Commissioning

© Festo Didactic GmbH & Co. • MPS 21

Please check the adjustment of all sensors and of the mechanical components of

your station to prepare the test of the whole process.

Information

To find out the function and location of the sensors, please use the technical

manual. The inputs can also be checked directly at the PLC-LED´s. To move

pneumatic actuators, please switch off the air-pressure and move them manually by

hand. Please be very careful, move the actuators back before switching on the air-

pressure again. Some pneumatic and the electrical actuators can not be moved in

this way-the pneumatic components can be activated by the manual detection

button on the valve (see picture)

Instructor:show the participants how to find out an input and an output using the

wiring diagrams. Show them why some actuators can not be moved by hand even

without air- and power supply (DC-motors and 5/3-way valves) using the

pneumatic plan to explain. Show them an example how to adjust a sensor to

define the back or front position of a cylinder. Provide the necessary tools.

Deadjust the following sensors and mechanical components (bold)

I/O Station

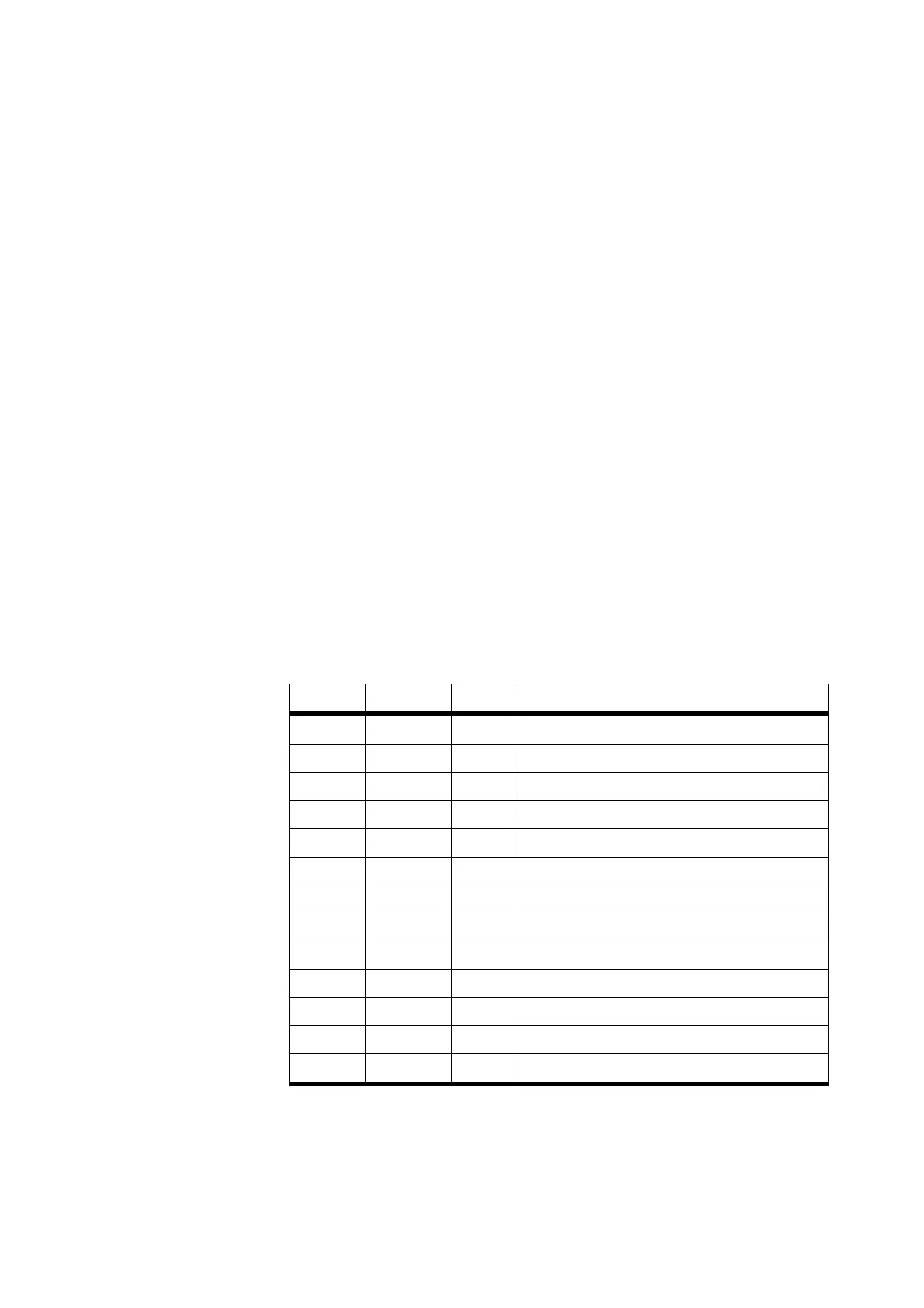

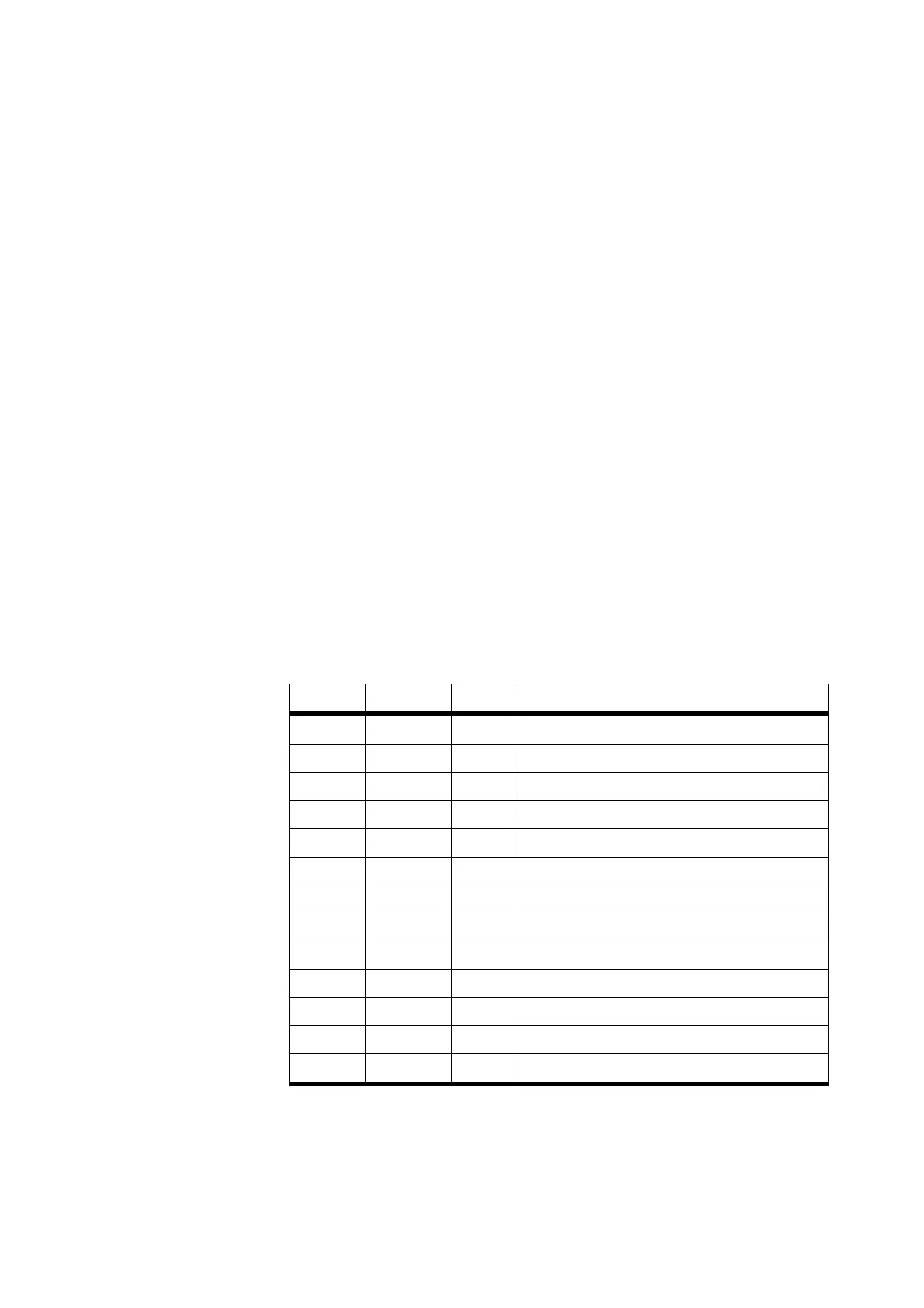

Adress Symbol Ident. Description

I0.0 Part_av Part_AV

Workpiece is available

I0.1 Han_prev 1B1 Handling at previous station

I0.2 Han_foll 1B2 Handling at following station

I0.3 Han_sort 1B3 Handling at sorting position

I0.4 Lift_dow 2B1 Lifting cylinder with gripper is down

I0.5 Lift _up 2B2 Lifting cylinder with gripper is up

I0.6 Sen_mat 3B1 Material detection signal = 0 = black

I0.7 Follow IP_FL Light barrier to the following station

Q0.0 Handprev 1Y1 Solenoid of handling cyl.to previous station

Q0.1 Handfoll 1Y2 Solenoid of handling cyl.to following station

Q0.2 Lifting 2Y1 Solenoid of the lifting cylinder with gripper

Q0.3 Gripper 3Y1 Solenoid of the gripper = 1 = open

Q0.7 Previous IP_N_FO

Light barrier to the previous station

Deadjust the workpiece mounting so that the gripper is not able to pick up the

workpiece centred and close the one-way-flow control valve of the lifting cylinder

to move up.

1.5 Commissioning –

Adjustment of the

Station

Loading...

Loading...