48

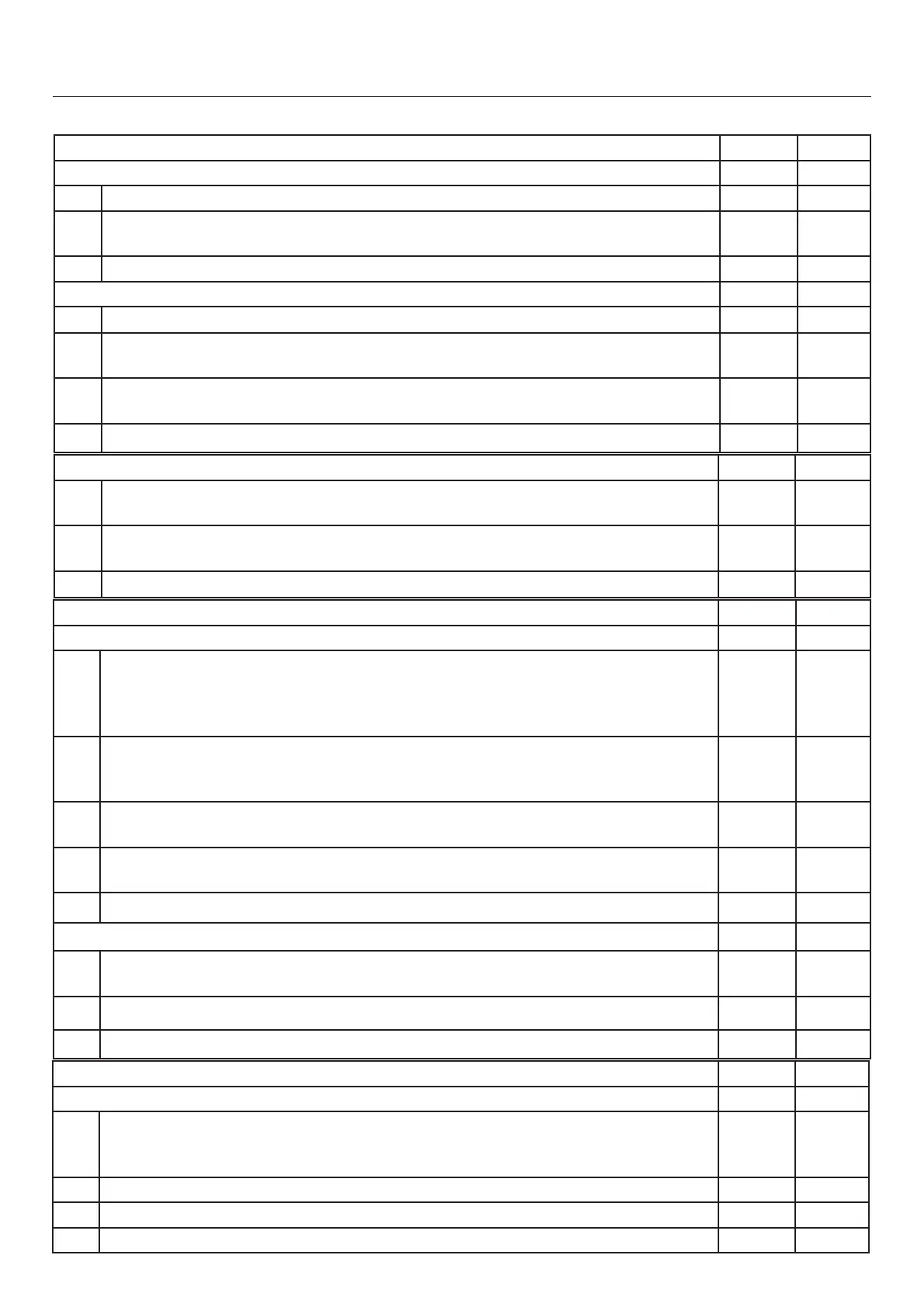

F5X: Lid Faults Yes No

F51: Lid Motor Not Turning/F54: Lid Motor Not Stalling

1 Are there any obstructions within the tub? especially around the edge of the tub

where the lid seals.

Tall utensils placed in the utensil basket can also stop the lid from closing.

Are all the yoke clips securely fastened to the lid?

>>A >>2

2 Is the lid system physically damaged or disconnected. Check for foreign objects that

can cause the lid to jam. Check the side securing tabs are not pushed through the

chassis fouling on the lid yokes.

>>A >>3

3 Check the resistance of each lid motor, only replace a lid motor if it is open or short

circuit. Did this x the fault?

