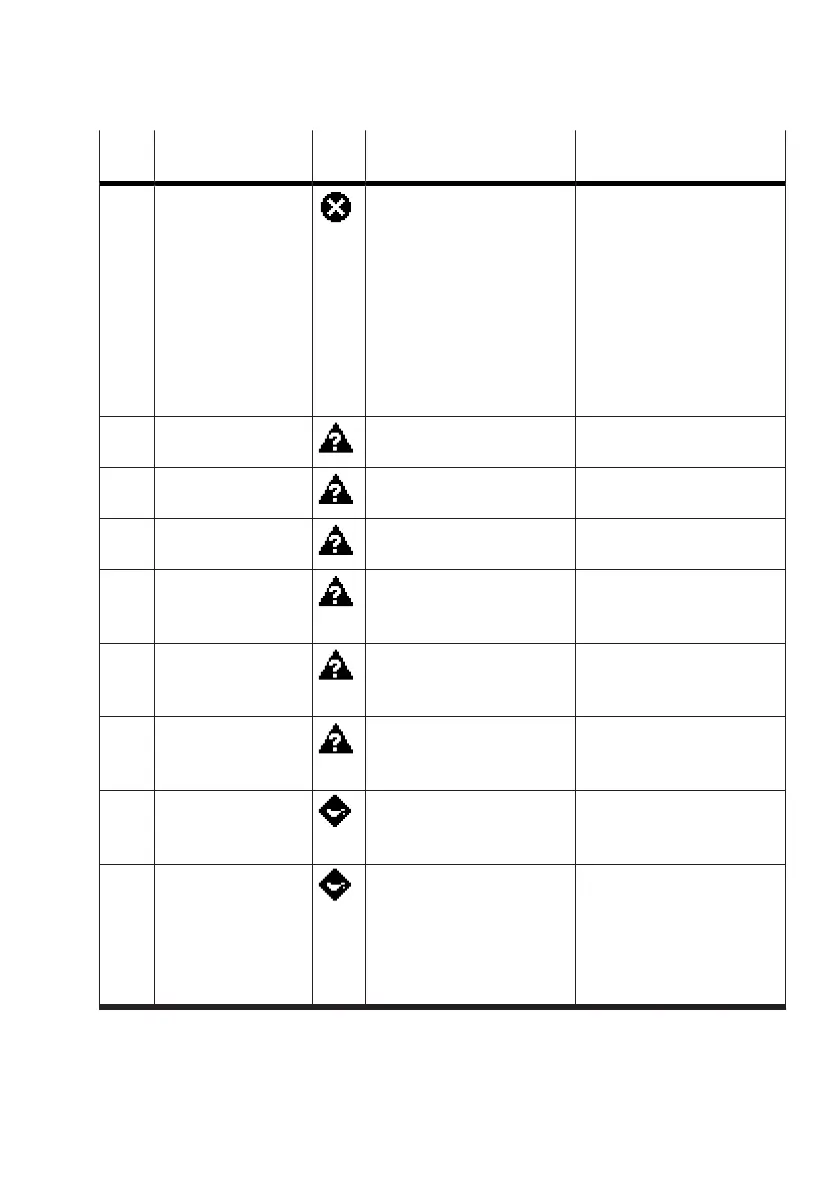

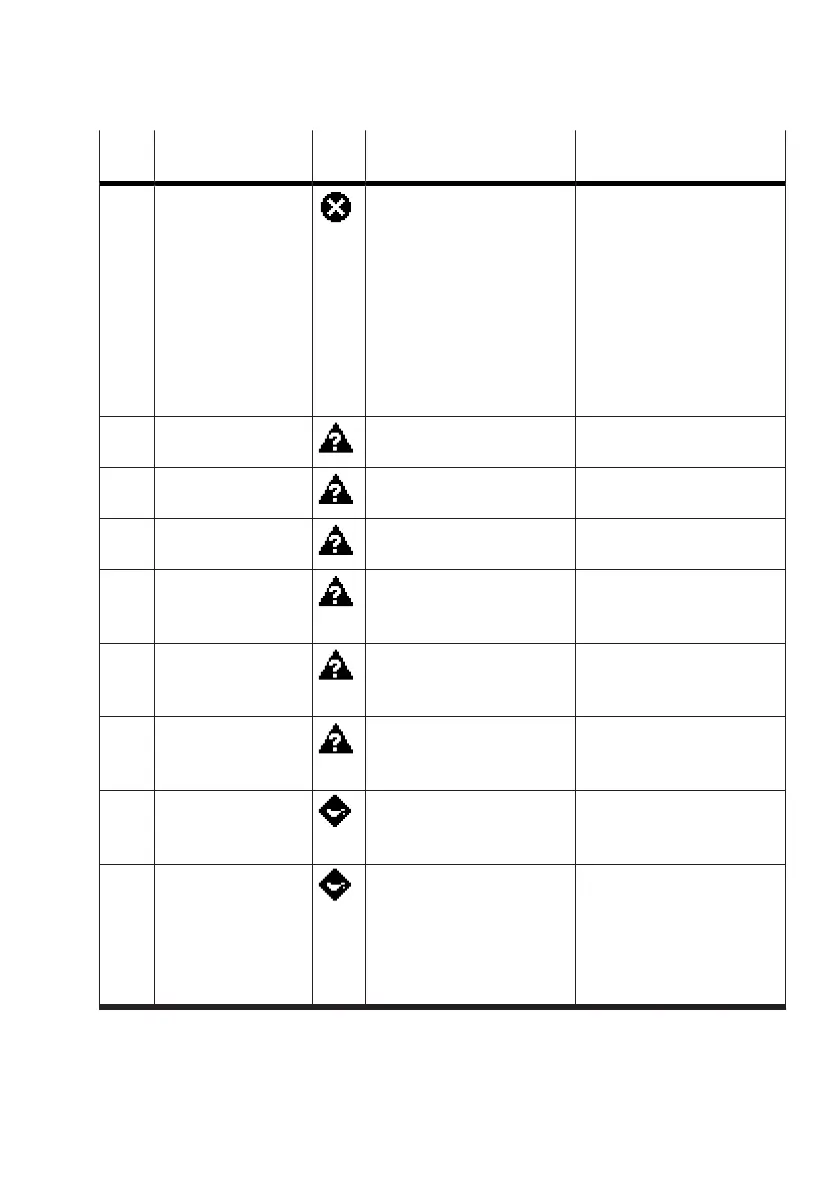

ID Message NAM

UR

1)

Possible cause Notes/remedies

416 Initialization failed:

Timeout control

parameter

–

Increased friction with

drive or process valve

–

Fluctuations in supply

pressure

–

External potentiometer

outside specification

–

Operation of drive and/or

process valve out of speci-

fication

–

Repeat initialisation.

If the initialisation

repeatedly fails, con-

tact Festo Support

è

www.festo.com/sp.

–

Service drive or process

valve.

– Check supply pressure.

–

Check specification of the

external potentiometer.

790 Setpoint signal below

valid range

–

Setpoint signal below

3.8 mA

–

Check analogue input

signal.

791 Setpoint signal above

valid range

–

Setpoint signal above

20.5 mA

–

Check analogue input

signal.

798 Supply pressure too

high

–

Supply pressure above

8 bar

–

Check supply pressure.

799 Supply pressure too

low

–

Supply pressure below

1.4 bar

–

Clogged filter

–

Check supply pressure.

–

Check filter.

828 Temperature in

device too high

–

Temperature above 80 °C

–

Media influences or envi-

ronmental influences

–

Check operating condi-

tions.

829 Temperature in

device too low

–

Temperature below -40 °C

–

Media influences or envi-

ronmental influences

–

Check operating condi-

tions.

918 Above defined supply

pressure limit

2)

–

Set threshold value

exceeded

–

Check supply pressure.

–

Adjust threshold value if

necessary.

919 Below defined supply

pressure limit

2)

–

Set threshold value under-

shot

–

Clogged filter

–

Too many consumers on

the compressed air line

–

Check supply pressure.

–

Adjust threshold value if

necessary.

–

Check filter.

–

If necessary, install buffer

volume.

Loading...

Loading...