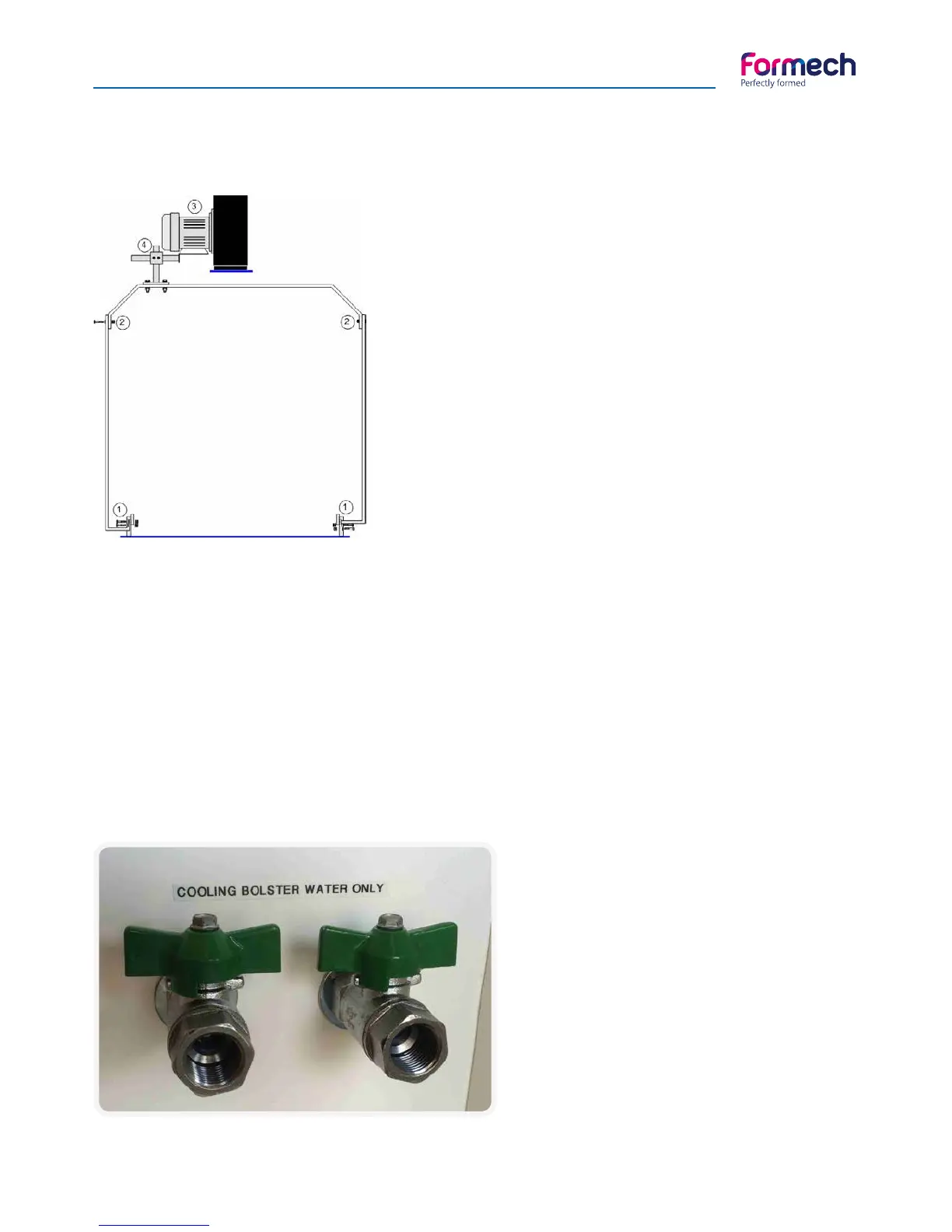

A- Attaching the cooling system

1- Fit the gantry sides to the two heater rails at the boltholes on

either side of the moulding area with the four nuts and screws

supplied.

2- Fit the Gantry cross member to the top of the gantry sides

with the four nuts and bolts supplied. Mount the fan on the cross

member post so that the fan may be positioned behind the

cross member directing the fan draft forward and away from the

heater.

3- The swivel block is supplied fitted to the fan unit. Slide this onto

the cross member post and tighten the grub screws and locking

nuts. Never fit the fan posts on the underside of the cross member

as the fan may fall and cause injury. Mounting of the fans is a 2

person operation.

4- Adjust the fan unit to the required position and tighten all

the grub screws and lock nuts. Insert her cable into the clips on

the gantry and route the cable down to the fan socket on the

electrical box.

