64

MAINTENANCE

Pulleys

Avoid the conditions listed below, which could cause early wear of the pulleys (fixed or expanding).

• lack of alignment, lack of parallelism, breakage, high wear and lack of eccentricity

• dust, grease, dirt and also a high level of humidity which would cause the formation of condensate. These substances

depositing between the surfaces of the belt and those of the pulley can cause the system to work in anomalous conditions.

Before adjusting the pulley, measure the actual work rolling pitch diameter and determine the required diameter, then remove

the belt. For single-groove pulleys, loosen the locking screw of the movable disk and turn it on the threaded hub, checking the

obtaining of the required rolling pitch diameter with the belt. Lightly oil the thread in case of sliding difficulty. Tighten the screws

evenly, checking the alignment of the transmission, refit the belt and correctly tighten it. For pulleys with two grooves, proceed

in the same way, carefully checking (measuring the opening with a gauge and measuring the work diameter of the belt) that the

grooves are equally adjusted.

Periodically check groove wear. The working life of the pulleys mainly depends on correct performance of the belt tensioning and

transmission alignment operations. After a certain period of operation the wear will in any case alter the geometric characteristics

of the grooves (generally more pronounced in pulleys of smaller diameter) along with reduced life of the belts. In this case it is

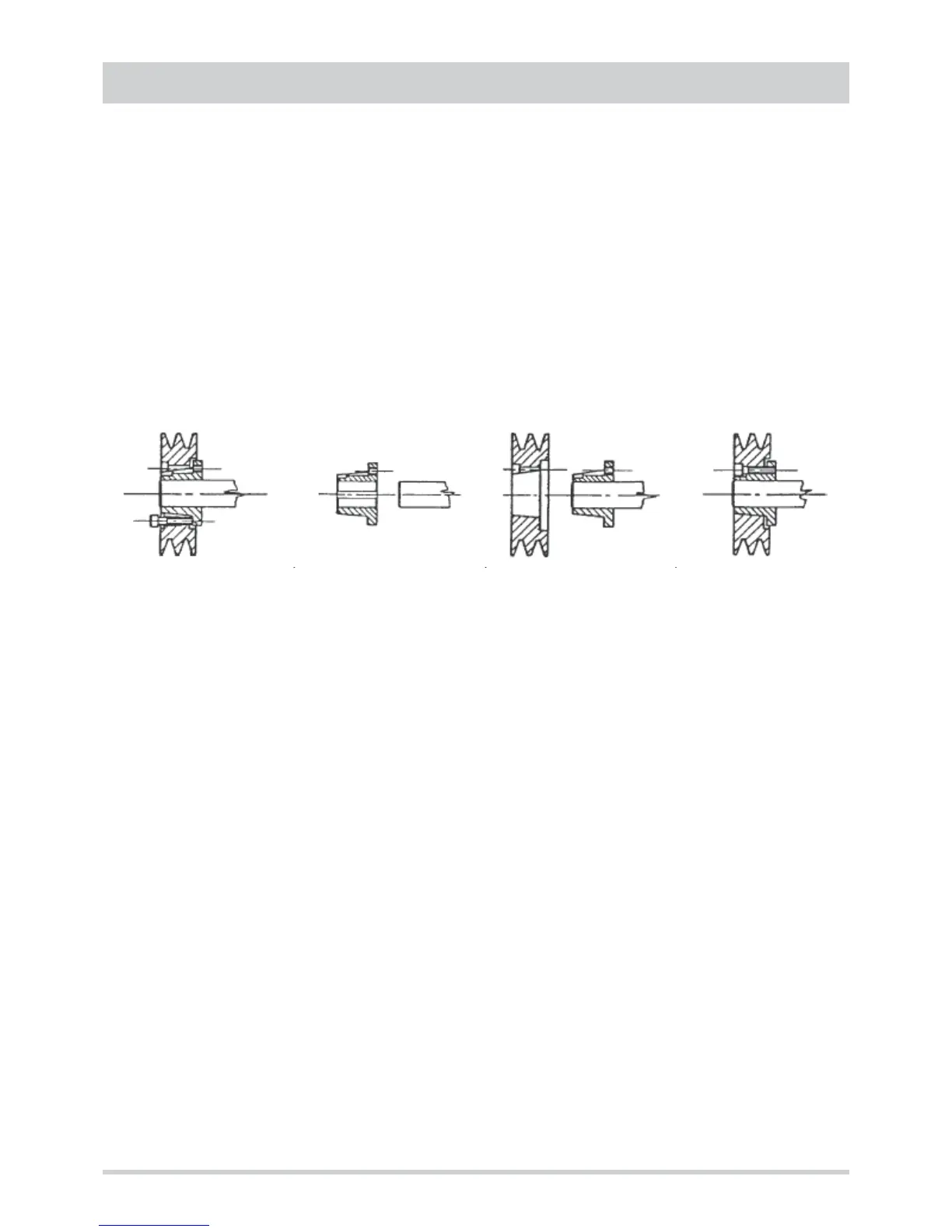

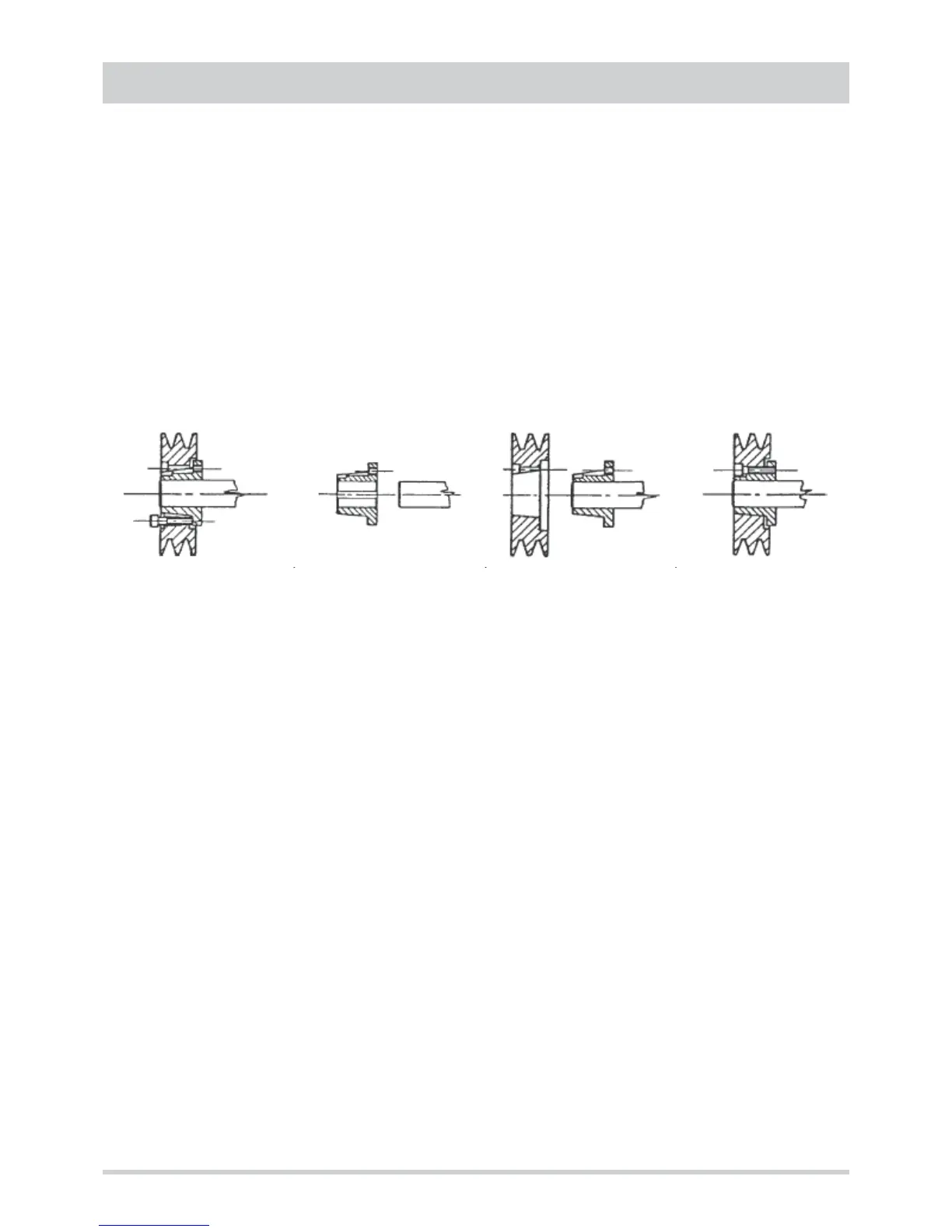

necessary to replace the most altered pulley or the entire transmission. For pulleys with taper-lock bushing, replacement is carried

out as indicated in the following figure.

The shaft and taper fit must be cleaned but not greased. Oil the screws and tighten them evenly and alternately. To remove the

pulleys without bushing, it is necessary to remove the fixing, consisting of :

• Grub screw on threaded hole in the hub, for the pulleys installed on fans.

• Screw and washer or cap, on threaded hole in the shaft, for the pulleys installed on motors.

