User Manual F012-P

Page 50 FW_F012-P_M_v0501-01_EN

APPENDIX B - TROUBLESHOOTING

Table 1 lists and describes how to troubleshoot problems that can occur when installing or operating

the F012-P.

Table 2 lists internal alarm codes and conditions signaled by a blinking ALARM flag on the display

(

). Press the SELECT key several times to display the 4-digit error code shown in Table 2.

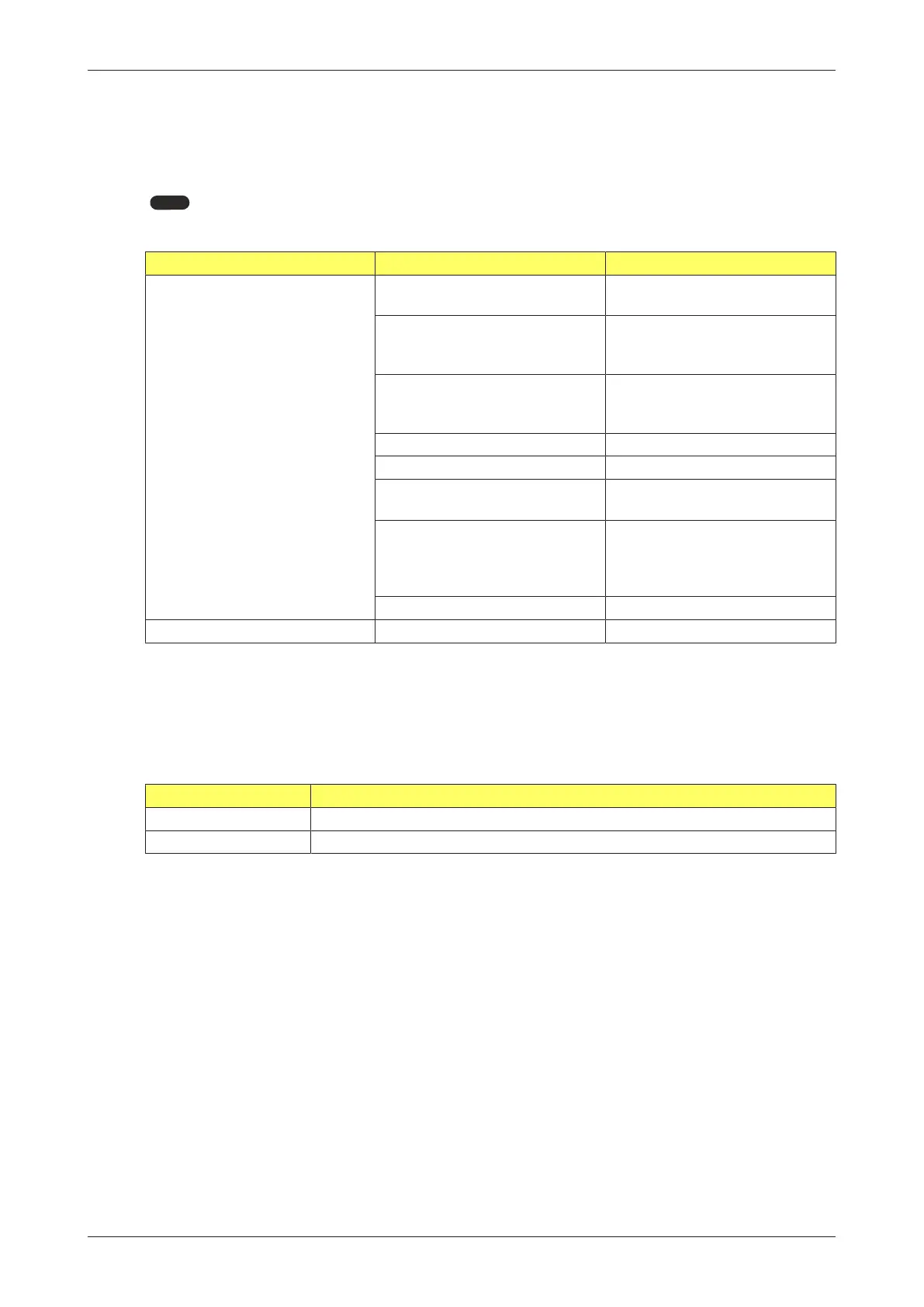

Table 1: Install and configuration errors

Observation Possible cause Check

No flow is detected while there

is flow

Wrong signal selection in

SETUP menu

5.1: FLOWMETER > SIGNAL

Unit or Time unit not matching

flow

2.1: FLOW RATE > UNIT

2.2: FLOW RATE > TIME UNIT

2.3: FLOW RATE > DECIMALS

K-factor setting wrong 2.4: FLOW RATE > K-FACTOR

2.5: FLOW RATE > DECIMALS K-

FACTOR

Calculation window too big 2.6: FLOW RATE > CALCULATION

Cut-off period wrong 2.7: FLOW RATE > CUT-OFF

LCD update period too long 4.1: POWER MANAGEMENT > LCD

UPDATE

Electrical connections wrong

Note: sensor input connectors

depend on Type

Terminals 1-3 (6): flowmeter

input[»28]

Terminals 5-7: flowmeter

input[»33]

Sensor not working properly Sensor

Pass code is unknown Call your supplier

An ALARM condition will in most cases be handled internally. If all programmed and measured

values appear to be correct, intervention by the Operator is not necessary.

