TemplateA4_v20130506

14

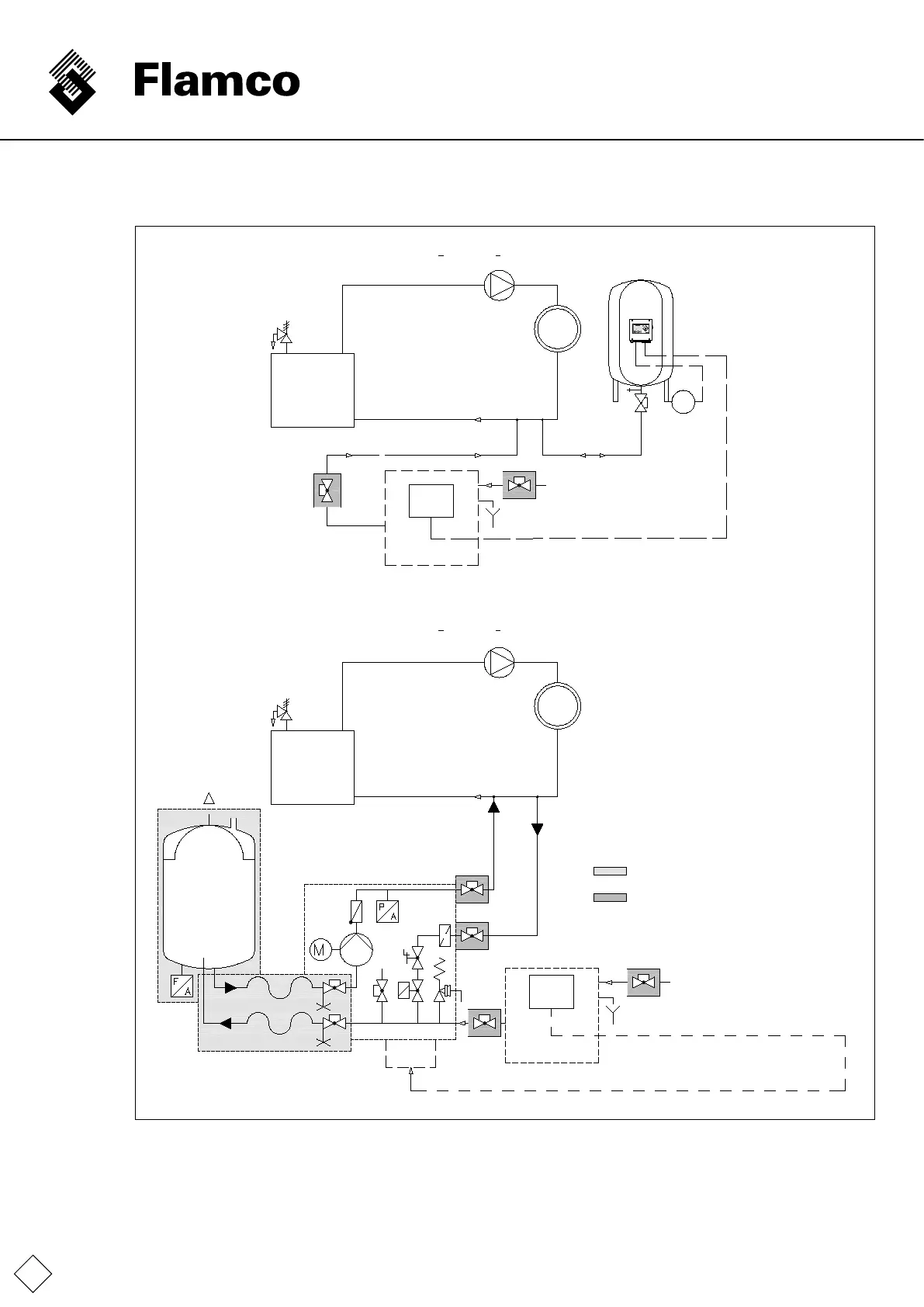

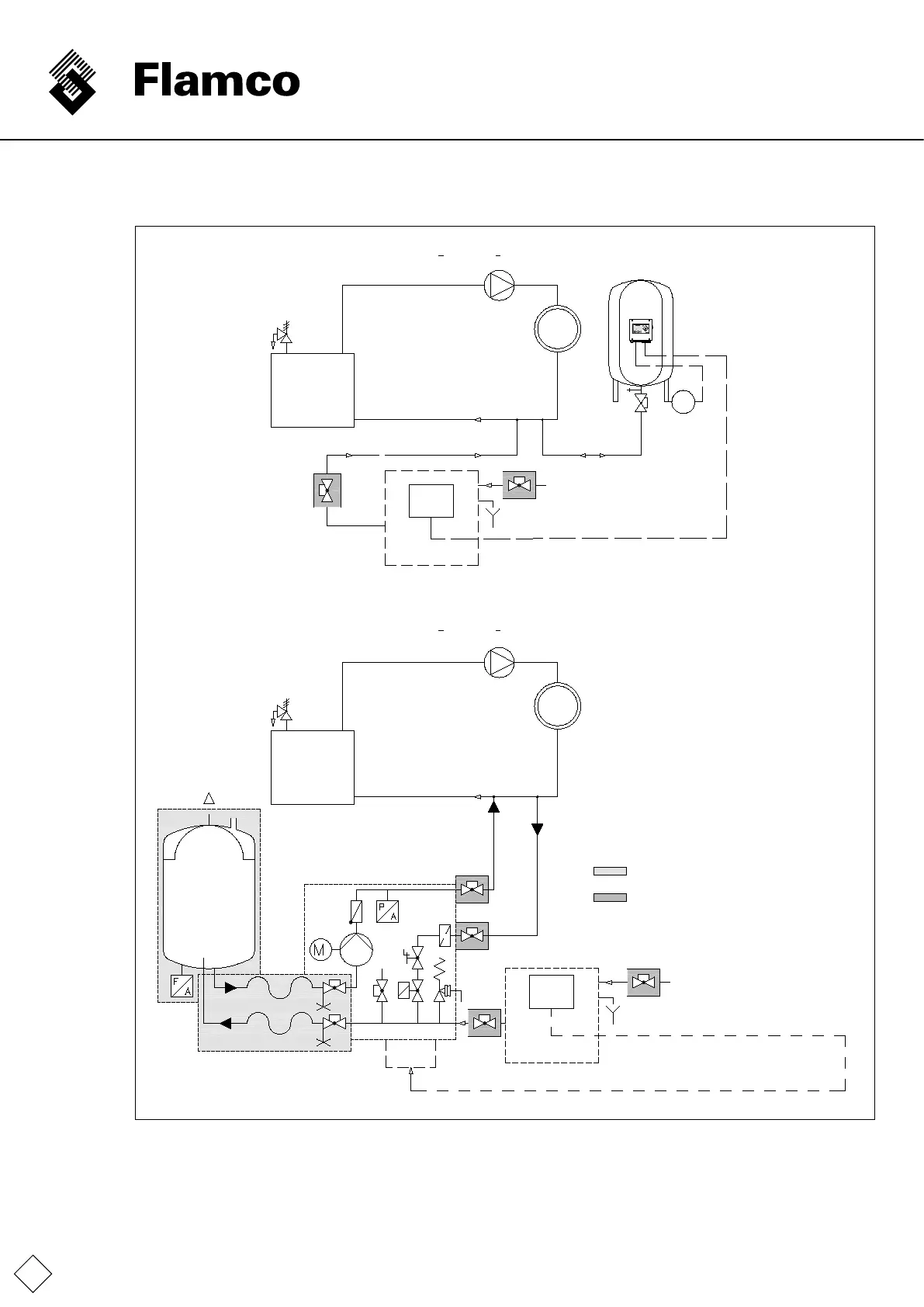

1.3 Sample installation diagram

M -K

L

F la m c o -F I L L P

DN *

F la m c o -F I L L P

*

**

Supply temperature <105°C(STB<110°C)

Supply temperature <105°C(STB<110°C)

Example of level-

controlledllingwitha

Flamco-Fill P on a

Flexcon MK

Example of

level-controlled

llingwitha

Flamco-Fill P on a

Flexcon MK

Please note: If the

return line is routed horizontally, implement the

connectionfromabove(notfrombelow)toavoid

additional contamination

.

To be provided by the customer: System inlet,

system outlet,

llinginlet,componentcouplings.

Control unit

PLC

Terminal(8,9);33,34;18,19,20asperPLC

Filling water inlet

Coupling assembly *

Basic vessel*

System supply

side

System supply

side

Control module Flamcomat *

Cap valve**

Cap valve**

Scope of supply, standard.

Accessories

Compressor

pressure maintenance

unit with

PLC control

Heater

Heater

Terminal

box

Terminal

box

Filling water inlet

Terminal(8,9);33,34;18,19,20asperPLC

Hot leg

Hot leg

Cold leg

Cold leg

Loading...

Loading...