Commissioning

10 © Festo Didactic GmbH & Co. • MPS

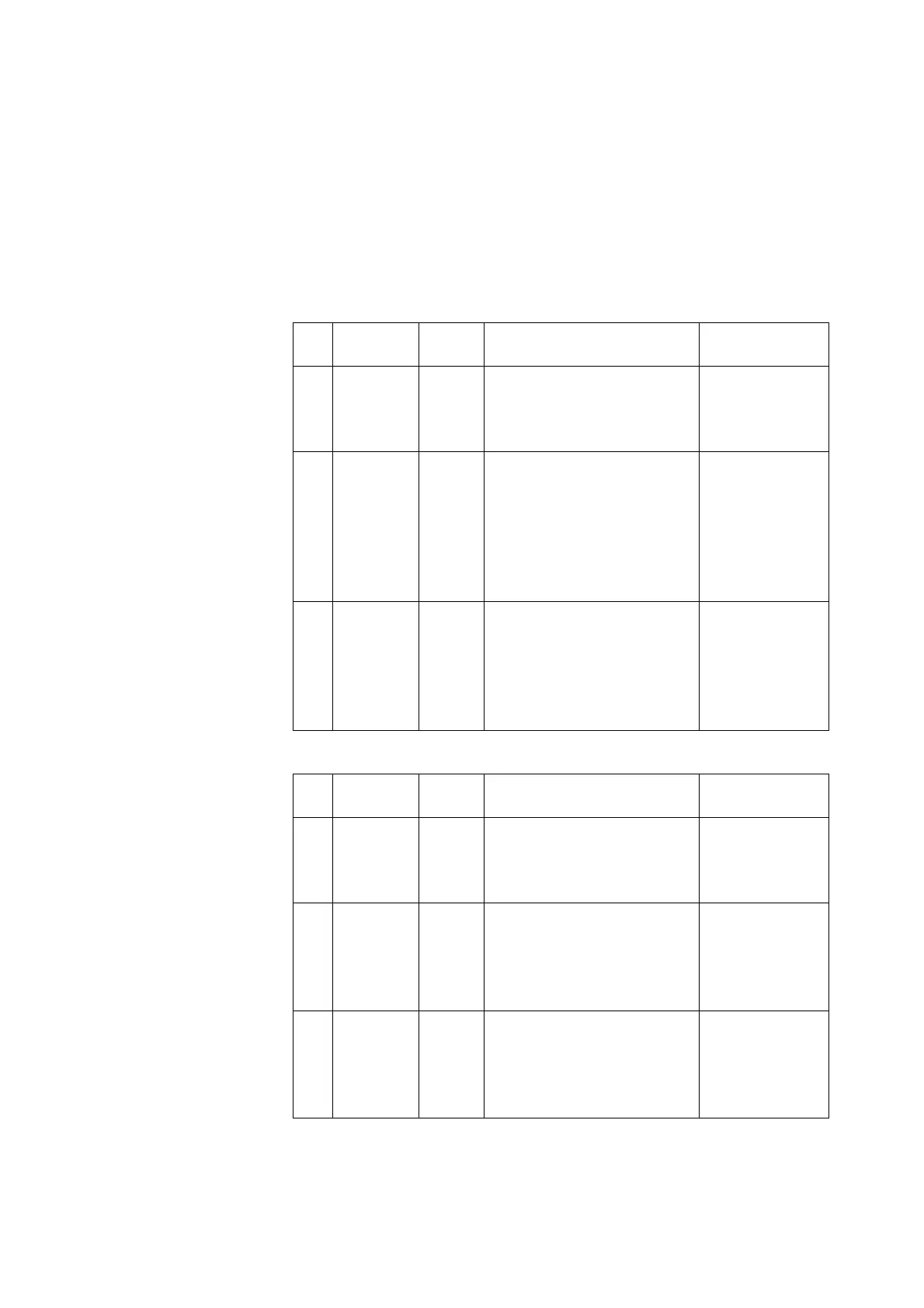

Execution/Documentation

Please complete the list regarding the elements shown and numbered in the

pictures above.

