4.3 Equipment Information

The FGM 160 requires +24 VDC power supply (nominal). If 24 VDC is not available,

an optional 110-230 VAC/24 VDC converter can be supplied by Fluenta.

For more detailed equipment information and equipment ratings, please refer to: FGM 160 –

Hazardous Area Installation Guidelines[1].

4.4 Manufacturer Information

The FGM 160 Flare Gas Meter is manufactured by Fluenta AS:

5. TRANSDUCER/PROBE INSTALLATION

5.1 Installation of Transducer Holders

There are three alternatives for mounting the transducer holders. The first uses a metering

spool piece that has the transducer, pressure, and temperature holders already installed.

The second is referred to as “Cold Tapping”, where the holders are installed on a section

of pipe that is shut off from the flare system. The third option is referred to as “Hot Tapping”,

where the holders are mounted onto a flare pipe that is active. The metering spool piece is

assembled in a mechanical workshop, and “Cold Tapping” and “Hot Tapping” are done by

welders under the supervision of Fluenta personnel.

It is recommended that all of the above three methods are performed under Fluenta

supervision, including spool piece inspection and welding supervision.

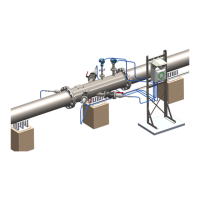

5.1.1 Space Requirements

The space requirements around the pipe vary depending on transducer models and pipe

diameters. This will be covered in the following sections. The transducers must be mounted,

regardless of the pipe diameter or transducer model, on a straight section of pipe. The length

of this straight section must be at least 15 times the diameter of the pipe. The nearest

upstream disturbance must be at least 10 times the diameter of the pipe away from the

center of the metering section, and the nearest downstream disturbance must be at least 5

times the diameter of the pipe long. These distances are illustrated in Figure 1. For

installations that cannot meet these requirements, Fluenta should be contacted as this may

have an effect on the measurement uncertainty. As this product is a fiscal measurement

system, this effect should be evaluated.

Loading...

Loading...