When using the sighting tool for pipes that are 10” and less, use the measurement from the

special tool as described in section 5.3.1 to find the correct depth for the transducer. This

depth should be the same for the sighting tool. Measure from the narrow end of the sighting

tool and tighten the stop washer at that position. Insert the sighting tool so that the stop

washer is flush with the flange on the transducer holder, this is shown in Figure 18. There is

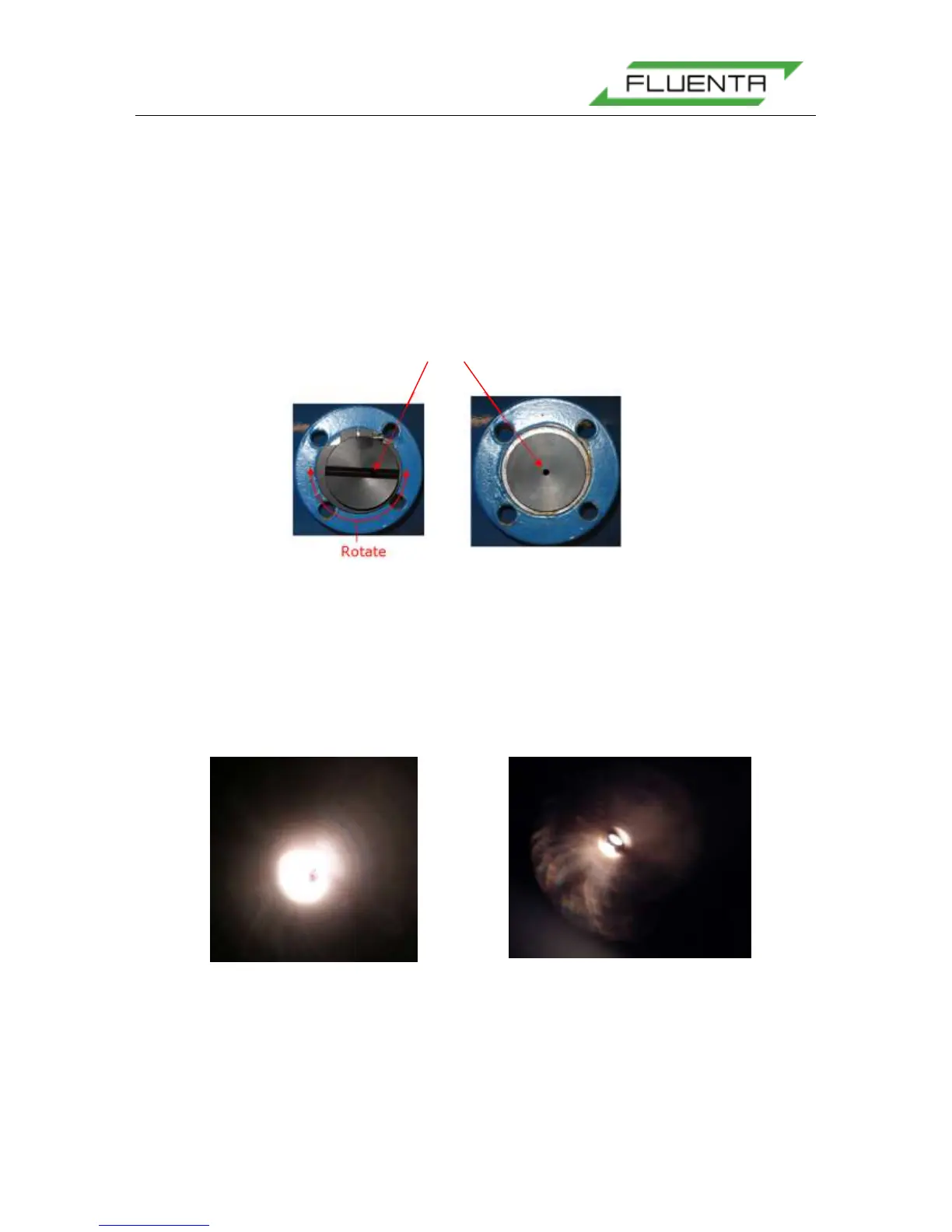

a groove in the head of this type of sighting tool shown in Figure 19. Align one sighting tool

with the pipe, and rotate the other until the light is visible. Adjust the sensor holder so that the

circle of light is seen as described below.

Figure 19: Look through the holes on the sighting tool. Rotate the sighting tool on the left to

get a correct alignment.