No. Name Ident. Description Page #

Ex.1 Start-button S1 Push button with light on the Control

Panel, normally open contact,

connected to a PLC-input

no data sheet

Panel: inputs

Ex.2 Proximity

switch,

inductive

2B2 Inductive switch, normally open

contact, activated by a magnet ring in

the piston rod of the flat cylinder with

non-rotating piston rod, send the

information “piston rod of the cylinder

is in up position” to the PLC-input

SME-8-S-LED-24

Station: inputs

Station: pneumatic

PLC-board: inputs

Ex.3 Pneumatic

gripper

3A1 Double acting parallel gripper,

actuated by 2 parallel acting cylinders

inside, with magent ring for end-

position detection, gripper power 27 N

open and close

HGP-10-A

Station: outputs

Station: pneumatic

PLC-board: outputs

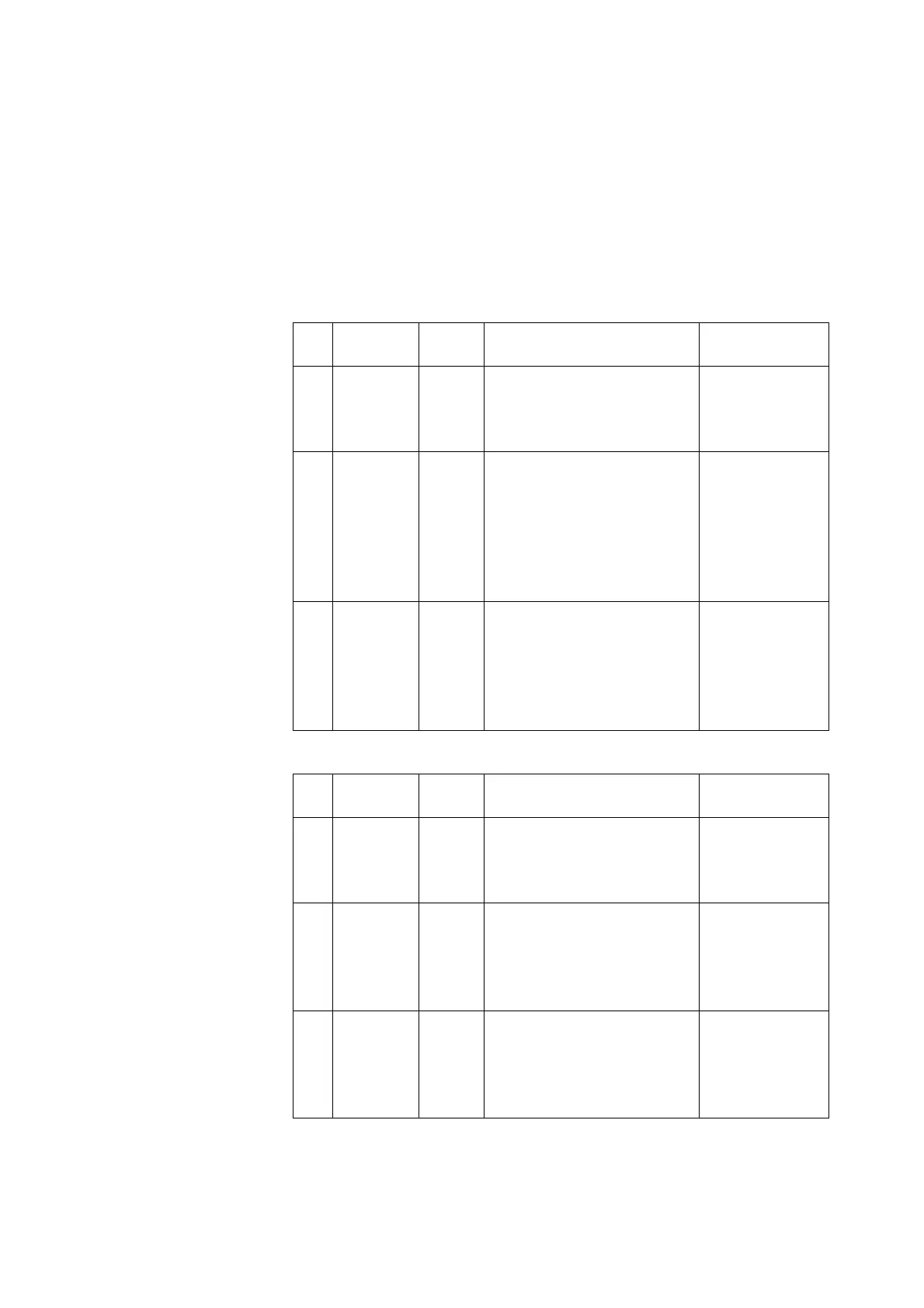

No. Name Ident. Description Page #

1 Retro

reflective

sensor

3B1 Retro reflective optical sensor, send out

an infra-red signal and measure the

reflection of the light.

SOEG-L-Q30-PA-S-2L

Station: inputs

PLC-board: inputs

2 Pneumatic flat

cylinder non-

rotating

2A1 Flat cylinder with non-rotating piston

rod, double acting, non-rotating by the

form of the piston rod, with magnet ring

for end-position detection

DGO-12-225-P-A

Station: outputs

Station: pneumatic

PLC-board: outputs

3 Light barrier

sender

IP_N_FO Infrared sender to the previous station,

maximum range 6000 mm

SOEG-S-Q30-S-L

Station: inputs

PLC-board: inputs

Loading...

Loading...