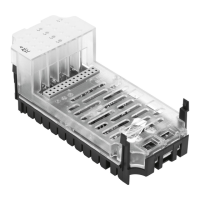

Valve at slot 1

Parameter

set 3

Motion App A Motion App B Motion App C Motion App D Motion App …

System param-

eters

Sys. par. a

Sys. par. b

Sys. par. c

Sys. par. …

Application

parameters

App. par. m App. par. m App. par. m App. par. m App. par. m

App. par. n App. par. n App. par. n App. par. n App. par. n

App. par. o App. par. o App. par. o App. par. o App. par. o

App. par. … App. par. … App. par. … App. par. … App. par. …

Tuning param-

eters

Tun. par. x Tun. par. x Tun. par. x Tun. par. x Tun. par. x

Tun. par. y Tun. par. y Tun. par. y Tun. par. y Tun. par. y

Tun. par. … Tun. par. … Tun. par. … Tun. par. … Tun. par. …

Teach-in data Data record 1 Data record 2 Data record 3 Data record 4 Data record 5

Tab. 38: Example of the structure of parameter set 3

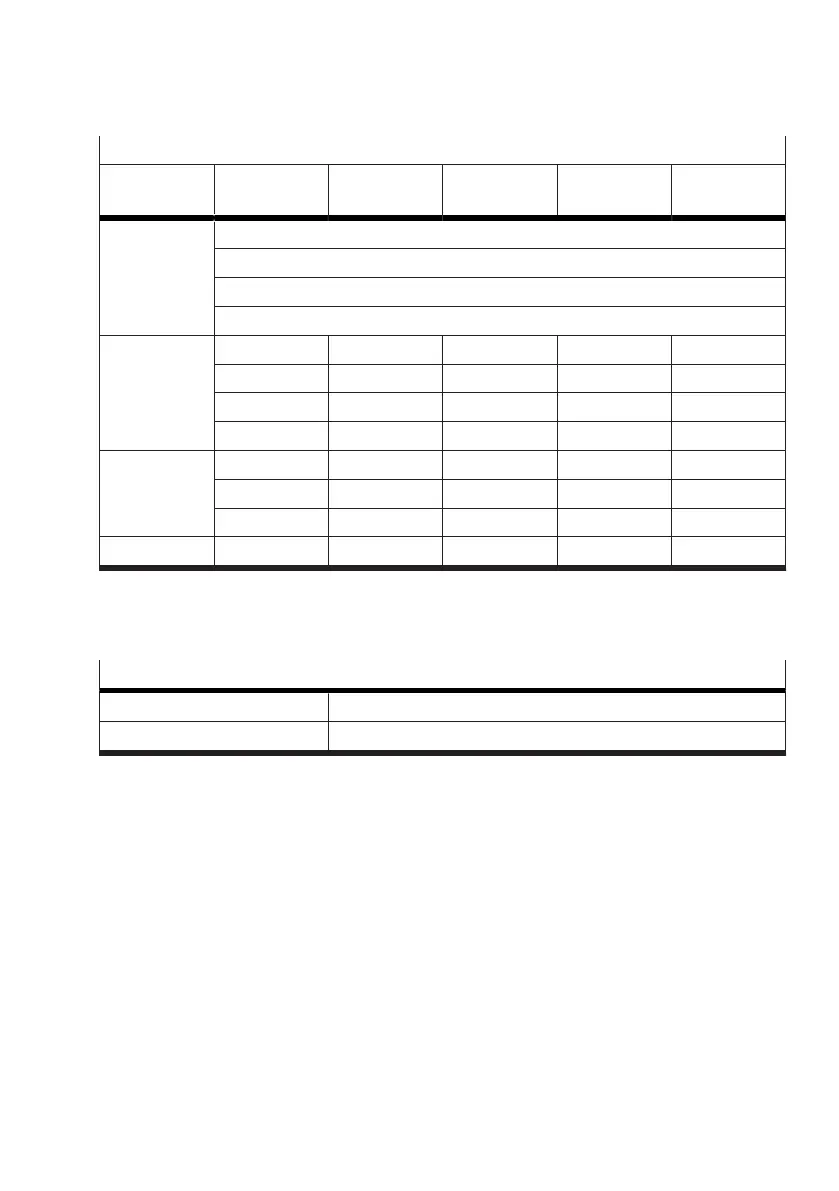

3.4.4

Setpoint and actual values

Setpoint and actual values can be written and read cyclically by the process data.

Setpoint and actual values

Writing setpoint values Output data (PDO, Process Data Output)

Reading actual values Input data (PDI, Process Data Input)

Tab. 39: Setpoint and actual values

The setpoint and actual values are specific to the individual Motion Apps. The structure of the process

data is described in section (

è

3.5 Communication between PLC and Motion Terminal).

3.4.5 Waiting time between Motion Apps

In the following cases, calibration of the associated valve takes place before the Motion App that has

been started is executed:

– Following a restart of the Motion Terminal, a Motion App is started for the first time.

Exception: Motion App #01 in operating mode "controlled"

– After execution of Motion App #01 in operating mode "controlled", Motion App #01 is started for

the first time in the operating mode "regulated" or another Motion App is started.

This calibration can take up to 60 seconds and will be performed automatically prior to execution

of the Motion App. The calibration can be viewed as a return value in the process data

è

Tab. 51

Information on invalid output data.

Loading...

Loading...