Operation

Introduction

3

3-3

Introduction

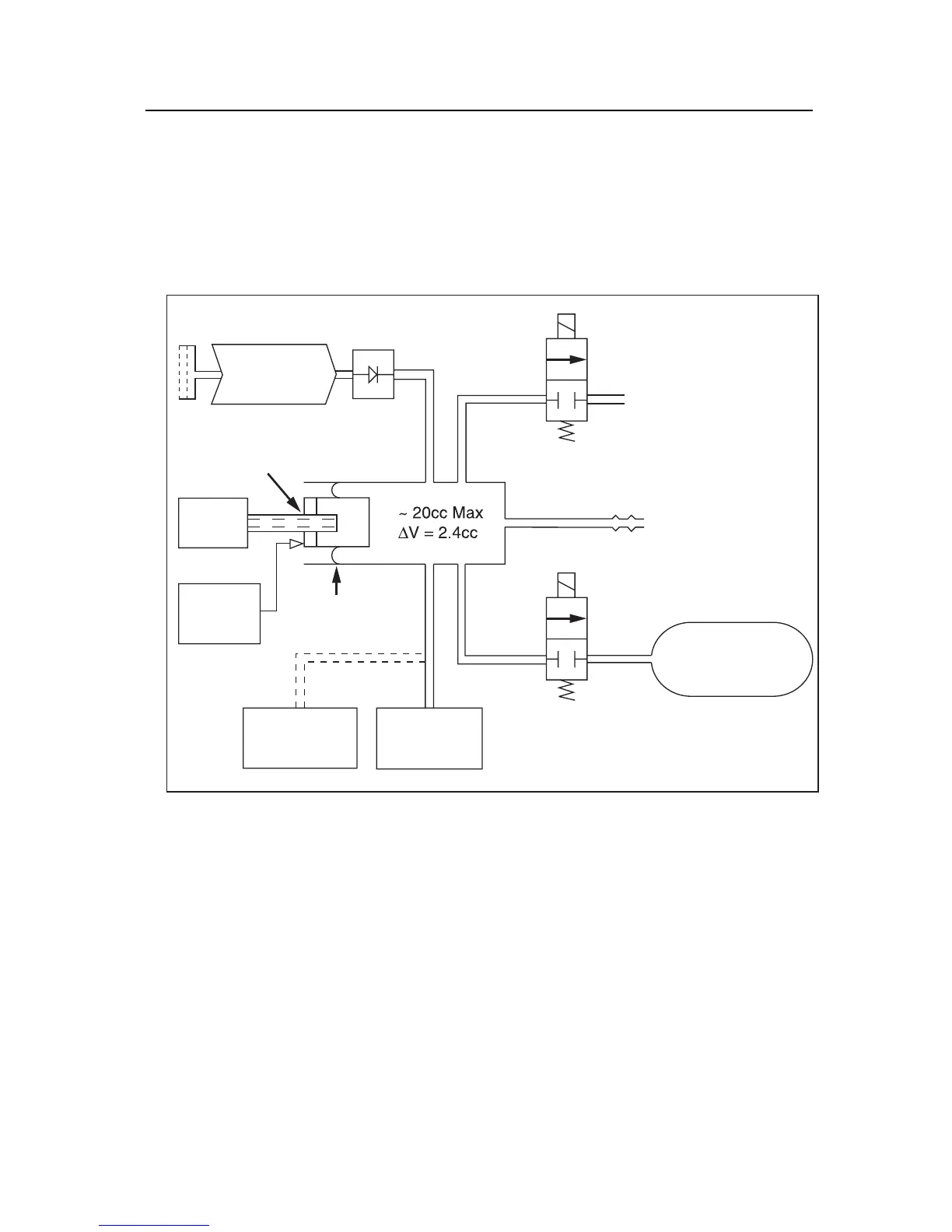

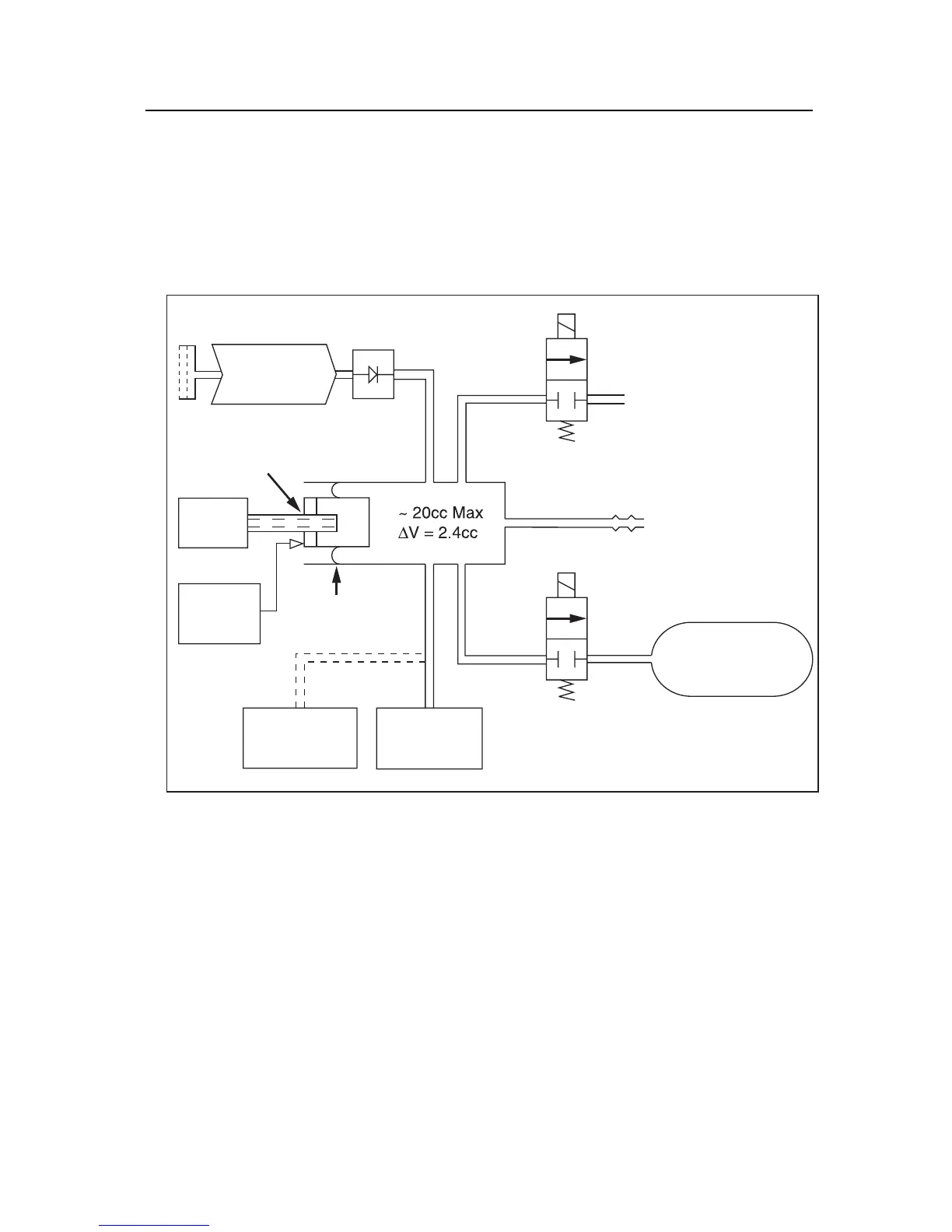

The Tester contains a microprocessor that reads and controls the front panel

keyboard, the display, serial port, printer port, a diaphragm pump, two solenoid

valves, a step motor, a position sensor, and a pressure transducer (Figure 3-1).

Filter

Step

Motor

Home

Position

Sensor

Lead Screw

and Piston

Option

Rolling

Seal

Ring Stud

N.C. Solenoid

Valve

Front Panel

Pressure Port

Vent/Zero Port

Internal Adult

Cuff Volume

290cc

12

Ring

Stud

N.C. Solenoid

Valve

12

Hi Accuracy

Pressure

Sensor

Standard

Pressure

Transducer

Check Valve

DC

Diaphragm

Pump

fas14.eps

Figure 3-1. Tester Pneumatic Block Diagram

The diaphragm pump is used as a pressure source for the relief valve, leak, and

pressure source tests. The diaphragm pump pulls air through a filter and forces it

through a check valve into the main manifold of the instrument. This main

manifold has an internal volume of approximately 20 cc and is directly connected

to the pressure port on the front panel. Pressure in the manifold is measured by a

pressure transducer and can be released by a solenoid-operated valve. The volume

of the main manifold can be increased by approximately 290 cc, to simulate an

adult pressure cuff, by opening a second solenoid valve.

A stepper motor and lead screw move a piston into the manifold to decrease the

manifold volume, thereby creating pressure pulses to simulate a human subject. A

seal around the piston is maintained by a rolling diaphragm seal. The size and

Loading...

Loading...