>>A >>4

4 Do the lids move in both upwards and downwards direction in hardware output

diagnostic test mode. This can be done with the drawer open for visibility.

>>A >>5

5 Did this clear the fault and are the lids now operating? >>A >>8

F52: Lid Motor Undercurrent

6 Is the lid motor harness securely and correctly connected? Do the harness

connections at the lid motor show signs of any water damage, corrosion or arcing?

>>A >>7

7 Replace the harness. Does this clear the fault? >>A >>8

8 Replace the motor controller. >>A

F4: Heater Plate Fault Yes No

1 Do the harness connections at the heater plate show any signs of water damage,

corrosion or arcing? If so replace the damaged harness.

>>A >>2

2 Check the resistance of the heating element. Is it outside the spec (refer to section

2.5). If so replace the heating element, does the fault still occur?

>>3 >>A

3 If the fault is still occurring replace the motor controller. >>A

F3X: Over-Temperature Faults Yes No

F30 fault: Invalid Temperature

1 Is the thermistor damaged or disconnected? >>A >>2

2 Measure the resistance of the thermistor ( between pins 1 & 2 of the TEMP connector

on the wash controller). It should be approx 10k Ω at 25

o

C (77

o

F), is it within spec?

>>5 >>3

3 Replace the thermistor. Is the fault still present? >>5 >>A

F31 Fault: Over Temperature

4 Is the incoming water temperature too hot, over 85

o

C (185

o

F) ? >>A >>2

5 Check the heating element resistance on the tub faulting. Is the heating element out

of spec? (refer section 2.5)

>>A >>6

6 Check the element operation in hardware output mode in diagnostics, ll the tub

with 2 litres (1/2 gallon) of water before switching on the element. Is it working OK?

