Process Calibrators

Verification

31

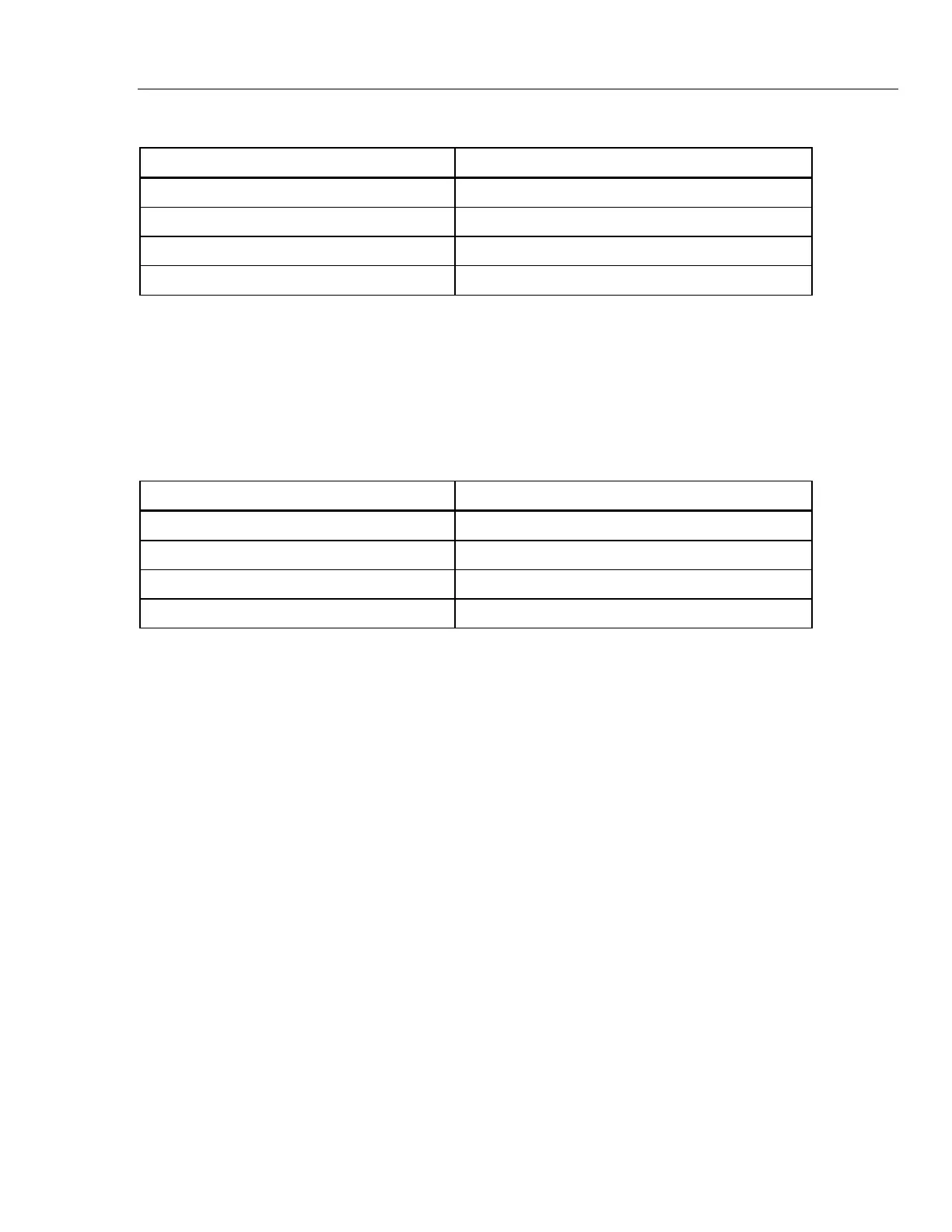

Table 41. 712 Verification Resistance Values

5520A Outputs (Ω) 4-wire 712 Readings (Ω)

5.00 4.899 to 5.101

300.00 299.825 to 300.175

1500.0 1499.525 to 1500.475

30000.0 2999.15 to 3000.85

11. Make 2-wire connections on the 712 to 4-wire connections on the Fluke 8508A. Set

the Fluke 8508A to measure 4-wire resistance.

12. Press I until OUTPUT is displayed.

13. Set the 712 to output the resistance values in Table 42. Verify that the Fluke 8508A

readings are within the limits shown.

