30

Operation - Heater Settings

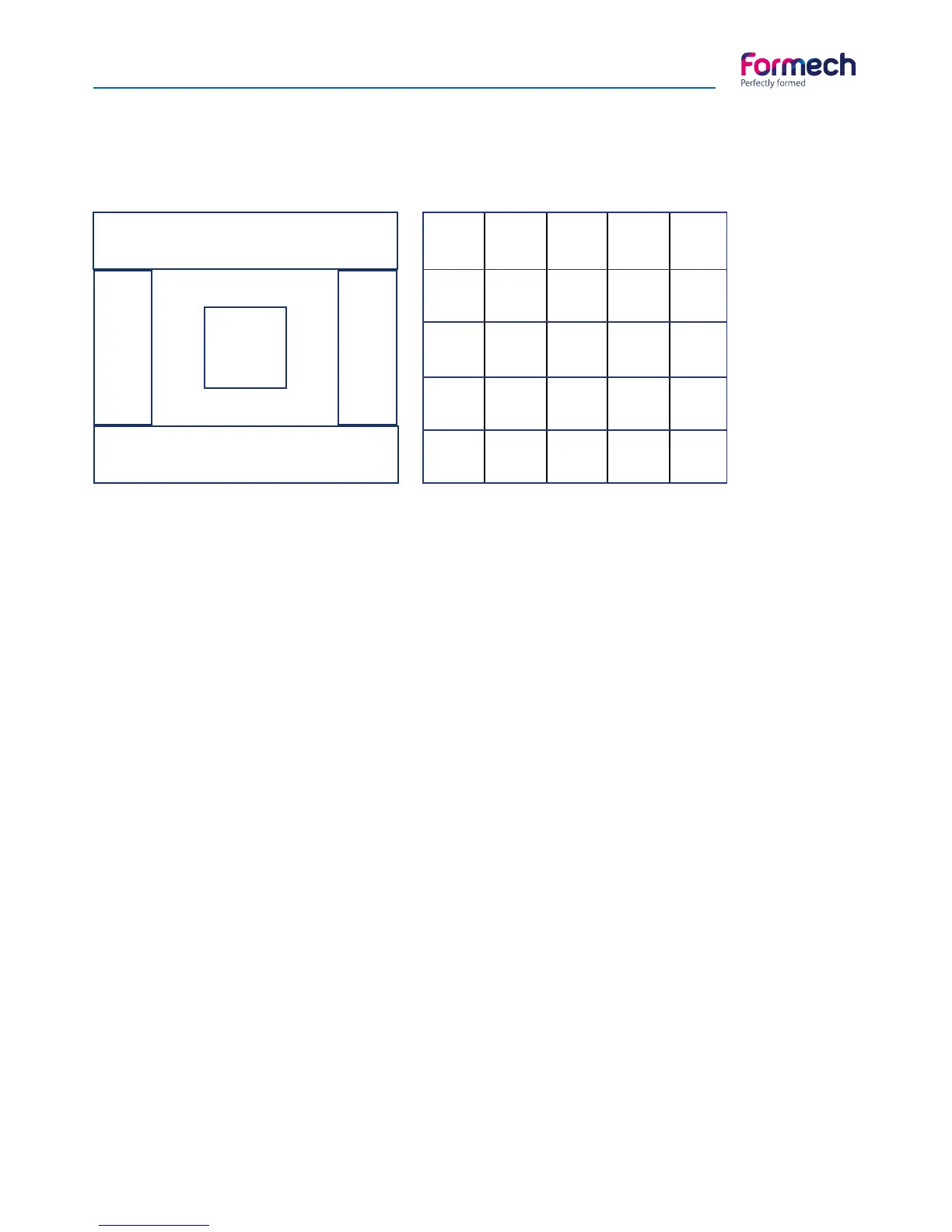

Heater controls & heater arrangement

1 23

4

5

6

Front

686PT Zone layout

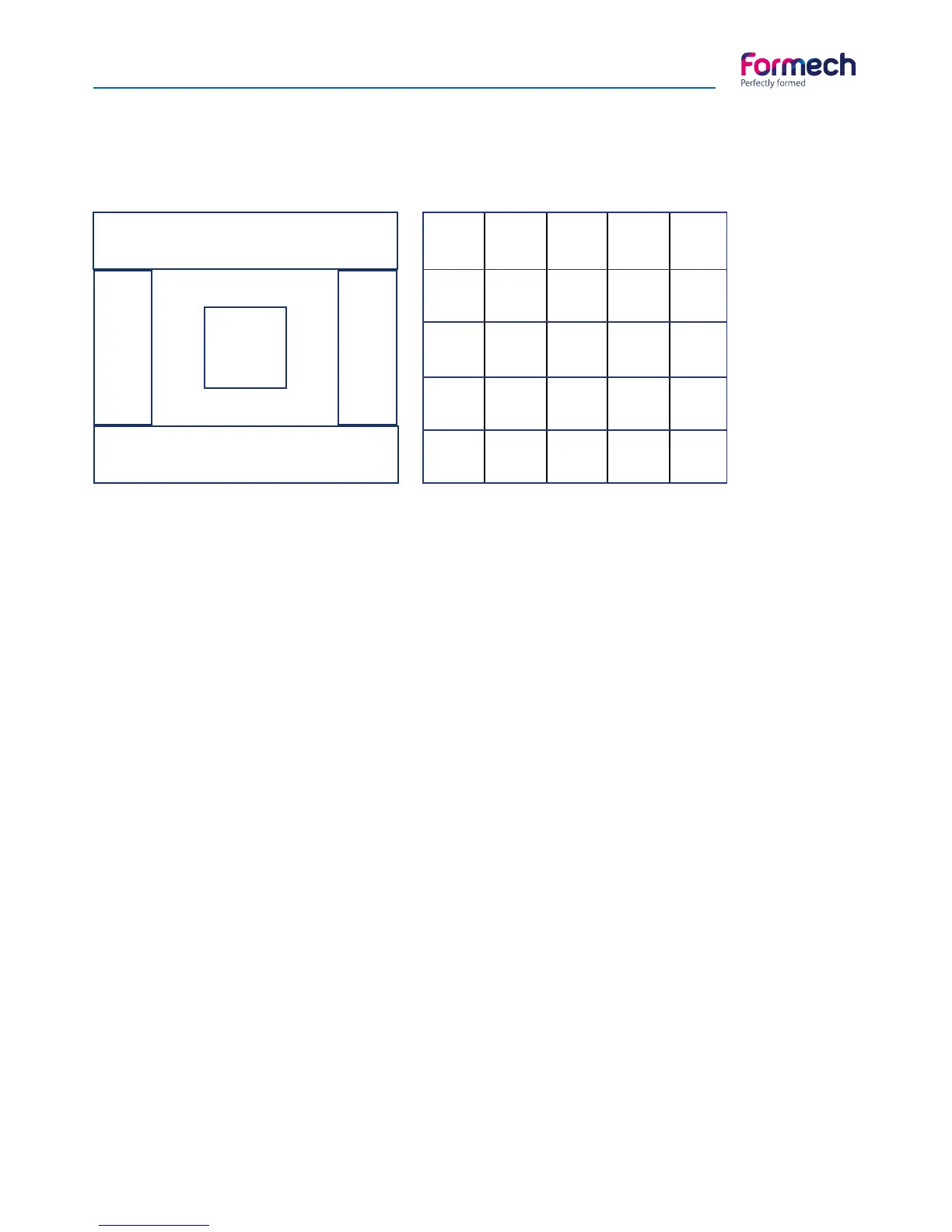

300W 300W 300W 300W 300W

300W 250W 250W 250W 300W

300W 250W 250W 250W 300W

300W 250W 250W 250W 300W

300W 300W 300W 300W 300W

Heating zone control and adjustment

The heating zone control is adjusted through the touch screen. The quartz heaters are designed to heat

the plastic rapidly without burning the surface. The time required to heat the plastic sheet remains fairly

constant.

Heater movement is manually operated – always use the blue handle. Operators are able to send the heater

partially back to check the condition of the plastic and then bring it forward to continue the heating process.

There are 6 controllable heat zones allowing the operator to either switch off zones not required or adjust

the individual zone outputs in 1% increments from 0-100%.

Individual zones may be set up to provide even heat. To achieve the best results set the inner zones lower

than the outer zones. The rear of the heater will always run hotter than the front. The inner zones retain heat

more and outer zones lose the heat more quickly. When using reducing frames the zones not in use should

be turned down or OFF.

The central 9 heating elements are specified with lower power (250W) than the outside elements to allow

for centrally retained heat. Allow for this heat profile when setting.

Always push heaters over the rear heat shield when not heating plastic. Having set the heaters, slight ad-

justments may have to be made depending on the mould design, plastic type / thickness / colour and the

machine & environment temperature / conditions.

When the heater is in the standby position (rear position) the quartz heater may be set to idle at a lower

level to reduce the machine power consumption.

Loading...

Loading...