>>A >>7

7 If the fault is still occurring replace the wash controller for the tub faulting. >>A

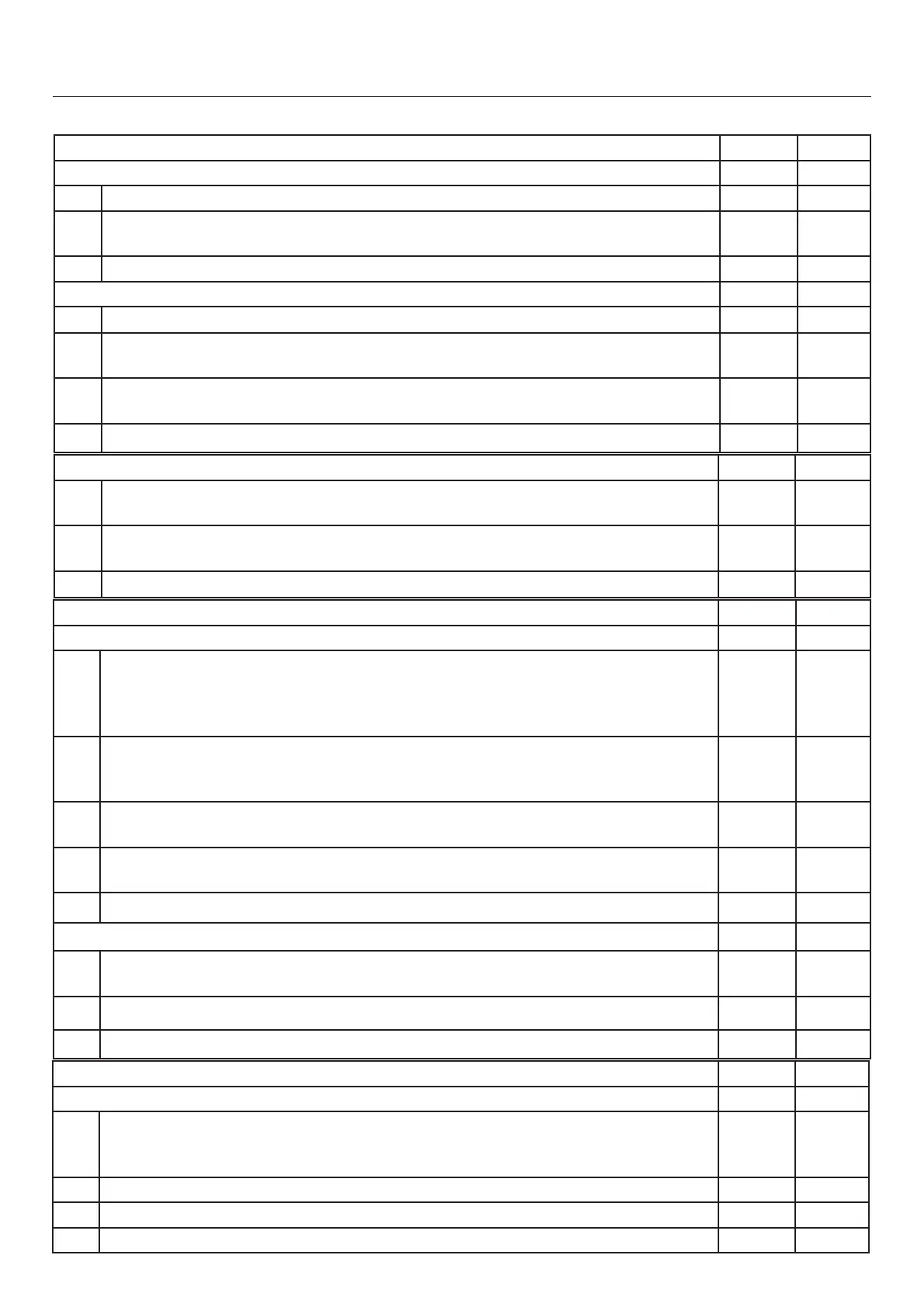

7 FAULT DIAGNOSTICS

F1: Flood Detected Yes No

1 Remove the bottom tub, this will require some force to pull it open, is there water in

the base of the chassis?

>>2 >>9

2 Was there anything in the tubs which obstructed the lid from closing? like large

utensils?

>>3 >>9

3 Make sure the lid system is free from obstructions. Check that the lid system is

operating correctly by entering diagnostic hardware output mode and actuating the

lid motors (Ld). If either of the lid motors fails to actuate correctly, check that the side

installation tab is not obstructing the lid yoke. If there are no obstructions, replace the

lid actuator.

>>A >>4

4 Did the tub overll? If so check the ll valve in diagnostic hardware output mode to

ensure it can turn the water supply on and o.

>>A >>5

5 Is there any foam in the tub? If there is foam, try and determine the cause, i.e. has

liquid detergent been used, or has the customer spilt rinse aid into the tub. Remove

as much foam as possible from the tub and clear the chassis base of water, does this

clear the fault?

>>A >>6

6 Is the motor rotor jammed? can it be turned freely? or is the wash impellor loose on

the motor rotor shaft?

>>A >>7

7 Check for other leak sources. Possible leak sites are the lid seal, seals around the

heater and the wash motor, damaged ll or drain hose or a damaged O-ring where

the drain cu connects to the motor housing. Are any of these damaged or leaking?

>>A >>8

8 Remove the excess water from the chassis base, especially around the ood sensor

area and run the product and check for leaks.

>>A >>9

9 No water in the chassis base, check for corrosion around the ood sensor and ensure

that the ood sensor is correctly positioned and not touching the chassis base.

>>A >>10

10 Replace the main motor controller. >>A

F2X: Motor Faults Yes No

1 Is the harness connected correctly? >>2 >>A

2 Do the harness connections at the motor and motor controller show signs of water

damage, corrosion or arcing? If so replace the damaged harness. Does this clear the

fault?

>>A >>3

3 Check the resistance of the motor coils (8 Ω) 16 Ω phase to phase, are these OK? >>7 >>A

F21: Bridge Over Temperature

4 Is the motor rotor free to turn by hand and is not jammed? If it is jammed remove and

check for obstructions, reassemble and test. Does this clear the fault?

>>A >>9

F24: Motor Stalled/Stopped/Overload

5 Is the motor rotor clear of foreign objects? If not clear the obstruction and test. Does

this clear the fault?

>>A >>9

F25: Motor Loss of Phase

6 Is the motor rotor correctly installed? >>A >>7

7 Replace the motor rotor and run the wash motor in hardware output mode for at

least 10 seconds. Does it operate correctly?

>>A >>8

8 Replace the motor stator assembly and then run the motor rotor again in the wash

direction in hardware output mode. Does it now operate correctly?

>>A >>9

9 Replace the motor controller. >>A

F7X: Fill Valve Faults Yes No

F70: Fill Valve High Current/F71: Fill Valve Low Current

1 Do the harness connections at the ll valve and motor controller show any signs of

water damage, corrosion or arcing. Replace the harness if damaged. Ensure that the

harness is correctly and securely connected. Did this x the fault?

>>A >>2

2 Can you run the ll valve in diagnostic hardware output mode? >>A >>3

3 Replace water valve. Does the fault still occur? >>4 >>A

4 Replace the motor controller. >>A

Loading...

Loading...