Process Calibrators

Verification

49

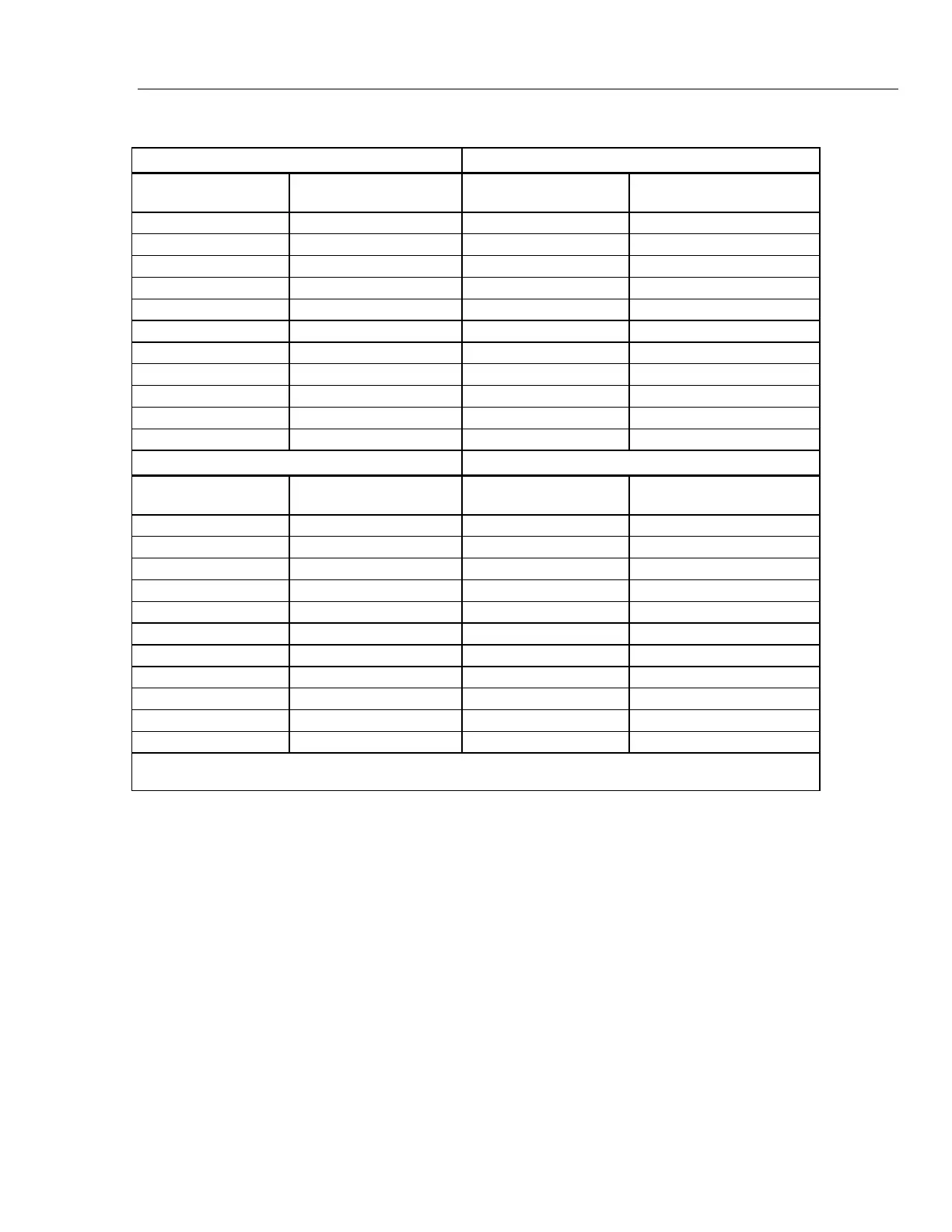

Table 68. 718 and 718Ex Pressure Verification

718 and 718Ex 1G 718 and 718Ex 30G

Input

Pressure

Display

Reading

Input

Pressure

Display

Reading

0 psi 0.0005 to -0.0005 0 psi -0.015 to 0.015

0.2 psi 0.2005 to 0.1995 6 psi 5.985 to 6.015

0.4 psi 0.4005 to 0.3995 12 psi 11.985 to 12.015

0.6 psi 0.6005 to 0.5995 18 psi 17.985 to 18.015

0.8 psi 0.8005 to 0.7995 24 psi 23.985 to 24.015

1 psi 1.0005 to 0.9995 30 psi 29.985 to 30.015

0.8 psi 0.8005 to 0.7995 24 psi 23.985 to 24.015

0.6 psi 0.6005 to 0.5995 18 psi 17.985 to 18.015

0.4 psi 0.4005 to 0.3995 12 psi 11.985 to 12.015

0.2 psi 0.2005 to 0.1995 6 psi 5.985 to 6.015

-1 psi -0.9995 to -1.0005 -12 psi * -12.015 to -11.985

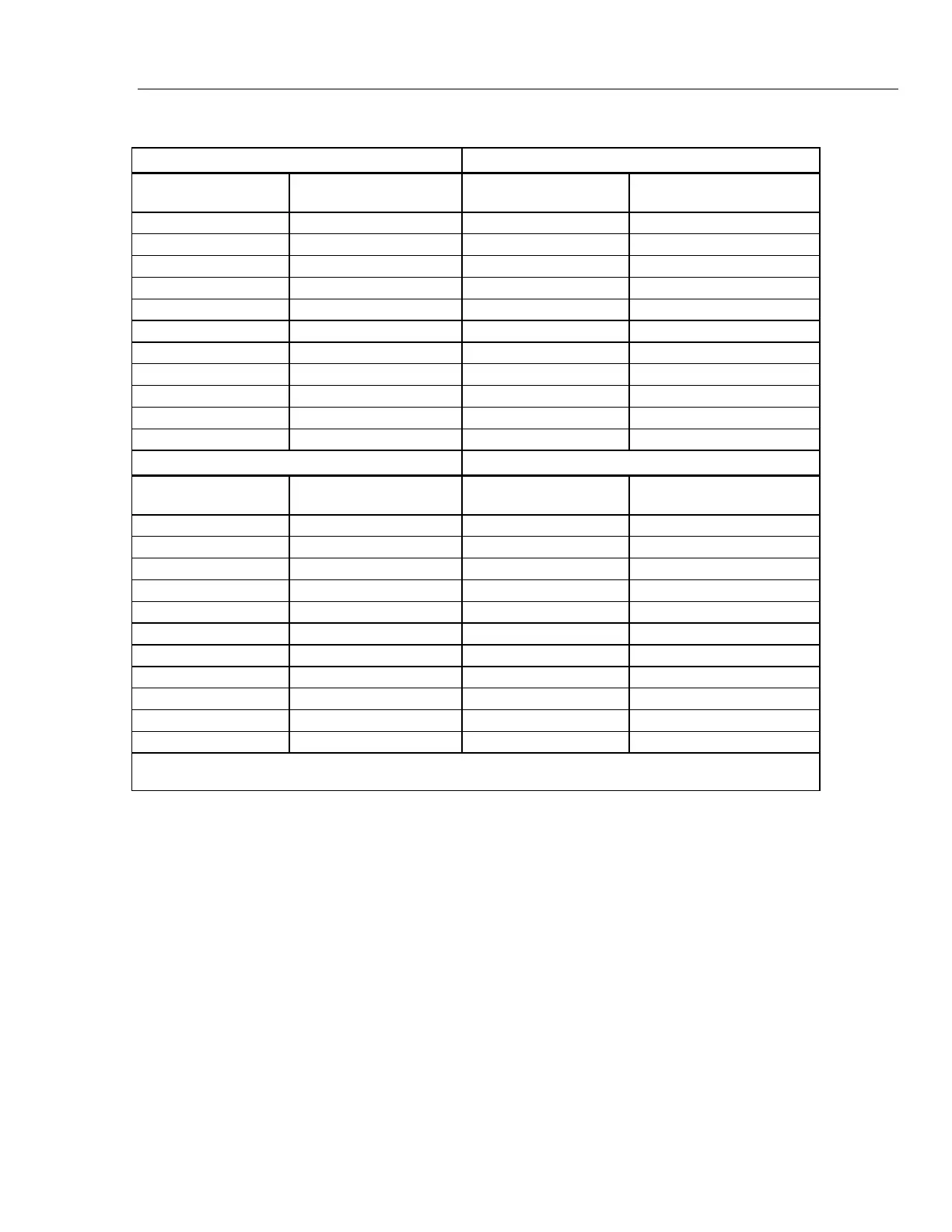

718 and 718Ex 100G 718 and 718Ex 300G

Input

Pressure

Display

Reading

Input

Pressure

Display

Reading

0 psi -0.05 to 0.05 0 psi 0.15 to -0.15

20 psi 19.95 to 20.05 60 psi 60.15 to 59.85

40 psi 39.95 to 40.05 120 psi 120.15 to 119.85

60 psi 59.95 to 60.05 180 psi 180.15 to 179.85

80 psi 79.95 to 80.05 240 psi 240.15 to 239.85

100 psi 99.95 to 100.05 300 psi 300.15 to 299.85

80 psi 79.95 to 80.05 240 psi 240.15 to 239.85

60 psi 59.95 to 60.05 180 psi 180.15 to 179.85

40 psi 39.95 to 40.05 120 psi 120.15 to 119.85

20 psi 19.95 to 20.05 60 psi 60.15 to 59.85

* -12 psi -12.05 to -11.95 -12 psi -11.85 to -12.15

*Vacuum is only specified for V1.3 and later. To display the firmware version, start with the 717 off, press

and hold M, then press the power button.

Leak Test Verification

1. Seal off the pressure sensor input port.

2. Using the fine adjust knob, pressure-vacuum switch and internal pump, set the

calibrator to (approximately) the values in Table 69. Let the unit sit for one minute,

then record the displayed value.

3. Wait for one more minute, then record a second reading. The difference between the

first and the second reading is the leak rate.

Loading...

Loading...