Carefully clean the shaft before fitting the new pulley.

If the new pulleys are not supplied by us, make sure they are statically and dynamically balanced.

Electric motor

Regular cleaning of the electric motor ensures a longer life, since it increases the ability of the housing to dissipate the heat gene-

rated. The cooling air slots must always be kept free.

Inspection and maintenance intervals depend on operating and environmental conditions.

Bearings in good condition indicate low friction values and thus electrical absorption kept within the necessary minimum values,

to the advantage of motor life. The basic theoretical fatigue life L10h (in conformity with standard ISO 281/1 for bearings without

additional axial radial loads) is over 50,000 hours. Those supplied are prelubricated double-shielded type.

A periodical check for any noise or possible whirring can reduce the need for maintenance operations. When ordering replacement

parts, specify the code and type of motor indicated on the plate. The standardised components are available at all specialised

dealers.

Internal and return air fan

Regular general fan cleaning will ensure an optimum passage of air and therefore high efficiency. Bearings in good condition

indicate low friction values, thus contributing to limiting electrical absorption, to the advantage of the electric motor, while also

reducing the possibility of excessive wear of the drive belt.

The bearings of all the fans are chosen according to type and size to guarantee a life L10h = 40,000 hours of work with reference

to standard ISO 281/1. This value was calculated in the most unfavourable load conditions for the bearing, i.e. considering the

max. permissible radial load. In the operating conditions in which the fans are generally used, the average life is much longer.

Seasonally, before starting the unit, check the fixing of the fans to the unit's structure.

Also make sure the fan wheel is perfectly straight and that it has not undergone dangerous unbalancing causing anomalous vi-

brations and noise.

Loading...

Loading...