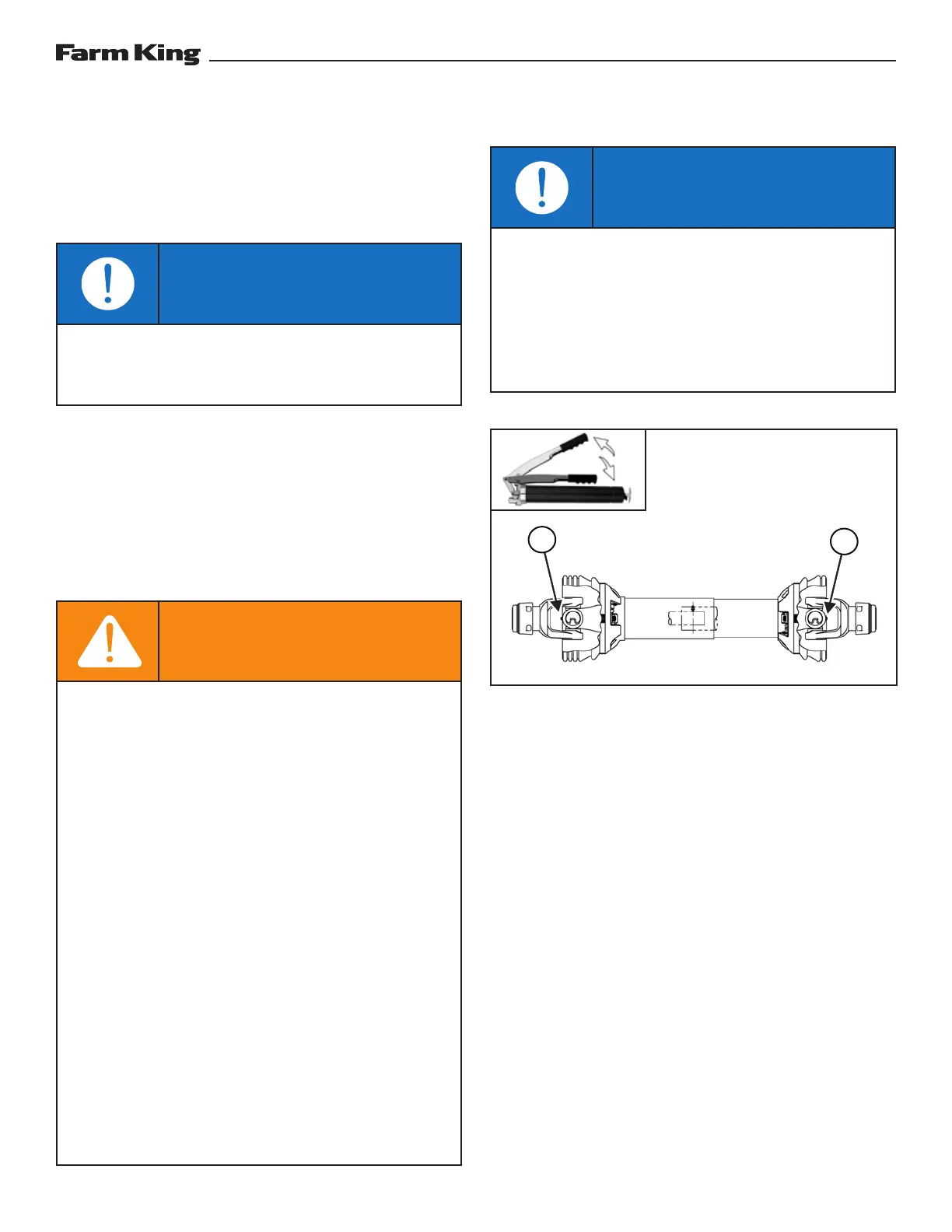

PTO Driveline Grease Locations

IMPORTANT

Fluid such as engine oil, hydraulic fluid,

coolants, grease, etc. must be disposed of

in an environmentally safe manner. Some

regulations require that certain spills and leaks

on the ground must be cleaned in a specific

manner. See local, state and federal regulations

for the correct disposal.

Figure 35

Apply two to three pumps of grease to the cross

and bearings (Item 1) on the PTO driveline [Figure

35].

Grease every 8 hours.

NOTE: Images may not show your exact PTO

driveline but the procedure is correct.

2-3

1

1

Loading...

Loading...