Instruction Manual

D103412X012

Detailed Setup—PID Function Block

July 2013

134

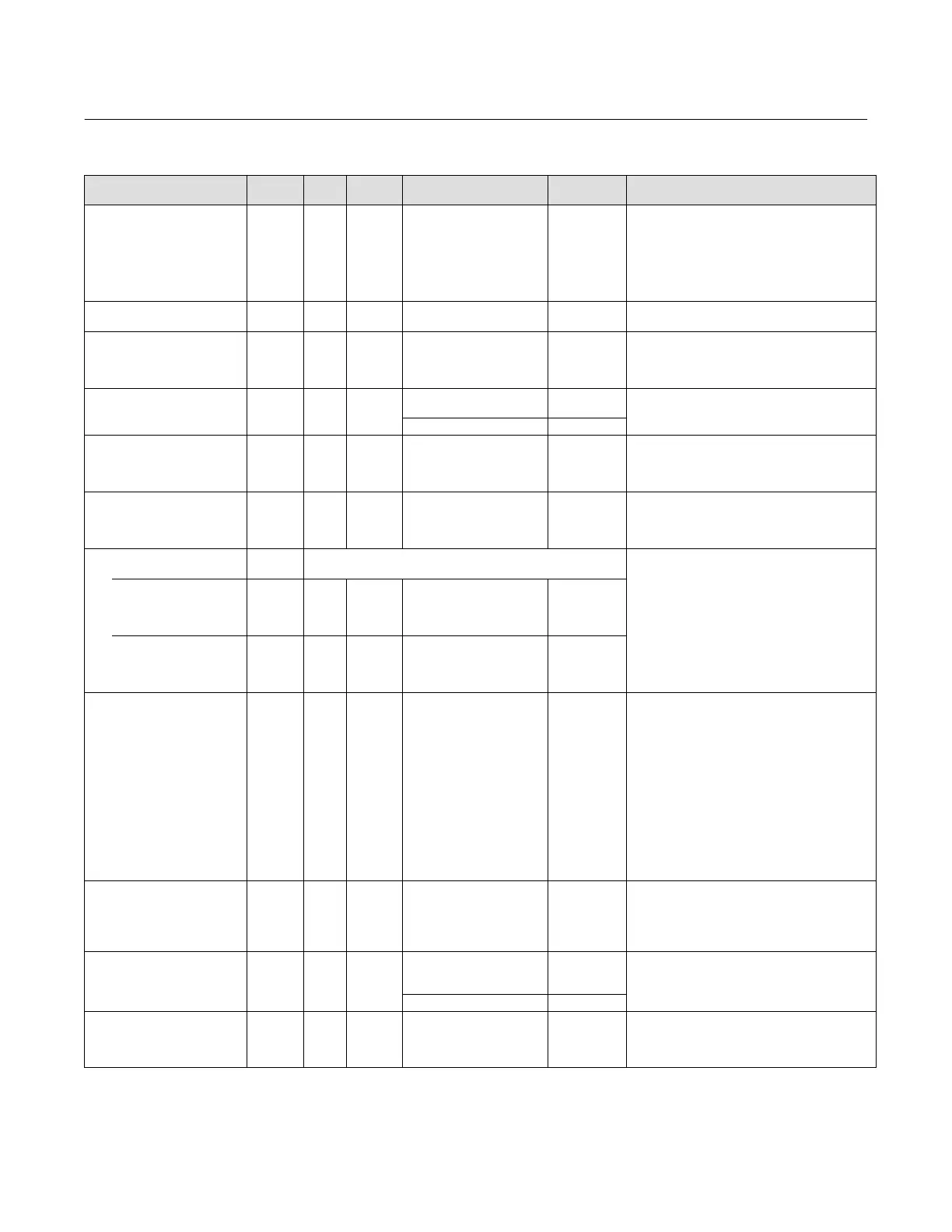

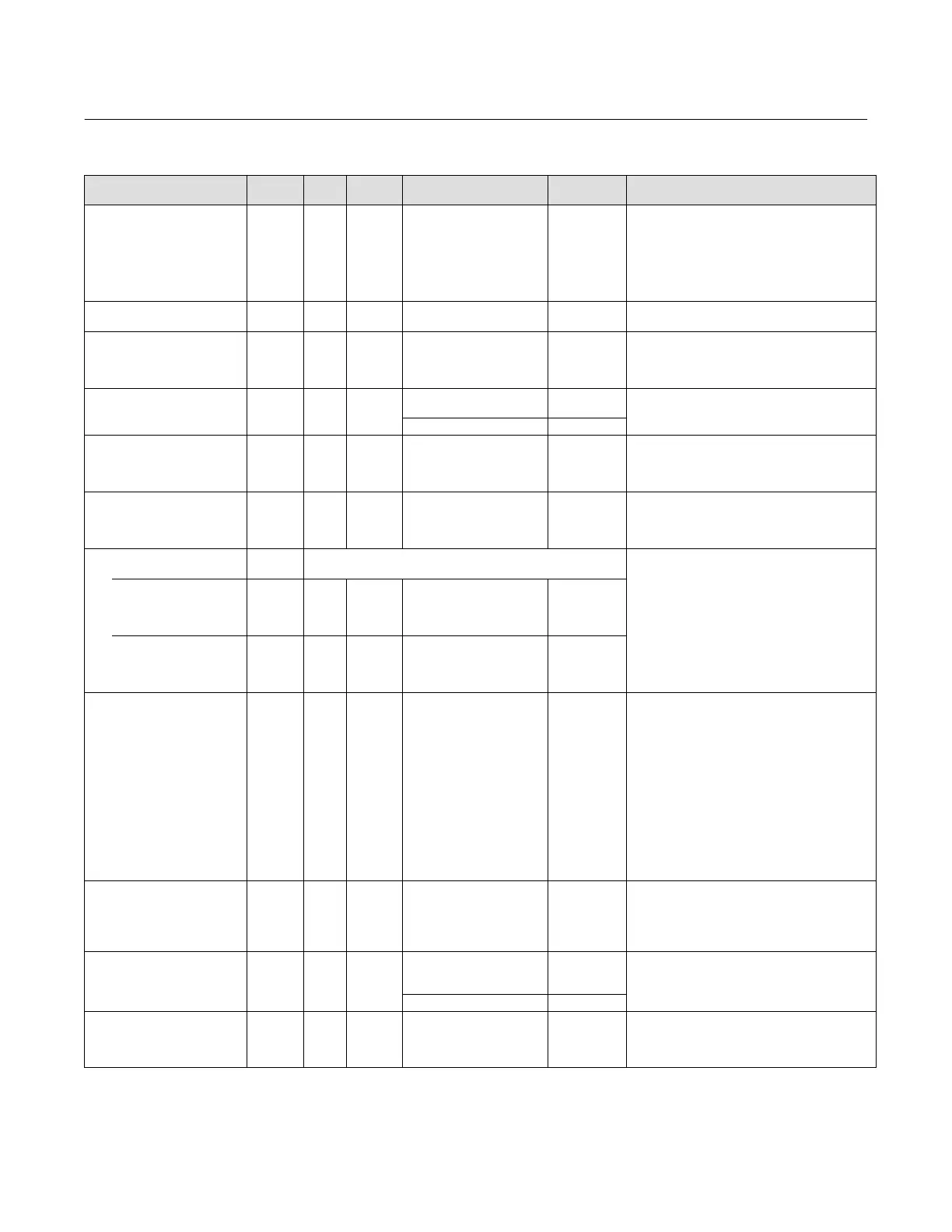

Table 4‐32. PID Function Block System Parameters Definitions (Continued)

DescriptionInitial ValueRange

Block

Mode

RO /

RW

Index

Number

Label

PARAMETER_NAME

Block Error

BLOCK_ERR

6 RO N/A

Defined Bits

1: Block Configuration Error

4: Local Override

7: Input Failure/ Bad PV status

14: Power‐up

15: Out‐of‐Service

Dynamic

Data Type: Bit String

0 = inactive

1 = active

This parameter reflects the error status associated

with the hardware or software components

associated with a block. It is a bit string so that

multiple errors may be shown.

Process Value

PV

7 RO N/A Dynamic

Data Type: DS‐65

The process variable used in block execution.

Setpoint

SP

8

OOS

MAN

AUTO

PV_SCALE +/- 10% Dynamic

Data Type: DS‐65

The target block setpoint value. It is the result of

setpoint limiting and setpoint rate of change

limiting.

Output

OUT

9

MAN

OOS

Status

OUT_SCALE +/- 10%

Dynamic

DS‐65

The block output value and status.

Value

Process Value Scale

PV_SCALE

10 OOS

EU at 100%

EU at 0%

Units index

Decimal

Point

100

0

%

2

Data Type: DS‐68

The high and low scale values, engineering units

code, and number of digits to the right of the

decimal point associated with PV.

Output Scale

OUT_SCALE

11 OOS

EU at 100%

EU at 0%t

Units index

Decimal

Point

100

0

%

2

Data Type: DS‐68

The high and low scale values, engineering units