If an ALARM occurs more often or stays active for a longer period, please contact your supplier.

When multiple alarms occur, the error code shown is the sum of the error codes as given below. For

example 0003 is a combination of error code 0001 and 0002.

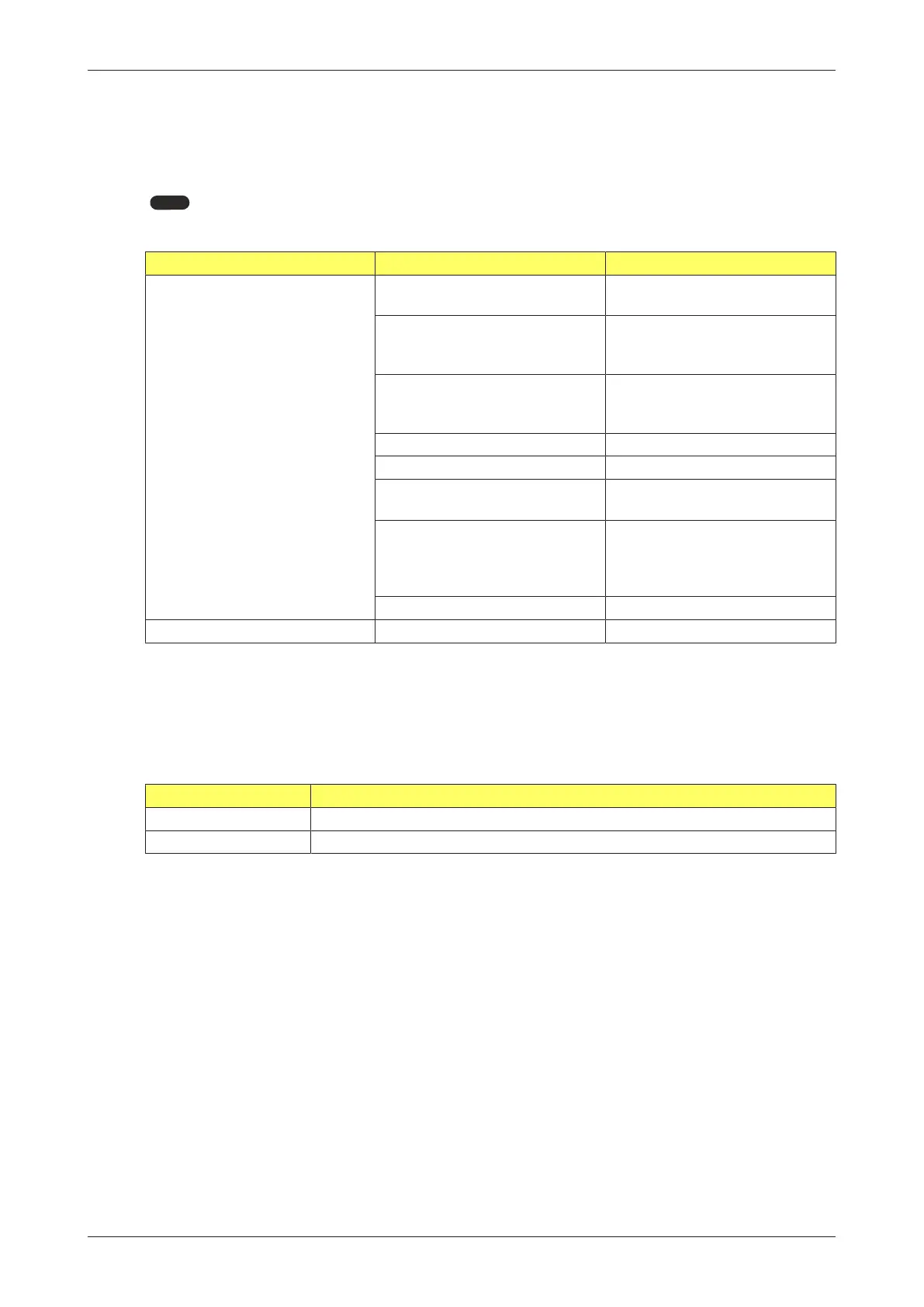

Table 2: Internal alarms

Alarm Explanation

0001 Display error - Data on display might be corrupt

0002 Data storage error - Programming cycle might have gone wrong

Loading...

Loading...