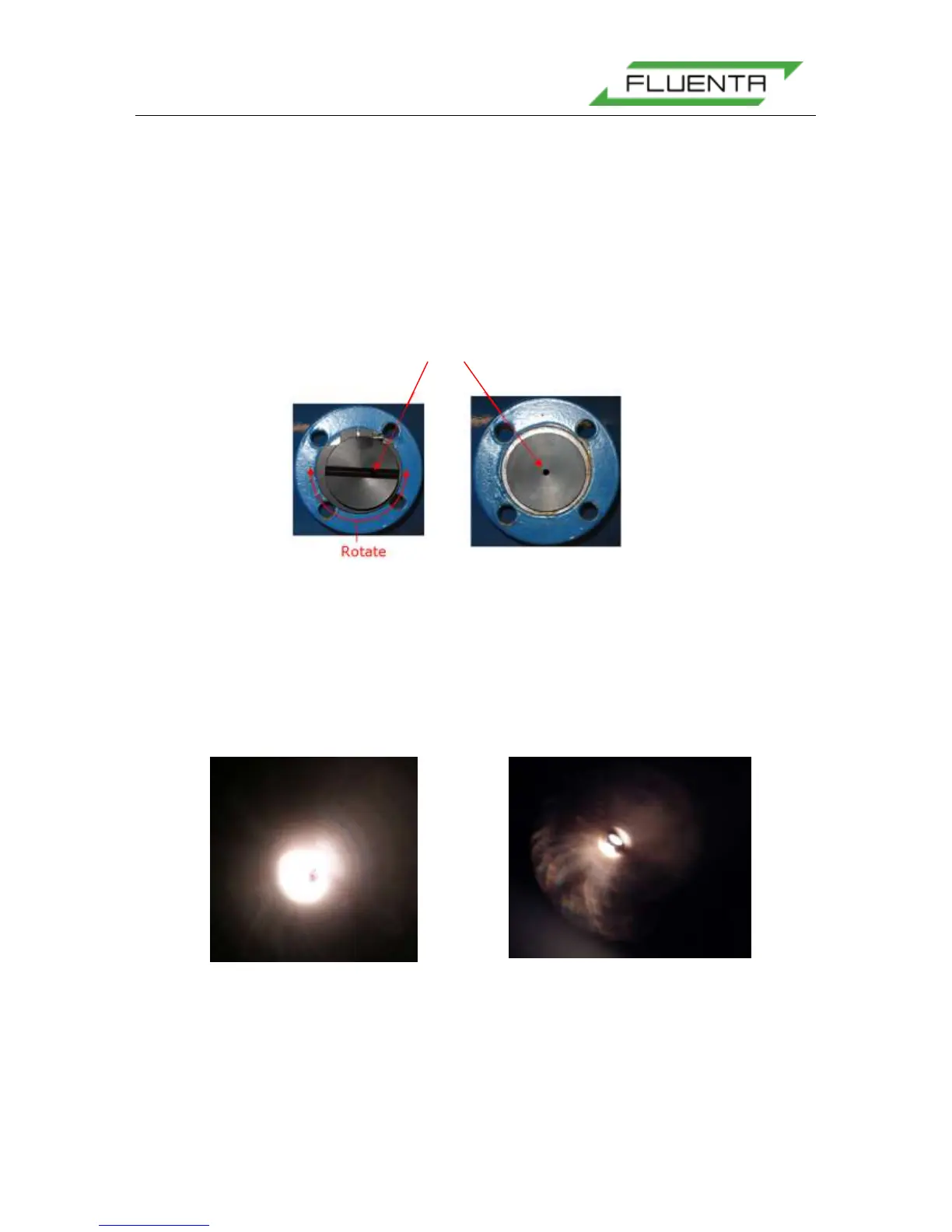

When the transducer holders are properly aligned and the sighting tools are inserted, it is

possible to see a perfect circle of light when looking through the hole in one of the sighting

tools, shown in Figure 20. If there is not enough ambient light, it may be necessary to shine a

light source through the hole in the opposite sighting tool.

5.2.4 Hot Tapping Transducers Full Size, TFS

If hot tapping is needed, use the same procedure as described in “Cold Tapping” but do not

drill the pilot holes. When the welding of the transducer holders has been performed and the

ball valves are mounted, connect the hot-tapping equipment to the 2" ball valve. Open the

Visual check

Loading...

Loading...