Optional - Cooling system

B- Operating the cooling system

The corresponding FAN button on the touch screen will operate the cooling fan at the appropriate time to

cool the moulding. The button changes colour when operated ON/OFF. It is worth considering the position

of the fan mounting to achieve good and consistent results with different mouldings.

Directing the airflow from behind the cross member down towards the centre of the moulding will reduce

the cooling effect of the fan on the heater.

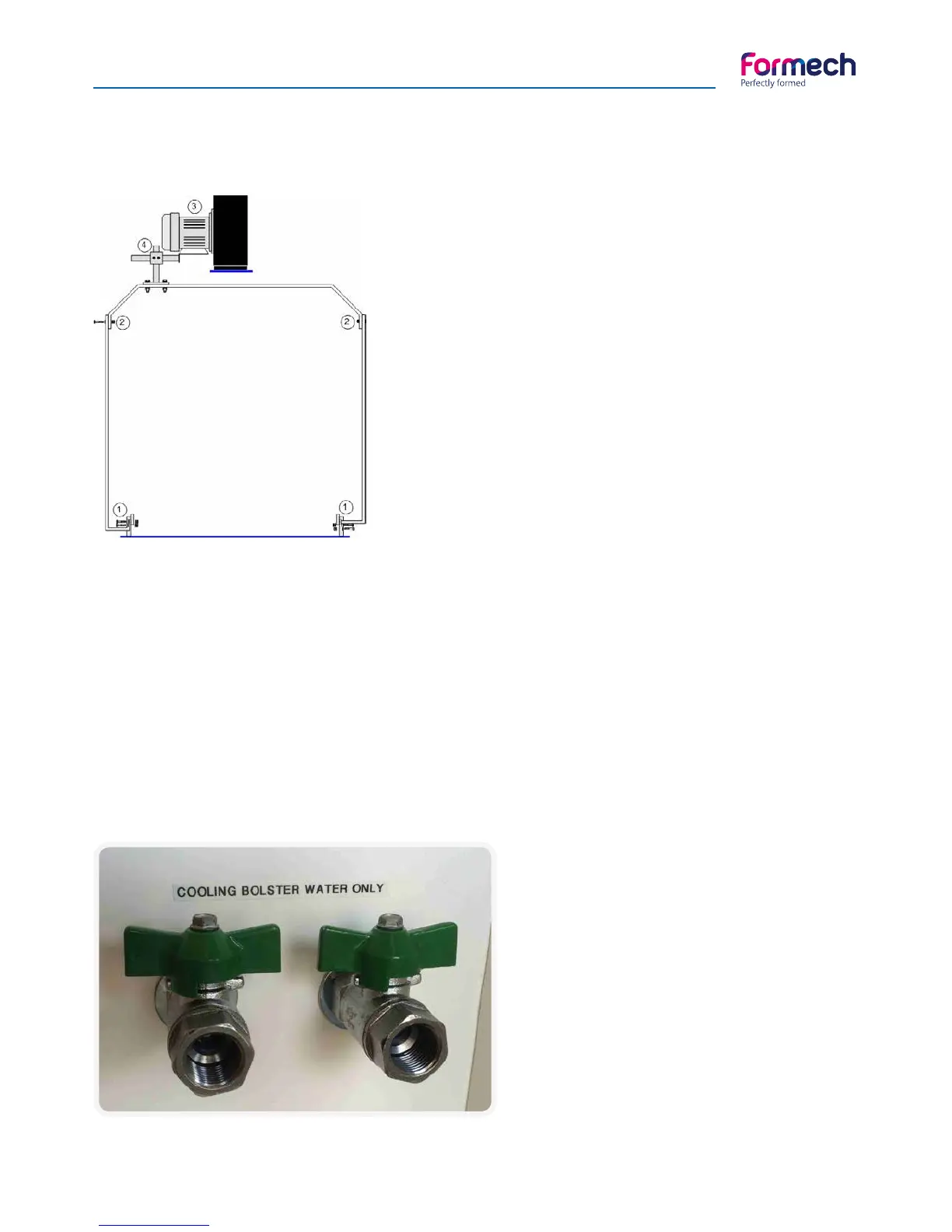

Optional - Connecting the cooling bolster

The cooling Bolster is prefitted to the mould

table. PTFE water pipes are connected between

the underside of the bolster and the back panel.

Connect the feed and return pipes of the

temperature controlled water supply to the 2

fittings mounted on the rear of the machine.

Fitting are are 3/8” BSP.

Loading...

Loading...