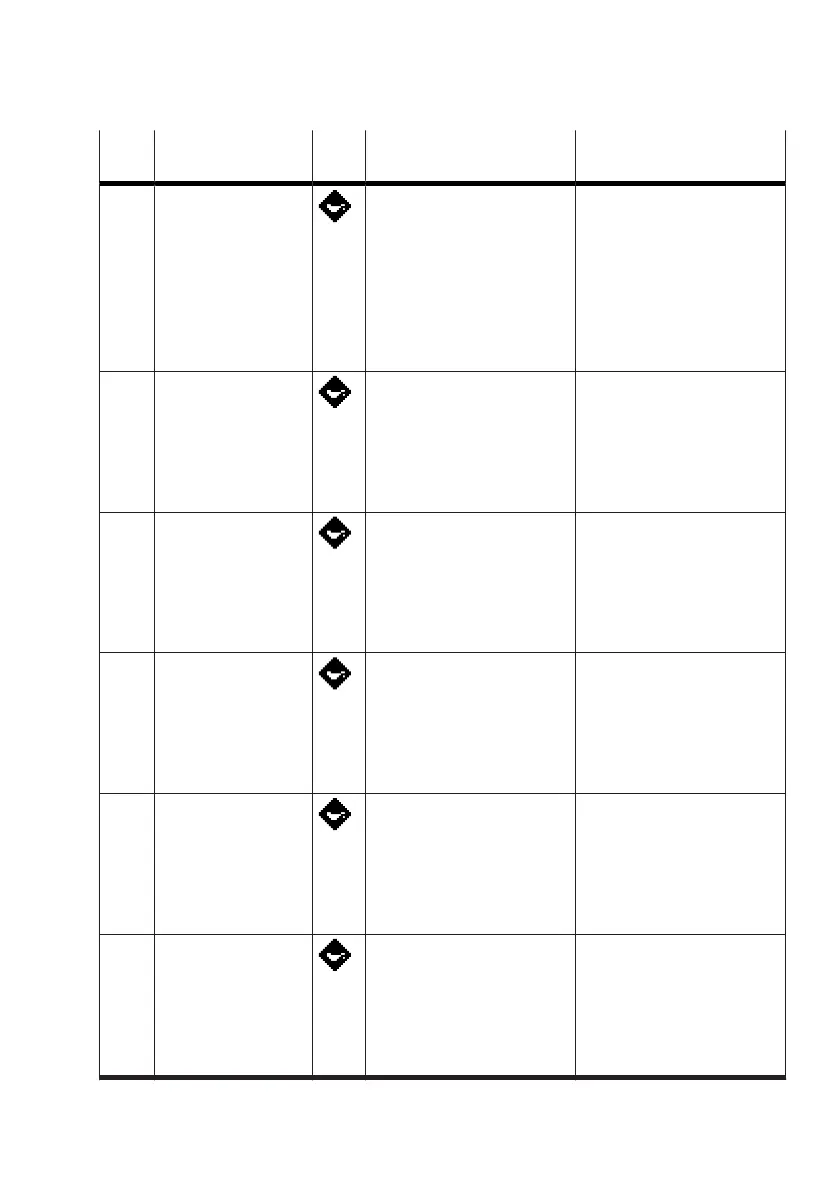

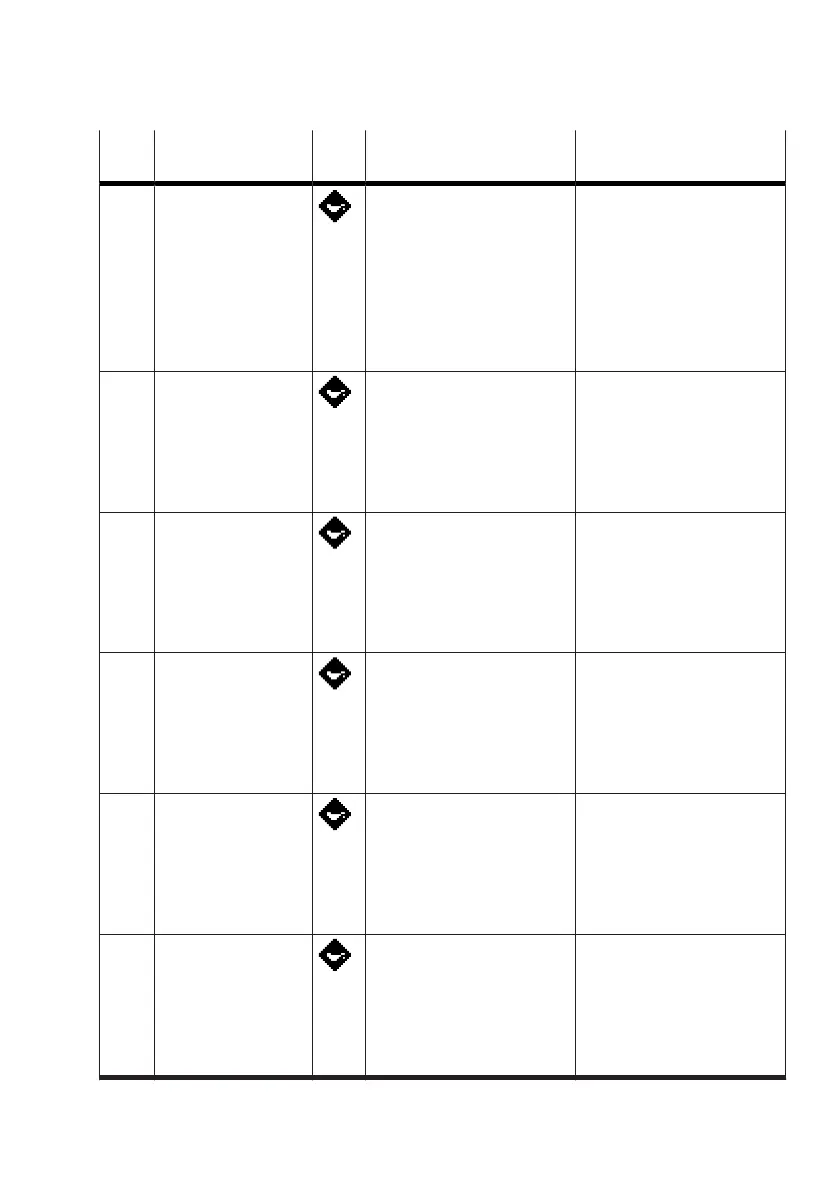

ID Message NAM

UR

1)

Possible cause Notes/remedies

1086 PST stopped: Too

long duration com-

pared to absolute

upper limit

2)

–

Increased friction with

drive or process valve

–

Set threshold value

exceeded

–

Low supply pressure

–

Increased resistance in the

compressed air lines

– Wear of the positioner

–

Service the drive or

process valve and replace

if necessary.

–

Check supply pressure.

–

Check compressed air

lines.

–

Replace positioner.

1087 PST stopped: Out of

valid position range

when back at starting

position x1

2)

–

Positional drift due to

compressed air leakage

–

Movement caused by

external forces

–

Increased noise of the

position sensor

–

Check for compressed air

leakage.

–

Check for external forces.

–

If necessary, adjust values

of the tolerance target

position (Tol_target).

1088 PST stopped: Out

of valid position

range during move-

ment from x1 to x2

2)

–

Positional drift due to

compressed air leakage

–

Movement caused by

external forces

–

Increased noise of the

position sensor

–

Check for compressed air

leakage.

–

Check for external forces.

–

If necessary, adjust values

of the tolerance target

position (Tol_target).

1089 PST stopped: Out of

valid position range

at position x2

2)

–

Positional drift due to

compressed air leakage

–

Movement caused by

external forces

–

Increased noise of the

position sensor

–

Check for compressed air

leakage.

–

Check for external forces.

–

If necessary, adjust values

of the tolerance target

position (Tol_target).

1090 PST stopped: Out

of valid position

range during move-

ment from x2 to x1

2)

–

Positional drift due to

compressed air leakage

–

Movement caused by

external forces

–

Increased noise of the

position sensor

–

Check for compressed air

leakage.

–

Check for external forces.

–

If necessary, adjust values

of the tolerance target

position (Tol_target).

1091 PST stopped: Out of

valid position range

when back at starting

position x1

2)

–

Positional drift due to

compressed air leakage

–

Movement caused by

external forces

–

Increased noise of the

position sensor

–

Check for compressed air

leakage.

–

Check for external forces.

–

If necessary, adjust values

of the tolerance target

position (Tol_target).

Loading...

Loading...