code, and number of digits to the right of the

decimal point associated with OUT.

Grant Deny

GRANT_DENY

12

Data Type: DS‐70

Options for controlling access of host computers

and local control panels to operating, tuning, and

alarm parameters of the block. Not used by the

device.

GRANT: 0=N/A, 1=granted

DENY: 0 = N/A, 1= denied

GRANT 12.1 ALL

0: Program

1: Tune

2: Alarm

3: Local

All bits: 0

DENY 12.2 ALL

0: Program

1: Tune

2: Alarm

3: Local

All bits: 0

Control Options

CONTROL_OPTS

13 OOS

0: Bypass Enable

1: SP tracks PV in MAN

2: SP tracks PV in ROUT

3: SP tracks PV in LO or MAN

4: SP tracks RCAS or CAS in

IMAN, LO, MAN or ROUT

5: Direct Acting

7: Track Enable

8: Track in Manual

9: Use PV for BKCAL_OUT

10: Act on IR

12: Restrict SP to limits in

Cas and RCas

13: No output limits in MAN

All bits: 0

Data Type: Bit String

0=disable

1=enable

Allows you to specify control strategy options.

Status Options

STATUS_OPTS

14 OOS

0: IFS (Initiate Fault State)

if BAD IN

1: IFS if BAD CAS_IN

2: Use Uncertain as Good

5: Target to MAN if BAD IN

All bits: 0

Data Type: Bit String

0=disable

1=enable

Allows you to select options for status handling

and processing.

Input

IN

15 ALL

Status

BAD:

NC:

const

Data Type: DS‐65

The primary input value of the block.

Value 0

Process Value Filter Time

PV_FTIME

16 ALL Positive 0

Data Type: Float

The time constant of the first-order PV filter. It is

the time, in seconds, required for a 63 percent

change in the IN value.

-Continued-

Loading...

Loading...