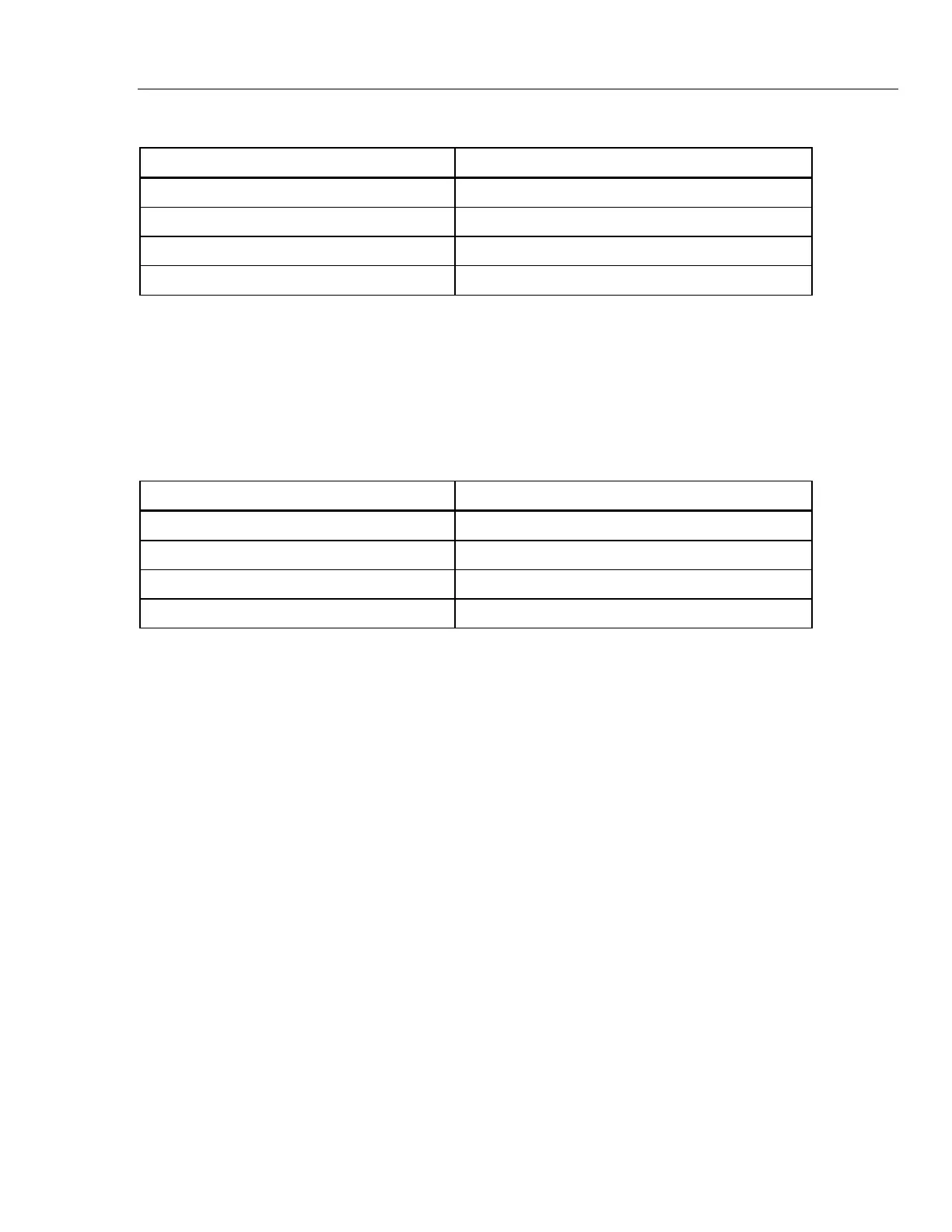

Table 42. 712 Verification Outputs

712 Outputs (Ohms) Fluke 8508A Readings (Ohms)

5.00 4.899 to 5.101

300.00 299.825 to 300.175

1500.0 1499.525 to 1500.475

30000.0 2999.15 to 3000.85

14. Disconnect all connections to the 712. The 712 verification test is complete.

713 Verification

Pressure Verification

1. Carefully attach the pressure fitting of the deadweight tester to the pressure port of

the 713 Calibrator.

Note

The use of TEFLON tape at the pressure fitting strengthens the seal.

2. Press the green O key to turn the 713 on.

3. The display should read 0.00 PSI with the deadweight tester opened up to ambient

air. If not, press the

Z key until display does read 0.00 PSI.

4. Depending if the instrument being tested is a 713 30G or a 713 100G, set up the

deadweight tester for the sequence of PSI inputs from Table 43 to be injected into the

pressure port of the 713 Calibrator.

5. Ensure the pressure has stabilized at each input before verifying the display reading.

6. Carefully vent all pressure and disconnect the 713 from the deadweight tester.

Loading...

Loading...